Are you gearing up for a career in Casing Tier? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Casing Tier and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

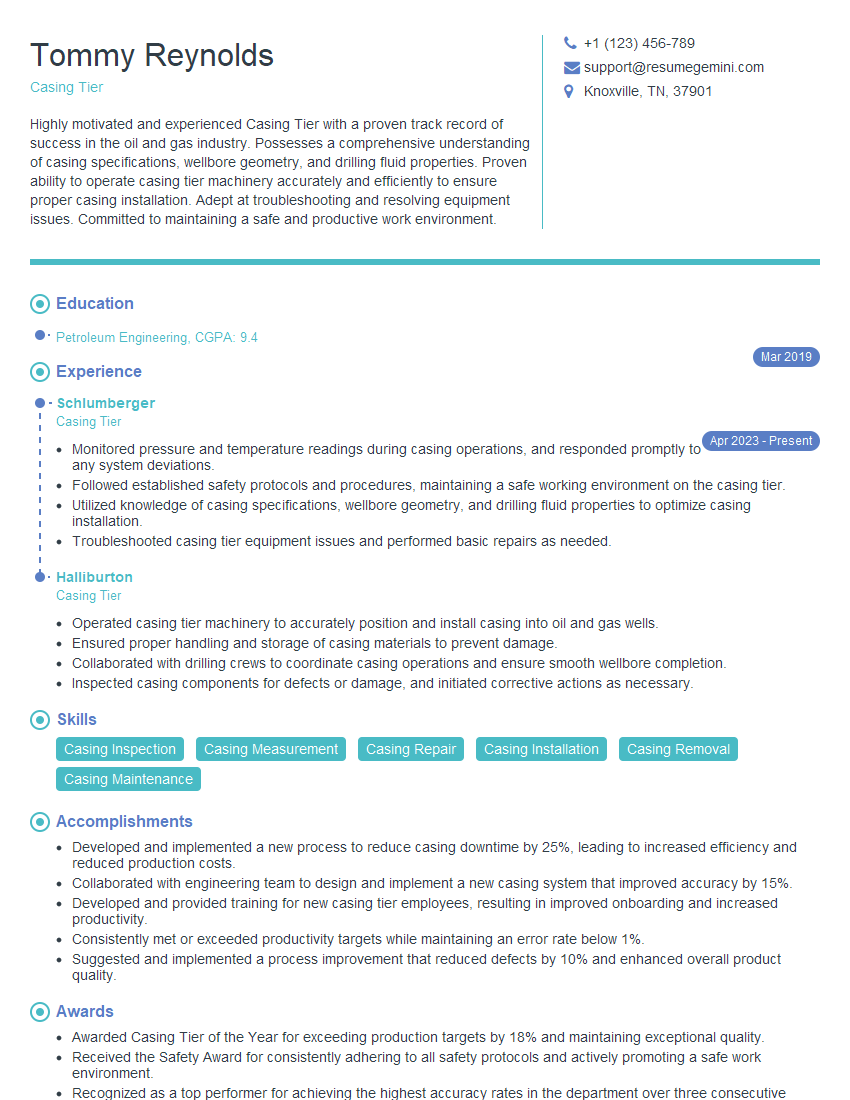

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Casing Tier

1. What factors do you consider when selecting casing for a well?

When selecting casing for a well, I consider several factors, including:

- The depth of the well and the expected pressures that the casing will need to withstand.

- The type of fluid that will be produced from the well, such as oil, gas, or water.

- The corrosive nature of the produced fluids and the formation fluids.

- The temperature of the produced fluids and the formation fluids.

- The environmental regulations that apply to the well.

2. What are the different types of casing connections and their advantages and disadvantages?

Threaded Connections

- Advantages: Simple to run and make up, low cost, good sealing performance.

- Disadvantages: Can be prone to galling and cross-threading, not suitable for high-pressure applications.

Buttress Connections

- Advantages: High strength, good sealing performance, resistant to galling and cross-threading.

- Disadvantages: More complex to run and make up, higher cost.

Coupled Connections

- Advantages: High strength, good sealing performance, easy to make up.

- Disadvantages: More complex to run, higher cost, potential for leaks.

3. What are the key considerations when designing a casing running program?

When designing a casing running program, I consider:

- The casing design, including the casing size, weight, and grade.

- The drilling fluid properties and the compatibility with the casing.

- The running equipment, such as the casing running tool and the running crew.

- The wellbore conditions, such as the hole size and the presence of any obstructions.

- The casing running sequence and the required makeup torque.

4. How do you calculate the casing running weight and what factors do you consider?

The casing running weight is calculated using the following formula:

Casing Running Weight (lbs) = Casing Weight (lbs/ft) x Casing Length (ft) x Running Factor

The running factor considers several factors, including:

- The type of casing connection.

