Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Flange Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Flange Machine Operator so you can tailor your answers to impress potential employers.

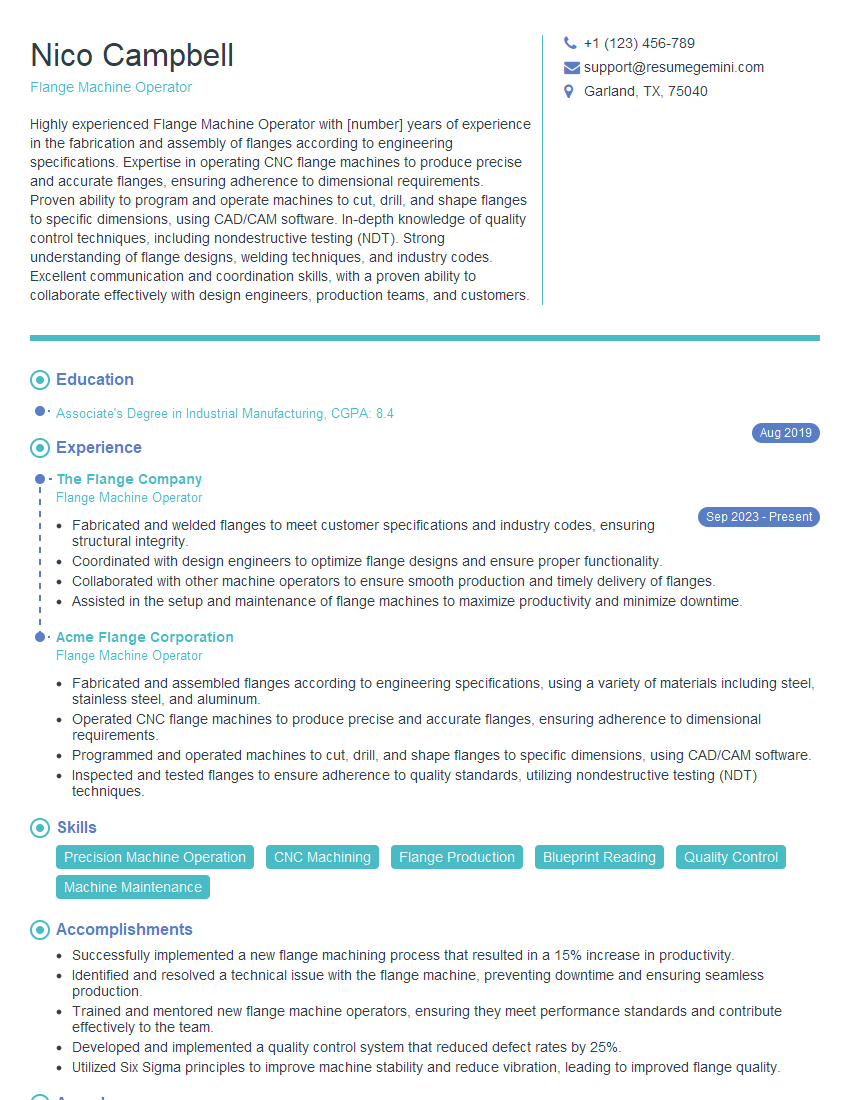

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Flange Machine Operator

1. What are the different types of flange machines and their uses?

There are various types of flange machines, each designed for specific applications:

- Horizontal Flange Facing Machine: Used for machining flat surfaces on flanges, typically for large-diameter pipes.

- Vertical Flange Facing Machine: Suitable for machining flanges mounted on vertical pipes, providing greater flexibility.

- Portable Flange Facing Machine: Compact and portable machines designed for on-site flange machining in confined spaces.

- Pipe Bevelling Machine: Used for preparing pipe ends for welding, creating accurate bevels for optimal joint strength.

2. Explain the steps involved in flange machining.

Surface Preparation

- Inspect the flange for damage or inconsistencies.

- Clean the surface to remove any dirt, rust, or debris.

Machine Setup

- Choose the appropriate flange machine and tooling.

- Secure the flange on the machine table.

- Set the cutting parameters (speed, feed rate, depth of cut).

Machining

- Start the machine and carefully maneuver the cutting tool.

- Monitor the machining process and make adjustments as needed.

Inspection and Finishing

- Inspect the machined surface for accuracy and smoothness.

- Perform any necessary finishing operations (e.g., deburring, polishing).

3. What are the common materials used in flange manufacturing and their properties?

- Steel: High strength and durability, suitable for various applications.

- Stainless Steel: Corrosion-resistant, often used in chemical and food industries.

- Aluminum: Lightweight and corrosion-resistant, ideal for aerospace and marine applications.

- Nickel Alloys: Highly corrosion-resistant and heat-resistant, used in demanding environments.

- Titanium: Exceptional strength-to-weight ratio, used in high-performance industries.

4. How do you maintain a flange machine for optimal performance?

- Regular Cleaning and Lubrication: Remove debris and apply lubricant to moving parts.

- Tool Inspection and Replacement: Inspect cutting tools for wear and replace when necessary.

- Calibration and Adjustment: Ensure the machine is calibrated regularly for accurate measurements.

- Electrical and Mechanical Maintenance: Inspect wiring, electrical components, and mechanical systems.

- Training and Supervision: Ensure operators are properly trained and supervised to prevent misuse.

5. What factors influence the choice of cutting tools for flange machining?

- Material of the Flange: Choose tools suitable for the specific material being machined.

