Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Detonator Assembler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

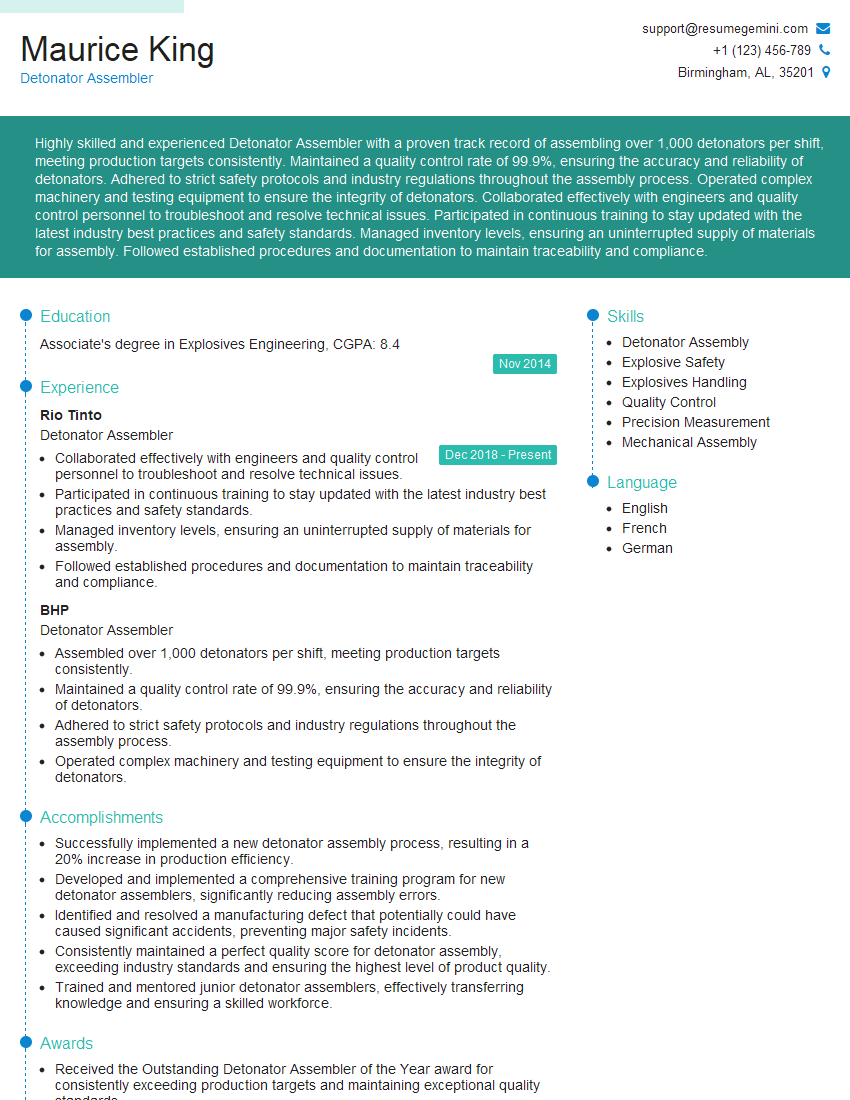

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Detonator Assembler

1. Describe the proper storage and handling procedures for detonators?

- Detonators should be stored in a secure, dry location away from heat and ignition sources.

- Detonators should be handled with care, and never dropped or subject to shock.

- Detonators should always be used in accordance with the manufacturer’s instructions.

2. What are the different types of detonators and what are their uses?

Electric detonators

- Electric detonators are initiated by an electric current.

- They are used in a variety of applications, including mining, construction, and demolition.

Non-electric detonators

- Non-electric detonators are initiated by a chemical reaction.

- They are used in a variety of applications, including mining, construction, and demolition.

3. What are the safety precautions that should be taken when working with detonators?

- Always wear appropriate safety gear, including gloves, eye protection, and a hard hat.

