Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Hose Maker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Hose Maker so you can tailor your answers to impress potential employers.

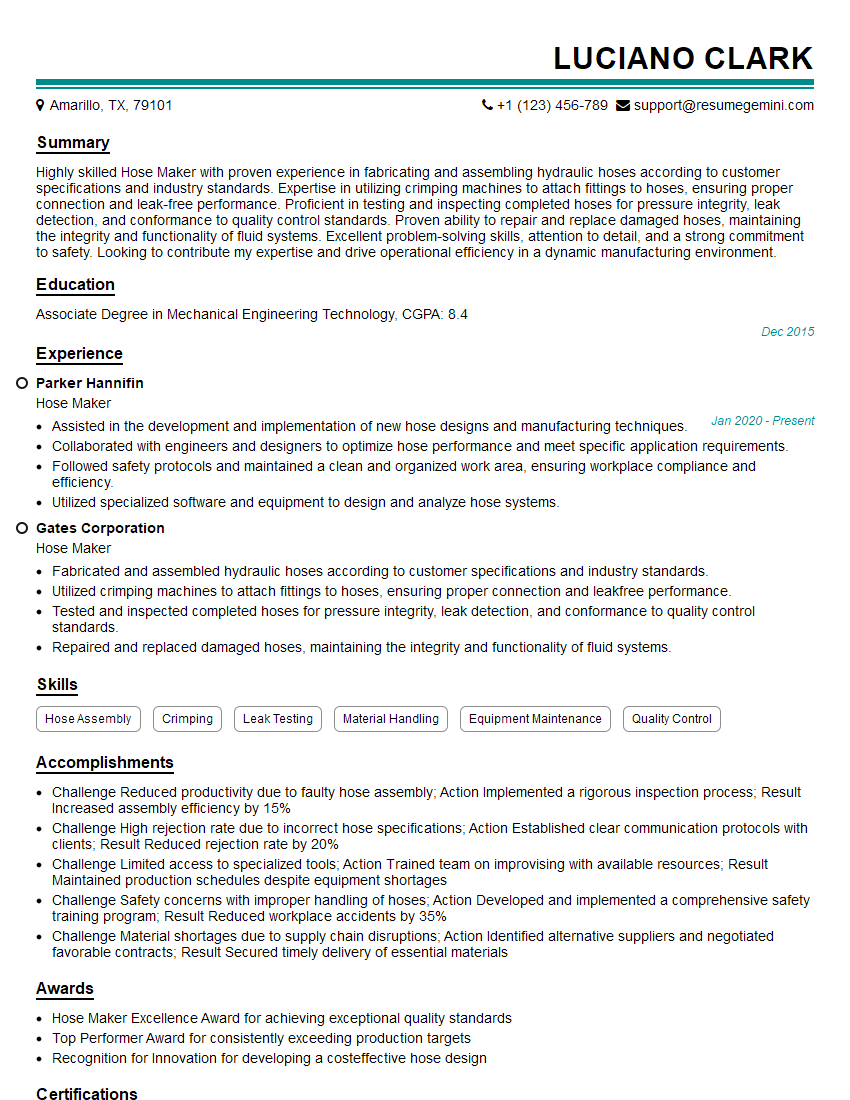

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hose Maker

1. What type of materials are used in hose making, and how do you determine the appropriate material for a specific application?

The various types of materials used in hose making are as follows:

- Rubber: Natural or synthetic rubber is used for hoses that require flexibility and durability. It is resistant to abrasion and chemicals.

- Plastic: Polyethylene, polypropylene, and PVC are used for hoses that are lightweight, flexible, and resistant to corrosion. They are often used in automotive and plumbing applications.

- Metal: Stainless steel, aluminum, and brass are used for hoses that require high strength and durability under extreme pressure and temperature conditions.

- Composite materials: These combine different materials to achieve specific properties, such as flexibility and strength. They are commonly used in high-performance applications.

To determine the appropriate material for a specific application, I consider factors such as:

- Pressure and temperature ratings

- Chemical compatibility

- Abrasion resistance

- Flexibility and bend radius

- Weight and cost constraints

2. How do you calculate the pressure rating of a hose?

Pressure rating calculation

The pressure rating of a hose is determined based on its material properties, construction, and design. The calculation involves:

- Determining the material’s hoop stress

- Calculating the wall thickness based on the desired pressure rating

- Considering safety factors and industry standards

Additional factors

In addition, other factors that influence pressure rating include:

- Hose diameter and length

- Temperature and pressure fluctuations

- Environmental conditions

3. What are the common types of hose fittings, and how do you ensure proper sealing?

There are various types of hose fittings used in hose making, including:

- Compression fittings: These fittings use a ferrule to compress the hose onto the fitting, providing a secure and leak-proof connection.

- Barb fittings: These fittings have a barbed end that is inserted into the hose, creating a friction fit that prevents the hose from slipping off.

- Flange fittings: These fittings use bolts or clamps to connect the hose to a flange, providing a high-pressure and leak-proof connection.