- The wellbore conditions.

- The drilling fluid properties.

- The running crew’s experience.

5. What are the different methods of casing centralization and when do you use each method?

The different methods of casing centralization include:

- Centralizers: Used to center the casing in the wellbore and prevent it from contacting the formation.

- Standoff Bands: Used to provide a specific clearance between the casing and the wellbore.

- Float Collars: Used to centralize the casing and prevent it from moving axially.

I use these methods based on factors such as the hole size, the casing size, the wellbore conditions, and the casing running program.

6. What are the potential risks and complications that can occur during casing running and how do you mitigate them?

Potential risks and complications during casing running include:

- Casing sticking.

- Casing collapse.

- Casing leaks.

I mitigate these risks by:

- Properly designing the casing running program.

- Using the appropriate running equipment and techniques.

- Monitoring the running process closely.

- Having contingency plans in place to address any potential problems.

7. What are the performance indicators that you monitor during casing running and how do you use them to ensure a successful operation?

I monitor several performance indicators during casing running, including:

- Casing running weight.

- Casing torque.

- Casing drag.

- Mud flow rate and pressure.

I use these indicators to assess the progress of the casing running operation and to identify any potential problems. By monitoring these indicators closely, I can ensure that the operation is conducted safely and efficiently.

8. How do you determine the proper casing setting depth and what factors do you consider?

I determine the proper casing setting depth based on several factors, including:

- The well design.

- The geological formations.

- The drilling fluid properties.

- The casing running program.

I use this information to calculate the casing setting depth and to ensure that the casing is set at a depth that will provide adequate protection for the wellbore.

9. What are the post-casing running procedures that you perform and why are they important?

After casing running, I perform several post-casing running procedures, including:

- Casing pressure test.

- Casing cementing.

- Casing leak test.

These procedures are important because they ensure that the casing is properly installed and that it is providing the necessary protection for the wellbore.

10. What are some of the new technologies and techniques that are being used in casing running and how have they improved the process?

Some of the new technologies and techniques that are being used in casing running include:

- Real-time casing running monitoring systems.

- Advanced casing running tools.

- Improved drilling fluids.

These technologies have improved the casing running process by increasing efficiency, accuracy, and safety.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Casing Tier.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Casing Tier‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Casing Tier

A Casing Tier is responsible for handling and casing various goods in a warehouse or manufacturing environment. This role plays a crucial part in the smooth functioning of warehouse operations, ensuring the accuracy and efficiency of goods handling and storage.

1. Receiving and Inspecting Goods

A Casing Tier is responsible for receiving incoming goods from suppliers or other departments within the organization. They must carefully check and inspect each item to ensure it matches the purchase order, is in good condition, and free of any damages.

2. Sorting and Categorizing Goods

Once goods are received, the Casing Tier is tasked with sorting and categorizing them based on their type, size, or other relevant characteristics. This process is essential for ensuring that goods are stored in the appropriate locations within the warehouse and can be easily retrieved when needed.

3. Preparing Goods for Storage

Casing Tiers prepare goods for storage by wrapping them in protective materials, labeling them with the necessary information, and placing them in designated storage areas. They must adhere to established storage procedures to ensure the safety and integrity of goods.

4. Maintaining Inventory Records

Casing Tiers are responsible for maintaining accurate inventory records, which track the quantity and location of all goods within the warehouse. This information is crucial for managing stock levels, preventing shortages, and ensuring the efficient fulfillment of orders.

5. Loading and Unloading Goods

Casing Tiers may also be involved in loading and unloading goods from trucks or other vehicles. They must operate forklifts or other equipment safely and efficiently to ensure the proper handling of goods during these processes.

Interview Preparation Tips for Casing Tier Candidates

Preparing for a Casing Tier interview can increase your chances of success. Here are some key tips to help you ace the interview:

1. Research the Company and Role

Before the interview, take the time to thoroughly research the company and the specific Casing Tier role you are applying for. This will give you a better understanding of the company’s culture, values, and expectations for the position.

2. Highlight Relevant Skills and Experience

Emphasize your relevant skills and experience during the interview. Focus on your ability to handle and sort goods, maintain inventory records, and operate equipment safely. Provide specific examples of your accomplishments in these areas.

3. Demonstrate Teamwork and Communication Skills

Casing Tiers often work in teams and must have good communication skills. During the interview, highlight your ability to work effectively with others and communicate clearly and concisely.

4. Prepare for Common Interview Questions

Prepare for common interview questions related to the role of a Casing Tier. Practice answering questions about your skills, experience, and why you are interested in the position.

5. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows your interest in the position and the company. Prepare a few questions that demonstrate your understanding of the role and the industry.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Casing Tier, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Casing Tier positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.