Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Mold Filler interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Mold Filler so you can tailor your answers to impress potential employers.

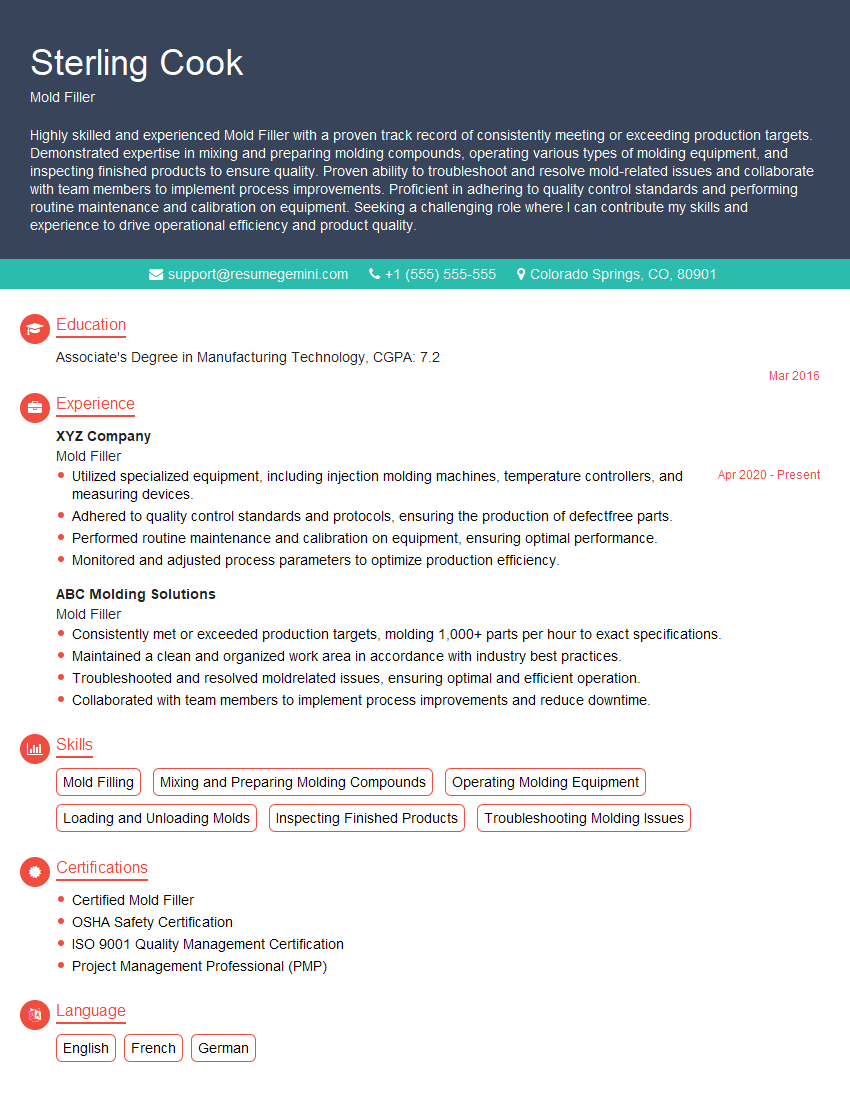

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mold Filler

1. What is the typical process involved in mold filling?

In the mold filling process, molten plastic is injected into the mold cavity under high pressure, filling the cavity and forming the desired part.

- Preheating: The mold is preheated to a specific temperature to ensure the plastic flows smoothly and fills the cavity properly.

- Injection: Molten plastic is injected into the mold cavity using an injection molding machine.

- Packing and Holding: Once the cavity is filled, pressure is maintained to pack the plastic and compensate for shrinkage.

- Cooling: The mold is cooled to solidify the plastic and allow it to take the shape of the cavity.

- Ejection: The finished part is ejected from the mold using ejector pins or other mechanisms.

2. Explain the different types of mold filling defects and how to prevent them?

Short Shot

- Causes: Insufficient plastic volume, low injection pressure, or incorrect mold temperature.

- Prevention: Increase injection pressure, check mold temperature settings, and ensure proper material volume.

Flash

- Causes: Excessive mold pressure, worn mold components, or incorrect mold alignment.

- Prevention: Adjust mold pressure settings, inspect mold components regularly, and ensure proper mold alignment.

Sink Marks

- Causes: Insufficient packing pressure, thick part sections, or slow cooling rates.

- Prevention: Increase packing pressure, redesign part geometry, or adjust cooling conditions.

3. What are the key parameters to consider when setting up the injection molding machine for mold filling?

- Injection Pressure: Determines the force applied to inject the plastic into the mold.

- Injection Speed: Controls the rate at which the plastic is injected into the mold.

- Packing Pressure: Maintains pressure on the plastic after the mold is filled to compensate for shrinkage.

- Mold Temperature: Affects the flowability of the plastic and the cooling rate of the part.

- Cycle Time: Optimizing cycle time involves balancing injection, packing, and cooling times to produce parts efficiently.

4. How do you troubleshoot common mold filling issues?

- Short Shot: Check injection pressure, material volume, and mold temperature.

- Flash: Inspect mold components for wear, adjust mold pressure, and ensure proper mold alignment.

- Sink Marks: Increase packing pressure, redesign part geometry, or adjust cooling conditions.

- Bubbles: Check material moisture content, vacuum degas the material, or adjust injection speed.

- Flow Marks: Optimize injection and packing parameters, use flow simulations to identify potential flow issues.

5. What are the different types of mold filling simulation software and how can they be used?

- Moldflow: Widely used software for simulating plastic flow, predicting defects, and optimizing molding parameters.

- Simpoe: Easy-to-use software for simulating mold filling, cooling, and warpage.

- Ansys Fluent: Advanced simulation software used for complex fluid flow and heat transfer analysis.

- SolidWorks Plastics: Integrated simulation software within SolidWorks for simulating plastic part performance.

6. Describe the different methods for degassing plastic materials before injection molding?

- Vacuum Degassing: Placing the material in a vacuum chamber to remove gases.

- Mechanical Degassing: Using a mixing screw or extruder to shear and remove gases.

- Sonic Degassing: Using ultrasonic vibrations to break down and remove gases.

- Chemical Degassing: Adding chemical agents to react with and remove gases.

7. What are the best practices for maintaining mold filling equipment?

- Regular Inspections: Inspect injection molding machines, molds, and auxiliary equipment for wear and damage.

- Preventative Maintenance: Schedule routine maintenance tasks to prevent breakdowns and ensure optimal performance.

- Calibration and Certification: Calibrate and certify equipment to ensure it meets specifications and produces consistent results.

- Training: Train operators on proper equipment operation and maintenance to prevent misuse and ensure safety.

- Documentation: Maintain detailed records of maintenance activities, repairs, and calibrations for traceability and reference.

8. Explain the role of injection mold design in achieving optimal mold filling?

- Gate Design: Optimizing gate size, location, and type to facilitate proper flow and prevent defects.

- Runner System: Designing runner channels to ensure balanced flow and minimize pressure drop.

- Part Geometry: Considering part geometry to avoid thick sections, sharp corners, and potential flow restrictions.

- Venting: Incorporating vents to release trapped air and gases during mold filling.

9. Discuss the importance of material selection for mold filling?

- Flowability: Selecting materials with good flow properties to ensure they can fill complex mold cavities.

- Viscosity: Considering material viscosity to adjust injection parameters and optimize mold filling.

- Shrinkage Rate: Accounting for material shrinkage to prevent sink marks and dimensional inaccuracies.

- Thermal Properties: Understanding thermal conductivity and specific heat capacity to optimize cooling and prevent warping.

10. How do you stay up-to-date with the latest advancements in mold filling technology?

- Industry Events and Conferences: Attending industry events to learn about new technologies and connect with experts.

- Trade Journals and Magazines: Reading industry publications to stay informed about research and development.

- Online Resources: Utilizing websites, forums, and social media to access technical articles and case studies.

- Continuing Education Courses: Participating in seminars and workshops to enhance knowledge and skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mold Filler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mold Filler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mold Fillers are responsible for filling molds with molten metal to create castings. They work in foundries and machine shops and must have a strong understanding of metallurgy and metalworking. The key job responsibilities of a Mold Filler include:

1. Mold Preparation

Mold Fillers must prepare molds by cleaning them, applying parting agents, and setting cores and inserts.

2. Mold Filling

Mold Fillers must fill molds with molten metal using ladles or pouring devices.

3. Casting Inspection and Finishing

Mold Fillers must inspect castings for defects and finish them by removing excess metal, grinding, and polishing.

4. Equipment Maintenance

Mold Fillers must maintain equipment, including ladles, pouring devices, and molds.

5. Safety

Mold Fillers must follow safety procedures to prevent accidents.

Interview Tips

To ace an interview for a Mold Filler position, candidates should be prepared to discuss their experience and knowledge in the following areas:

1. Metallurgy and Metalworking

Candidates should be familiar with different types of metals, their properties, and how they are worked.

2. Molding and Casting Processes

Candidates should be familiar with different types of molds, how they are made, and how castings are produced.

3. Equipment and Safety

Candidates should be familiar with the equipment used in foundries and machine shops and should be aware of safety procedures.

4. Problem Solving

Mold Fillers often encounter problems, such as defects in castings. Candidates should be able to demonstrate their problem-solving skills.

5. Communication and Teamwork

Mold Fillers work in teams and must be able to communicate effectively with other team members.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Mold Filler, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Mold Filler positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.