- Never smoke or eat around detonators.

- Never handle detonators if you are under the influence of alcohol or drugs.

- Always follow the manufacturer’s instructions for using detonators.

4. What are the different types of detonator assemblies?

- Single-shot detonator assemblies

- Multiple-shot detonator assemblies

- Delay detonator assemblies

- Sequential detonator assemblies

5. What are the factors that affect the performance of a detonator assembly?

- The type of detonator

- The size of the detonator

- The type of detonator assembly

- The environment in which the detonator is used

6. What are the quality control procedures that are used to ensure the reliability of detonator assemblies?

- Visual inspection

- Electrical testing

- Functional testing

- Environmental testing

7. What are the maintenance procedures that are required for detonator assemblies?

- Regular visual inspection

- Electrical testing

- Functional testing

- Replacement of any damaged components

8. What are the troubleshooting procedures that are used to resolve problems with detonator assemblies?

- Visual inspection

- Electrical testing

- Functional testing

- Replacement of any damaged components

9. What are the training requirements for detonator assemblers?

- Detonator assemblers must be trained in the proper storage, handling, and assembly of detonators.

- Detonator assemblers must be familiar with the different types of detonators and their uses.

- Detonator assemblers must be aware of the safety precautions that must be taken when working with detonators.

10. What are the career opportunities for detonator assemblers?

- Detonator assemblers can work in a variety of industries, including mining, construction, and demolition.

- Detonator assemblers can advance to positions such as quality control inspector or production supervisor.

- Detonator assemblers can also start their own businesses.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Detonator Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Detonator Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Detonator Assembler is responsible for assembling detonator systems for use in explosive devices. This role requires a high level of technical skill and precision, as well as a deep understanding of explosive materials and safety protocols.

1. Assemble Detonator Systems

This involves assembling detonator housings, detonator caps, and other components to create complete detonator systems.

- Follow blueprints and specifications to assemble detonator systems.

- Ensure that all components are properly fitted and secured.

2. Inspect and Test Detonator Systems

This involves visually inspecting and testing detonator systems to ensure they meet quality and safety standards.

- Inspect detonator systems for any defects or damage.

- Conduct electrical tests and other tests to verify functionality.

3. Maintain Production Equipment

This involves maintaining and calibrating the equipment used in the assembly process.

- Clean and lubricate equipment as needed.

- Calibrate equipment to ensure accurate measurements and production.

4. Comply with Safety Protocols

This involves adhering to strict safety protocols to prevent accidents and injuries.

- Wear appropriate personal protective equipment (PPE).

- Follow established safety procedures for handling explosive materials.

Interview Tips

To ace your Detonator Assembler interview, it is crucial to prepare thoroughly and showcase your skills and knowledge.

1. Research the Industry

Before the interview, take time to research the detonator assembly industry and the specific company you are applying to.

- Understand the latest technologies and trends in detonator assembly.

- Review the company’s website, news articles, and industry publications.

2. Highlight Your Technical Abilities

Emphasize your technical skills and experience in detonator assembly. Quantify your accomplishments and provide specific examples of your work.

- Describe the types of detonator systems you have assembled.

- Explain the quality control measures you have implemented.

3. Demonstrate Safety Awareness

Safety is paramount in this field. Highlight your knowledge of safety protocols and your commitment to adhering to them.

- Discuss your experience with handling explosive materials.

- Explain how you ensure the safety of yourself and others in the workplace.

4. Anticipate Industry-Specific Questions

Interviewers may ask questions specific to the detonator assembly industry. Be prepared to answer questions about:

- The different types of explosives used in detonator systems.

- The safety regulations governing the storage and handling of explosives.

5. Practice Your Communication Skills

Detonator Assemblers often need to communicate technical information clearly and concisely to colleagues and supervisors.

- Practice explaining technical concepts in a non-technical way.

- Prepare to answer questions about your communication style.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Detonator Assembler interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.