To ensure proper sealing, I follow these steps:

- Inspecting the hose and fittings for damage or defects

- Cleaning and lubricating the fittings and hose ends

- Properly aligning and inserting the hose into the fitting

- Tightening the fitting according to the manufacturer’s specifications

- Testing the connection for leaks before putting the hose into service

4. How do you troubleshoot and repair a leaking hose?

When troubleshooting a leaking hose, I follow a systematic approach:

- Identify the location of the leak by visual inspection and pressure testing

- Determine the cause of the leak, such as a damaged fitting, worn hose, or improper installation

For repairs, I take the following steps:

- Replace damaged fittings or hose sections

- Tighten or adjust fittings to ensure proper sealing

- Apply sealant or tape to damaged areas

- Retest the hose for leaks before putting it back into service

5. What are the safety precautions you observe while working with high-pressure hoses?

When working with high-pressure hoses, I adhere to the following safety precautions:

- Inspecting hoses regularly for damage, wear, or leaks

- Never exceeding the pressure rating of the hose

- Wearing appropriate PPE, including gloves, safety glasses, and protective clothing

- Using proper tools and equipment for hose handling and maintenance

- Keeping a safe distance from pressurized hoses during operation

- Releasing pressure from hoses before disconnecting or making repairs

6. How do you determine the bend radius of a hose, and why is it important?

The bend radius of a hose is the minimum radius to which it can be bent without causing damage or affecting its performance. I determine the bend radius based on the hose material, construction, and pressure rating.

The importance of bend radius lies in the following:

- Preventing hose kinking, which restricts flow and increases pressure

- Maintaining the structural integrity of the hose under pressure

- Ensuring proper flow characteristics and preventing premature hose failure

7. What techniques do you use for hose fabrication?

I am proficient in various hose fabrication techniques, including:

- Cutting hoses to the desired length using specialized cutting tools

- Assembling hoses with fittings using compression, barb, or flange methods

- Applying sealant or tape to ensure leak-proof connections

- Testing hose assemblies for leaks and pressure integrity

8. How do you ensure quality control in hose production?

I implement the following quality control measures in hose production:

- Establishing and adhering to documented procedures and specifications

- Inspecting raw materials and components for defects before use

- Monitoring production processes and making adjustments as needed

- Conducting regular testing and inspections of finished hose assemblies

- Maintaining proper documentation and records for traceability and quality assurance

9. What are the latest trends or innovations in hose manufacturing?

The hose manufacturing industry is constantly evolving, with new trends and innovations emerging:

- Development of lightweight, flexible, and durable materials

- Advancements in composite hose technology for high-pressure and harsh environments

- Integration of sensors and smart technologies into hoses for monitoring and control

- Automation and digitalization in production processes to improve efficiency and quality

- Research on biodegradable and environmentally friendly hose materials

10. How do you stay updated with the latest developments in the field?

To stay updated with the latest developments in the hose manufacturing field, I engage in the following activities:

- Attending industry conferences and exhibitions

- Reading technical journals and publications

- Participating in online forums and discussion groups

- Networking with professionals in the hose industry

- Conducting research and exploring new technologies and materials

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hose Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hose Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hose Makers are responsible for manufacturing and assembling hoses used in various industries. Their key responsibilities include:

1. Hose Fabrication

· Cutting and preparing hose materials to specified lengths

· Assembling hose components, including fittings, couplings, and clamps

· Using specialized equipment to connect and seal hose components

2. Quality Inspection

· Inspecting hoses for defects or leaks using testing equipment

· Ensuring hoses meet required specifications and standards

· Maintaining quality control records

3. Equipment Maintenance

· Keeping hose-making equipment clean and operational

· Identifying and troubleshooting equipment malfunctions

· Calibrating and maintaining testing equipment

4. Inventory Management

· Monitoring inventory levels of hose materials and components

· Ordering and receiving supplies as needed

· Maintaining organized and accessible storage areas

Interview Tips

To ace the interview for a Hose Maker position, candidates can follow these tips:

1. Research the Company and Position

· Visit the company’s website to learn about their products, services, and culture

· Review the job description thoroughly to understand the specific responsibilities

· Identify any relevant experience or skills you have that align with the requirements

2. Prepare for Technical Questions

· Anticipate questions related to hose assembly techniques, equipment operation, and quality control

· Practice answering questions related to hose materials, specifications, and industry standards

· Prepare examples of your problem-solving abilities and experience troubleshooting equipment

3. Highlight Relevant Experience

· Emphasize your previous experience in hose manufacturing, assembly, or related fields

· Quantify your accomplishments and provide specific examples of your contributions

· Explain how your skills and experience make you a suitable candidate for the position

4. Demonstrate Strong Work Ethic

· Explain your attention to detail and commitment to producing high-quality work

· Show your willingness to work independently and as part of a team

· Highlight your ability to meet deadlines and handle pressure

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Hose Maker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.