Feeling lost in a sea of interview questions? Landed that dream interview for Dust Mop Maker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Dust Mop Maker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

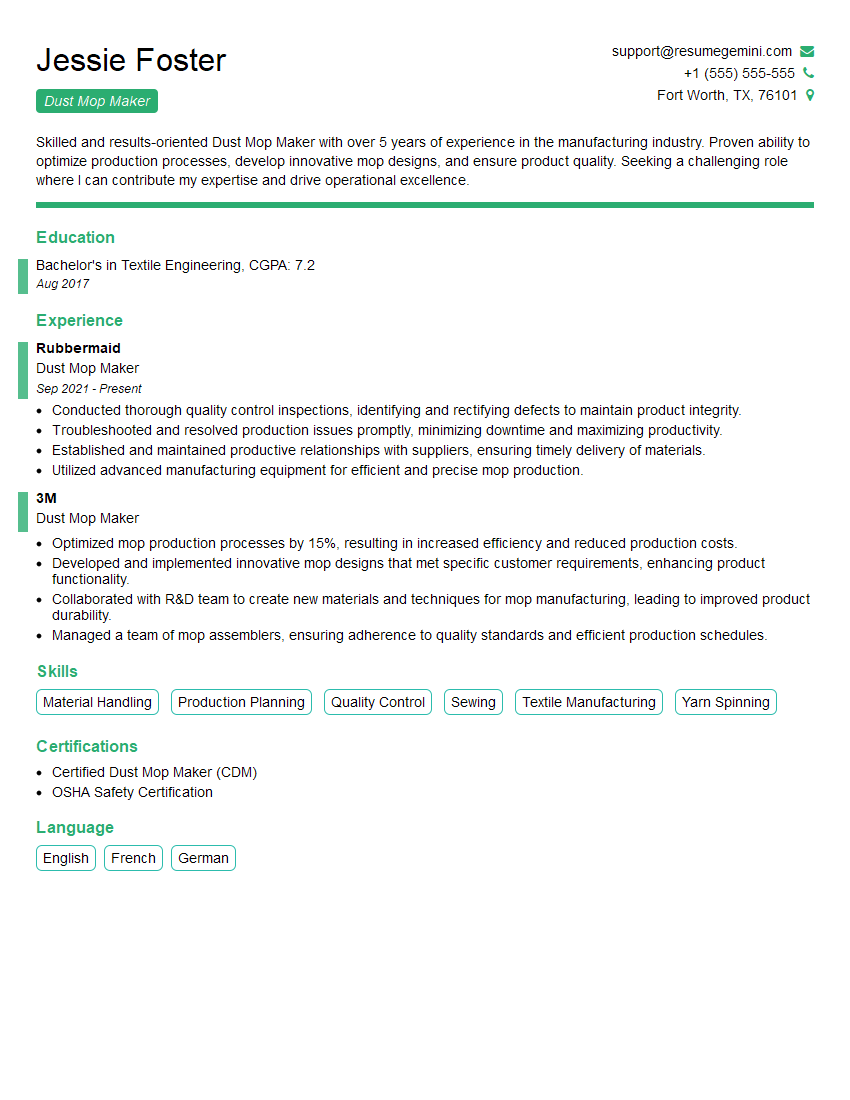

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dust Mop Maker

1. What are the key factors to consider when selecting materials for dust mop heads?

- Fiber type: Natural or synthetic fibers can be used, each with different properties (e.g., absorbency, durability).

- Fiber length and thickness: These affect the mop’s ability to trap dust and debris.

- Density and weight: The weight of the mop head influences its coverage and effectiveness.

- Chemical resistance: The materials should be resistant to cleaning agents and chemicals used in cleaning.

- Cost and availability: The materials must fit within the budget and be readily available.

2. Describe the different types of dust mop frames and their applications.

- Rectangular or square in shape, with a flat surface for mopping floors.

- Suitable for dusting large areas quickly and easily.

- Made of metal or plastic, with a frame that holds strings or loops of yarn.

- Effective for removing dust and dirt from corners, edges, and hard-to-reach areas.

- Feature a lightweight frame with a microfiber pad attached.

- Highly effective in trapping and releasing dust and allergens due to microfiber’s electrostatic properties.

Flat dust mop frames:

String dust mop frames:

Microfiber dust mop frames:

3. Explain the process of manufacturing dust mop heads.

- Fiber preparation: The fibers are cut, blended, and treated to enhance their properties.

- Yarn spinning: The fibers are twisted and spun into yarns.

- Fabric weaving or knitting: The yarns are woven or knitted into a fabric for the mop head.

- Head construction: The fabric is cut and sewn into different shapes and sizes.

- Quality control: The finished mop heads are inspected to meet specifications and standards.

4. How do you ensure the durability and longevity of dust mop heads?

- Selecting high-quality materials: Using durable fibers and materials that can withstand wear and tear.

- Proper construction: Reinforcing the mop heads with stitching, binding, or other techniques to prevent fraying or tearing.

- Washing instructions: Providing clear instructions on how to properly wash and maintain the mop heads to prolong their lifespan.

- Feedback from users: Collecting feedback from customers to identify any areas for improvement in terms of durability.

5. Discuss the importance of dust mop handles and their ergonomic design.

- Comfort: The handles should be designed to fit comfortably in the user’s hands, reducing strain and fatigue during extended use.

- Durability: The handles should be made of durable materials that can withstand constant use and accidental drops.

- Length and adjustability: The handles should be adjustable to accommodate different user heights and cleaning tasks.

- Ergonomic grip: The handles should feature a non-slip grip to prevent hand strain and improve control.

6. Explain the difference between wet and dry dusting and when to use each method.

- Uses a damp cloth or mop to remove dust and dirt.

- More effective in trapping dust and preventing it from being redistributed.

- Suitable for surfaces that are not easily damaged by moisture, such as floors and countertops.

- Uses a dry cloth or brush to remove dust and debris.

- Less effective in trapping dust but does not leave moisture on surfaces.

- Suitable for surfaces that are sensitive to moisture, such as electronics and furniture.

Wet dusting:

Dry dusting:

7. Describe the different types of dust mop cleaning solutions and their applications.

- All-purpose cleaners: Suitable for general dusting and cleaning of most surfaces.

- Specialized cleaners: Designed for specific surfaces, such as wood, glass, or electronics.

- Disinfectant cleaners: Contain antimicrobial agents to kill germs and bacteria.

- Natural cleaners: Made from plant-based ingredients, such as vinegar or lemon juice.

8. Explain the importance of proper dust mop maintenance and storage.

- Regular washing and drying: Prevents the buildup of dust and dirt, prolonging the mop’s lifespan.

- Proper storage: Store mops in a clean, dry place to prevent mold and mildew growth.

- Inspection and repairs: Regularly check the mop heads and frames for damage or wear and make repairs as necessary.

- Training and education: Train staff on proper mop maintenance and handling to ensure longevity.

9. Discuss the latest trends and innovations in dust mop technology.

- Microfiber technology: Microfiber mop heads have become increasingly popular due to their high efficiency in trapping dust and allergens.

- Electrostatic mops: These mops use electrostatic charges to attract and hold dust, reducing the need for chemical cleaners.

- Disposable dust mop heads: Disposable mop heads offer convenience and reduce the need for laundering.

- Smart mops: Some mops now feature sensors and connectivity, enabling them to track cleaning data and provide usage insights.

10. How do you approach quality control in dust mop manufacturing?

- Raw material inspection: Checking the quality and consistency of incoming fibers and materials.

- In-process inspection: Monitoring key manufacturing processes to ensure compliance with specifications.

- Finished product testing: Testing the finished mop heads and frames against performance criteria.

- Regular audits: Conducting audits to identify areas for improvement and maintain high standards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dust Mop Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dust Mop Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Dust Mop Maker plays a crucial role in the manufacturing sector, specializing in the production of dust mops, essential tools for maintaining cleanliness and hygiene in various settings.

1. Dust Mop Production and Assembly

The primary responsibility involves operating and maintaining dust mop making machines to produce high-quality mops. This includes:

- Preparing and setting up the machine according to specifications

- Feeding raw materials (e.g., yarn, fabric) into the machine

- Monitoring the production process and making necessary adjustments

- Inspecting finished products for defects and ensuring adherence to quality standards

2. Quality Control and Maintenance

Ensuring the consistent quality of dust mops is paramount. Key tasks include:

- Conducting regular inspections and testing to verify product quality

- Identifying and troubleshooting any issues that arise during production

- Maintaining and calibrating equipment to ensure optimal performance

3. Work Environment and Safety

Maintaining a safe and efficient work environment is essential. Responsibilities include:

- Adhering to established safety protocols and regulations

- Maintaining a clean and organized work area

- Using personal protective equipment (PPE) as required

- Reporting any hazards or potential safety concerns

4. Production Reporting and Inventory Management

To ensure smooth production and inventory management:

- Maintaining accurate records of production output

- Monitoring inventory levels and replenishing stocks as needed

- Communicating production status and any relevant information to supervisors

Interview Tips

To ace an interview for the Dust Mop Maker position, consider the following tips:

1. Research the Company and Role

Research the company, its values, and the specific role to gain insights into their needs. This understanding will help tailor your answers and demonstrate your interest.

2. Highlight Relevant Skills and Experience

Emphasize skills and experiences that align with the job responsibilities, such as operating dust mop making machines, maintaining quality standards, and adhering to safety protocols.

3. Prepare for Technical Questions

Be prepared to answer questions related to dust mop production techniques, quality control measures, and troubleshooting. Demonstrate your knowledge and problem-solving abilities.

4. Showcase Teamwork and Communication

Dust Mop Makers often work in teams and interact with supervisors and colleagues. Highlight your ability to collaborate effectively and communicate clearly.

5. Emphasize Safety and Attention to Detail

Safety and attention to detail are critical in this role. Explain your commitment to adhering to safety protocols and your meticulous approach to maintaining quality standards.

6. Prepare Questions for the Interviewer

Prepared questions show your engagement and interest. Consider asking about the company’s production goals, quality expectations, or opportunities for growth within the organization.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Dust Mop Maker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.