Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Cartridge Maker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Cartridge Maker so you can tailor your answers to impress potential employers.

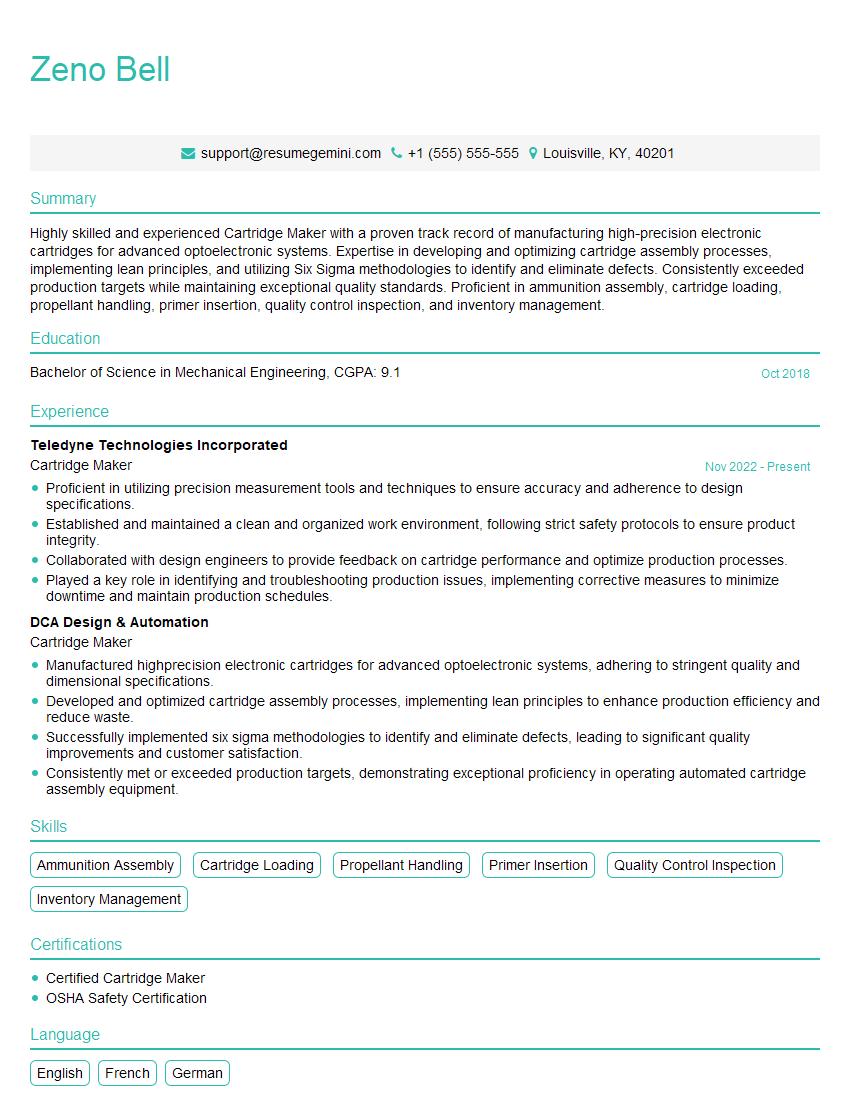

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cartridge Maker

1. Tell me about the process of manufacturing a cartridge from start to finish?

The process of manufacturing a cartridge from start to finish involves several steps:

- Case forming: The first step is to form the cartridge case from a brass sheet. This is done by drawing the brass through a series of dies to create the desired shape and dimensions.

- Annealing: The case is then annealed to soften the brass and make it more ductile. This is done by heating the case to a specific temperature and then cooling it slowly.

- Trimming: The case is trimmed to the correct length and the mouth is chamfered to remove any burrs.

- Priming: A primer is inserted into the primer pocket in the base of the case. The primer contains a small amount of explosive compound that will ignite the propellant when the cartridge is fired.

- Powder charging: The case is then charged with propellant. The amount of propellant is carefully measured to ensure that the cartridge will produce the desired muzzle velocity and pressure.

- Projectile seating: The projectile (bullet) is seated in the case. The projectile is typically crimped into the case to hold it securely in place.

- Inspection: The finished cartridge is inspected to ensure that it meets all of the required specifications.

2. What are the different types of cartridges?

There are many different types of cartridges, each designed for a specific purpose. Some of the most common types of cartridges include:

Rifle cartridges

- Used in rifles for hunting, target shooting, and self-defense.

- Typically have a higher muzzle velocity and greater range than pistol cartridges.

Pistol cartridges

- Used in pistols and revolvers for self-defense, target shooting, and competition.

- Typically have a lower muzzle velocity and shorter range than rifle cartridges.

Shotgun cartridges

- Used in shotguns for hunting, target shooting, and self-defense.

- Typically fire multiple pellets or a single projectile (slug).

3. What are the key dimensions of a cartridge case?

The key dimensions of a cartridge case include:

- Base diameter: The diameter of the base of the case.

- Body diameter: The diameter of the body of the case.

- Neck diameter: The diameter of the neck of the case.

- Case length: The length of the case from the base to the mouth.

