Are you gearing up for an interview for a Mallet Cutter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Mallet Cutter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

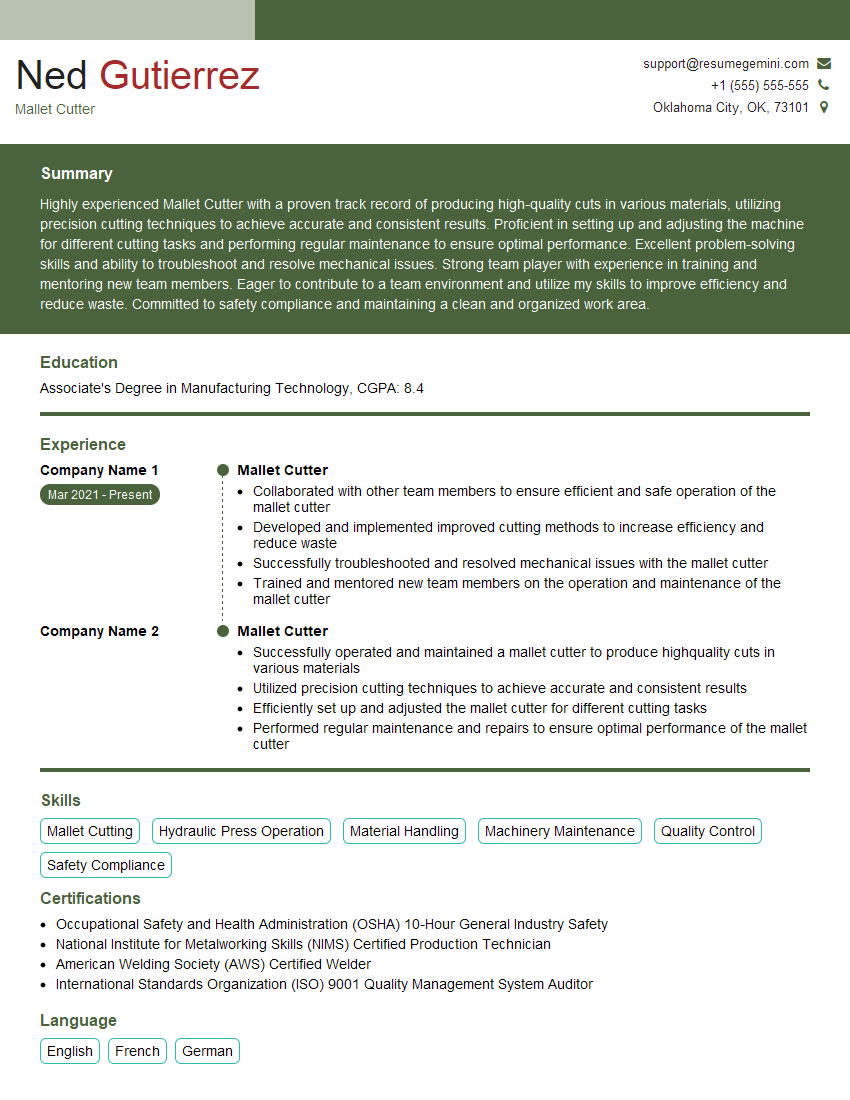

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mallet Cutter

1. What are the different types of mallets and their uses?

- Soft-faced mallets: Made of rubber, plastic, or leather, these are used for applications where minimal damage or impact is required, such as assembling furniture or tapping delicate materials.

- Hard-faced mallets: Made of metal or hardened plastic, these are used for heavier tasks like breaking concrete or driving nails.

- Specialty mallets: Designed for specific tasks, such as dead-blow mallets for reducing rebound, sledgehammers for heavy demolition, and joiners’ mallets for woodworking.

2. How do you choose the right mallet for a specific task?

- Material: Consider the hardness of the material being struck and the desired impact force.

- Size and weight: Mallet size and weight should be appropriate for the task and provide comfortable handling.

- Shape: Different mallet shapes, such as rounded or square, can affect the impact area and precision.

3. What are the safety precautions to consider when using mallets?

- Wear protective gear: Gloves to protect hands and safety glasses to prevent flying debris.

- Inspect the mallet: Check for damage or loose parts before use.

- Secure the workpiece: Clamp or stabilize the material being struck to prevent movement.

- Strike accurately: Aim for the intended target and avoid glancing blows.

4. How do you maintain a mallet for optimal performance?

- Clean and inspect: Regularly remove dirt and debris from the mallet head and handle.

- Tighten handle: Ensure the handle is securely attached to the head.

- Replace worn parts: If the head or handle becomes damaged, replace them promptly.

5. What are some tips for using a mallet effectively?

- Use the correct stance: Stand with feet apart and knees slightly bent for stability.

- Grip the handle firmly: Hold the mallet near the bottom of the handle for maximum control.

- Swing with precision: Aim for the target and strike with a smooth, controlled motion.

- Follow through: Continue the swing after impact to avoid glancing blows.

6. How do you handle a jammed or stuck mallet head?

- Lubricate the handle: Apply a penetrating oil or lubricant to the handle-head joint.

- Use a drift tool: Tap a drift tool (e.g., punch) into the hole in the mallet head to loosen it.

- Heat the head: If possible, heat the mallet head with a torch or heat gun to expand the metal.

- Remove with pliers: Grip the mallet head with pliers and gently twist to remove it from the handle.

7. How do you prevent mallet bounce-back?

- Use a dead-blow mallet: These mallets have a weighted head filled with sand or lead, reducing rebound.

- Grip the mallet firmly: Keep a tight grip on the handle to absorb some of the impact energy.

- Strike with a glancing blow: Angle the mallet slightly to avoid direct impact and minimize bounce-back.

8. What are some common mistakes to avoid when using a mallet?

- Using the wrong mallet: Choosing a mallet with inappropriate hardness or size for the task.

- Striking with excessive force: Causing damage to the workpiece or mallet.

- Neglecting safety: Not wearing protective gear or mishandling the mallet.

9. What are some advanced techniques for using a mallet?

- Compound striking: Alternating between light and heavy blows to increase impact force.

- Precision striking: Using the edge of the mallet head for controlled, precise strikes.

- Repetitive striking: Striking the same spot multiple times with a consistent rhythm for uniform results.

10. Describe your experience using mallets in practical applications.

- Assembling furniture: Used a soft-faced mallet to gently tap parts together without damaging them.

- Breaking concrete: Employed a hard-faced mallet to break up old concrete slabs for replacement.

- Driving nails: Used a joiners’ mallet to drive nails into wood accurately and securely.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mallet Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mallet Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mallet cutters are responsible for operating mallet cutting machines to cut and shape sheet metal into various shapes and sizes.

1. Machine Operation

Operate and maintain mallet cutting machines, ensuring they are in good working order.

- Set up and adjust machines according to specifications.

- Load and unload metal sheets onto the machine.

- Operate the machine to cut and shape metal sheets.

2. Quality Control

Inspect cut metal sheets to ensure they meet quality standards.

- Check for accuracy and precision in cutting.

- Identify and correct any defects or imperfections.

- Maintain accurate records of inspection results.

3. Safety Compliance

Follow all safety protocols and procedures.

- Wear appropriate safety gear, including gloves and eye protection.

- Operate machines in a safe and responsible manner.

- Report any safety hazards or concerns immediately.

4. Maintenance and Troubleshooting

Perform basic machine maintenance and troubleshooting.

- Clean and lubricate machines regularly.

- Diagnose and resolve minor machine malfunctions.

- Report any major issues to supervisors for further assistance.

Interview Tips

To ace your Mallet Cutter interview, it’s essential to prepare thoroughly. Here are some key tips to help you stand out:

1. Research the Company and Industry

Research the company’s website, social media, and industry news to gain insights into their operations, culture, and current trends.

- Identify the company’s values and mission statement.

- Learn about the industry’s best practices and technological advancements.

2. Practice Common Interview Questions

Prepare for common interview questions related to your skills, experience, and qualifications.

- Examples: “Tell me about your experience operating mallet cutting machines.” “How do you ensure the accuracy of your cuts?”

- Practice answering these questions concisely and confidently.

3. Highlight Relevant Skills and Experience

Tailor your resume and cover letter to the specific requirements of the job description.

- Quantify your accomplishments with specific metrics and results.

- Emphasize your proficiency in operating mallet cutting machines and your attention to detail.

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview demonstrates your interest and engagement.

- Examples: “What are the company’s current challenges and opportunities?” “How do you measure the performance of mallet cutters?”

- Avoid asking generic or personal questions.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Mallet Cutter role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.