- Type of Machining Operation: Select tools designed for the desired operation (e.g., facing, bevelling).

- Machine Capabilities: Consider the power and speed of the flange machine when selecting tools.

- Cost and Availability: Factor in the cost and availability of different tool options.

- Tool Life and Performance: Evaluate the tool’s durability and ability to maintain cutting accuracy over time.

6. How do you minimize vibrations during flange machining?

- Proper Machine Mounting: Ensure the machine is securely mounted on a stable surface.

- Tool Balancing: Balance cutting tools to reduce imbalances and vibrations.

- Correct Feeds and Speeds: Use appropriate cutting parameters to avoid excessive vibrations.

- Cutting Fluid: Apply cutting fluid to reduce friction and dampen vibrations.

- Vibration Dampening Devices: Install devices such as vibration isolators or dampers to absorb vibrations.

7. What safety precautions should be observed when operating a flange machine?

- Proper Training and Certification: Ensure operators are trained and certified to operate the machine.

- Personal Protective Equipment (PPE): Wear appropriate PPE, including safety glasses, gloves, and ear protection.

- Machine Guards: Keep all safety guards in place and ensure they are functioning properly.

- Tool Inspection: Inspect tools regularly and do not use damaged or defective tools.

- Machine Maintenance: Perform regular maintenance and repairs to ensure the machine is in good working condition.

8. Explain the importance of flange facing in pipeline systems.

- Leak Prevention: Ensures a tight seal between flanges to prevent leaks and maintain system integrity.

- Surface Preparation: Creates a smooth and even surface for optimal gasket sealing.

- Corrosion Resistance: Removes corrosion and pitting, which can compromise the gasket seal.

- Reduced Maintenance: Regular flange facing can prevent premature gasket failure and reduce maintenance costs.

- Safety Enhancements: Proper flange facing ensures the safety and reliability of the pipeline system.

9. How do you inspect flange faces for defects and assess their severity?

- Visual Inspection: Examine flange faces for any visible cracks, gouges, or other defects.

- Ultrasonic Testing: Use ultrasonic waves to detect subsurface defects that may not be visible.

- Magnetic Particle Inspection: Apply magnetic particles to the flange face to reveal surface-breaking cracks.

- Dye Penetrant Inspection: Apply a dye penetrant to the flange face to detect surface discontinuities.

- Severity Assessment: Evaluate the size, location, and type of defect to determine its severity and potential impact on gasket sealing.

10. What are some common flange facing mistakes and how can they be avoided?

- Incorrect Tool Selection: Using the wrong tool for the flange material or operation can damage the flange face.

- Excessive Cutting Depth: Removing too much material can weaken the flange and compromise sealing.

- Chattering: Vibration during cutting can create a rough surface that affects gasket sealing.

- Improper Machine Setup: Incorrectly setting up the machine can lead to inaccurate cuts or damage to the flange.

- Avoidance of Machine Maintenance: Neglecting regular maintenance can result in poor cutting performance and increased risk of flange damage.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Flange Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Flange Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Flange Machine Operators are primarily responsible for operating and maintaining flange machines used in the production of various industrial components. Their key duties include:

1. Machine Operation and Maintenance

Operate flange machines to produce flanges according to specifications.

- Set up and adjust machine parameters, including speed, feed rate, and tool selection.

- Monitor machine performance and make necessary adjustments to ensure optimal operation.

- Perform routine maintenance and repairs on the machine, including lubrication, cleaning, and troubleshooting.

2. Production Process Monitoring

Monitor production processes to ensure quality and efficiency.

- Inspect flanges for defects and ensure they meet dimensional and quality standards.

- Identify and address production bottlenecks and inefficiencies.

- Record production data and report any deviations from expected outcomes.

3. Material Handling

Handle and transport flanges and other materials safely and efficiently.

- Load and unload flanges onto the machine and conveyors.

- Operate forklifts or other equipment to move materials within the production area.

- Ensure proper storage and inventory management of flanges and related materials.

4. Quality Control

Contribute to maintaining high-quality flange production.

- Monitor and record flange dimensions, surface finishes, and other quality parameters.

- Conduct periodic inspections and testing to ensure flanges meet specifications.

- Identify and resolve non-conformance issues.

Interview Tips

To ace the interview for a Flange Machine Operator position, consider the following preparation tips:

1. Research the Company and Industry

Demonstrate your interest and knowledge by researching the company’s website, industry trends, and relevant news.

- Identify the company’s products, services, and target market.

- Learn about the role of flange machines in the industry.

- Prepare questions that showcase your understanding and enthusiasm.

2. Highlight Your Technical Skills

Emphasize your proficiency in operating flange machines and maintaining production processes.

- Describe your experience in setting up, adjusting, and troubleshooting machines.

- Quantify your accomplishments in monitoring production, identifying bottlenecks, and improving efficiency.

- Highlight any certifications or training you have received.

3. Demonstrate Attention to Detail

Flange Machine Operators must be meticulous and pay attention to detail.

- Provide examples of how you ensure accuracy in flange inspection and measurement.

- Describe your approach to identifying and resolving quality issues.

- Explain how you maintain a clean and organized work environment.

4. Emphasize Teamwork and Communication Skills

Flange Machine Operators often work in teams and communicate with production supervisors and quality control personnel.

- Share experiences where you have effectively collaborated with colleagues.

- Describe how you communicate production data and quality reports.

- Indicate your willingness to learn from others and contribute to the team’s success.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Flange Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.