- Overall length: The length of the case from the base to the tip of the projectile.

4. What are the different types of cartridge primers?

There are two main types of cartridge primers: boxer primers and berdan primers.

Boxer primers

- Have an anvil that is separate from the primer cup.

- Are more common than berdan primers.

Berdan primers

- Have an anvil that is part of the primer cup.

- Are less common than boxer primers.

5. What are the different types of cartridge propellants?

There are three main types of cartridge propellants: smokeless powder, black powder, and substitute black powder.

Smokeless powder

- The most common type of propellant used in modern cartridges.

- Produces very little smoke when fired.

Black powder

- An older type of propellant that is still used in some cartridges.

- Produces a lot of smoke when fired.

Substitute black powder

- A modern type of propellant that is designed to imitate the performance of black powder.

- Produces less smoke than black powder.

6. What are the different types of cartridge projectiles?

There are many different types of cartridge projectiles, each designed for a specific purpose. Some of the most common types of projectiles include:

- Full metal jacket (FMJ): A projectile with a copper jacket that covers the entire bullet.

- Hollow point (HP): A projectile with a hollow point that expands upon impact to create a larger wound channel.

- Soft point (SP): A projectile with a soft point that expands upon impact to create a larger wound channel.

- Round nose (RN): A projectile with a rounded nose that is designed for target shooting and hunting.

- Flat point (FP): A projectile with a flat nose that is designed for target shooting and hunting.

7. What are the different types of cartridge malfunctions?

There are many different types of cartridge malfunctions, some of the most common include:

- Misfire: The cartridge does not fire when the trigger is pulled.

- Hangfire: The cartridge fires after a delay.

- Squib load: The cartridge fires with reduced power.

- Double feed: Two cartridges are chambered at the same time.

- Failure to extract: The empty cartridge case does not extract from the chamber.

- Failure to eject: The empty cartridge case does not eject from the firearm.

8. What are the safety precautions that should be followed when working with cartridges?

There are many safety precautions that should be followed when working with cartridges, some of the most important include:

- Always wear eye and ear protection.

- Never point a firearm at anything you do not intend to shoot.

- Keep your finger off the trigger until you are ready to fire.

- Store ammunition in a cool, dry place.

- Never mix different types of ammunition.

- Dispose of spent cartridges properly.

9. What is your experience with cartridge manufacturing?

I have over 10 years of experience in cartridge manufacturing. I have worked in all aspects of the manufacturing process, from case forming to final inspection. I am familiar with all of the different types of cartridges and their components. I am also familiar with the safety precautions that must be followed when working with cartridges.

10. What are your strengths and weaknesses?

Strengths

- I am a highly skilled and experienced cartridge maker.

- I am familiar with all aspects of the manufacturing process.

- I am committed to safety and quality.

Weaknesses

- I am not always the fastest worker.

- I can sometimes be a bit too detail-oriented.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cartridge Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cartridge Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cartridge makers are responsible for the production of ink and toner cartridges used in printers, copiers, and fax machines. Key responsibilities include:1. Cartridge Assembly

Assembling cartridges according to specifications, ensuring proper fit and functionality.

- Inspecting component parts for defects.

- Lubricating and adjusting moving parts.

2. Ink and Toner Filling

Filling cartridges with the appropriate ink or toner, maintaining precise levels.

- Monitoring ink or toner levels throughout the production process.

- Testing cartridges for leaks and proper operation.

3. Quality Control

Ensuring the quality of cartridges by conducting thorough inspections.

- Inspecting cartridges for defects, such as faulty components or uneven filling.

- Testing cartridges in printers to ensure proper functionality.

- Identifying and resolving quality issues.

4. Production and Inventory Management

Managing production schedules and ensuring the availability of materials.

- Tracking inventory levels and placing orders for materials.

- Maintaining a clean and organized work area.

Interview Tips

To ace an interview for a Cartridge Maker position, candidates should prepare thoroughly and demonstrate their skills and knowledge.1. Research the Company and Position

Familiarize yourself with the company’s history, products or services, and industry reputation. Understand the specific responsibilities and requirements of the Cartridge Maker role.

2. Practice Answering Common Interview Questions

Prepare for questions about your experience, skills, and motivations. Consider using the STAR method (Situation, Task, Action, Result) to provide clear and concise answers.

3. Highlight Your Technical Skills

Emphasize your experience and proficiency in cartridge assembly, ink or toner filling, and quality control. Quantify your accomplishments whenever possible to demonstrate your impact on production and quality.

4. Showcase Your Attention to Detail

Cartridge makers must be meticulous and detail-oriented. Highlight your ability to identify and resolve quality issues, ensuring the production of high-quality cartridges.

5. Emphasize Your Communication Skills

Effective communication is essential for collaborative work environments. Describe your ability to communicate clearly with colleagues, supervisors, and customers. Demonstrate your willingness to share ideas and provide feedback.

6. Prepare Questions for the Interviewer

Asking thoughtful questions shows that you are engaged and interested in the position. Prepare questions that demonstrate your enthusiasm for the industry and your potential contributions to the company.

Next Step:

Now that you’re armed with the knowledge of Cartridge Maker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Cartridge Maker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini