Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Paper Box Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

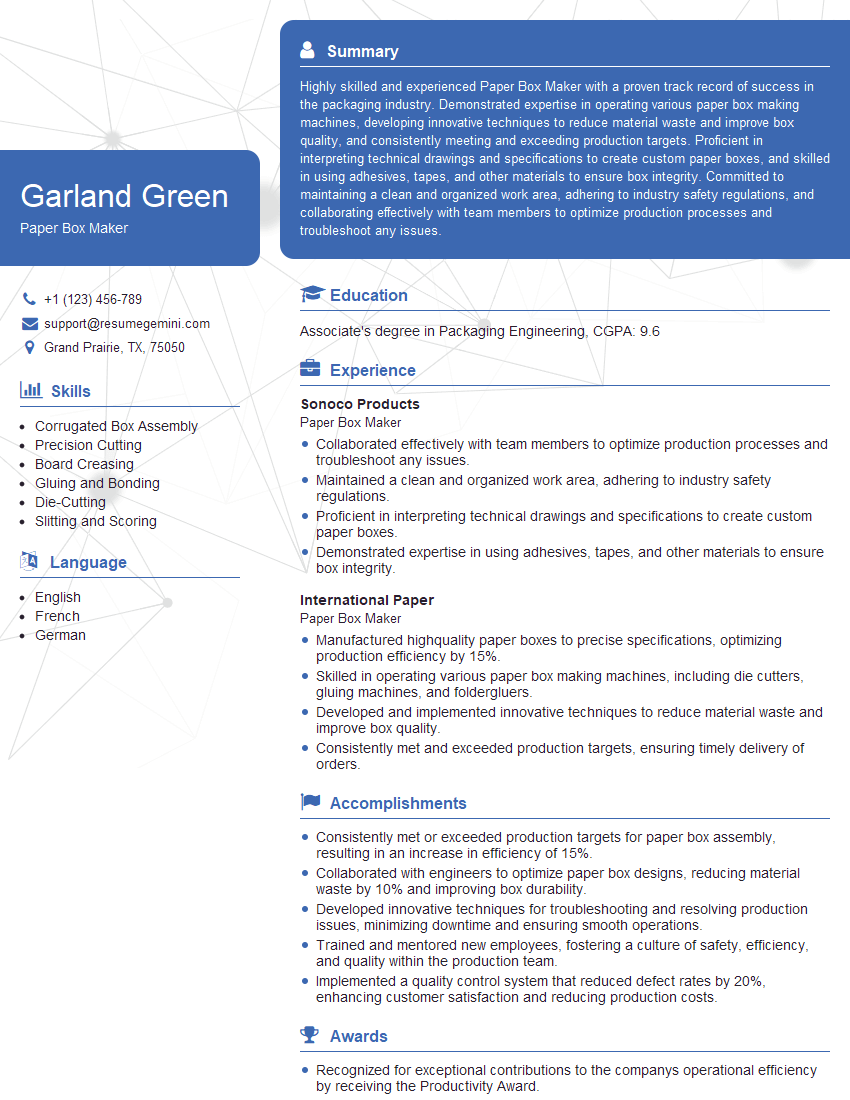

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Paper Box Maker

1. What are the different types of paper used in paper box making?

During my time at [Company], I worked with a wide range of paper types, including:

- Corrugated cardboard: A durable and versatile material used for shipping boxes, packaging, and displays.

- Kraft paper: A strong and lightweight paper often used for grocery bags, envelopes, and wrapping paper.

- Chipboard: A thick and sturdy paper used for book covers, boxes, and other products requiring rigidity.

- Art paper: A high-quality paper with a smooth surface, ideal for printing and packaging luxury items.

- Specialty papers: I have experience handling various specialty papers, such as coated, laminated, and waterproof papers, to meet specific customer requirements.

2. Describe the process of designing and creating a paper box.

Planning and Design

- Understand customer requirements and product specifications.

- Develop design concepts, considering factors like size, shape, and functionality.

- Create technical drawings and specifications for production.

Production

- Select appropriate paper materials and adhesives.

- Set up and operate machinery for cutting, creasing, and gluing.

- Maintain quality control throughout the production process.

Finishing and Assembly

- Apply any additional features, such as handles, windows, or printing.

- Assemble and inspect finished boxes to ensure they meet specifications.

- Package and prepare boxes for delivery.

3. How do you ensure the quality of your paper boxes?

Quality assurance is paramount to me, and I implement the following measures:

- Raw Material Inspection: I inspect incoming paper and adhesives for defects or inconsistencies.

- In-Process Checks: I monitor production processes continuously, checking dimensions, glue adhesion, and overall appearance.

- Finished Product Inspection: I conduct thorough inspections of finished boxes, verifying adherence to specifications and customer requirements.

- Regular Equipment Maintenance: I ensure that all machinery is properly calibrated and maintained to minimize production errors.

- Customer Feedback: I actively seek feedback from customers and use it to identify areas for improvement in quality control processes.

4. What are the different printing techniques used for paper boxes?

- Flexography: A widely used technique that uses flexible printing plates to transfer ink to the paper surface.

- Offset Lithography: A high-quality printing method that involves transferring ink from a metal plate to a rubber roller and then to the paper.

- Digital Printing: A modern technology that prints directly onto the paper using digital files, offering faster turnaround times and variable data printing capabilities.

- Screen Printing: A technique that uses a mesh screen to transfer ink onto the paper, creating bold and vibrant prints.

- Hot Foil Stamping: A process that uses heat and pressure to apply metallic foil to the paper, creating a luxurious and eye-catching effect.

5. How do you handle complex box designs and intricate cutting?

Handling complex designs requires precision and attention to detail:

- Design Understanding: I carefully analyze design specifications and identify potential challenges.

- Machine Setup: I adjust machinery settings to ensure accurate cutting and creasing based on design requirements.

- Die-Cutting Expertise: I have experience with various die-cutting machines and can handle intricate cuts and shapes with precision.

- Manual Intervention: For highly detailed or delicate cuts, I employ manual techniques to achieve the desired results.

- Quality Control: I conduct thorough inspections throughout the process to ensure the final product meets design expectations.

6. How do you optimize production efficiency for different box sizes and quantities?

- Scheduling and Planning: I plan production schedules to maximize machine utilization and minimize downtime.

- Batching Orders: I group similar orders together to reduce setup times and increase productivity.

- Equipment Selection: I choose the most appropriate machines for different box sizes and quantities, considering factors like speed, accuracy, and cost.

- Process Improvements: I continuously identify and implement process improvements to reduce waste, streamline operations, and enhance efficiency.

- Employee Training: I train operators to work efficiently and effectively, ensuring consistent quality and productivity.

7. Describe your experience with different types of adhesive and their applications in paper box making.

I have worked with various adhesives to meet specific bonding requirements:

- Water-Based Adhesives: I use water-based adhesives for general box assembly, providing a strong and cost-effective bond.

- Hot Melt Adhesives: I apply hot melt adhesives for instant bonding, ideal for high-speed production lines.

- Pressure-Sensitive Adhesives: I utilize pressure-sensitive adhesives for applications where instant tack is required, such as labels or self-sealing boxes.

- Specialty Adhesives: I have experience with specialty adhesives designed for specific materials or applications, such as food-grade or waterproof adhesives.

- Adhesive Selection: I possess the knowledge and experience to select the most suitable adhesive based on paper type, box design, and environmental conditions.

8. How do you troubleshoot common problems encountered during paper box production?

Troubleshooting is crucial to ensure smooth production:

- Creasing Issues: I analyze creasing blade sharpness, roller pressure, and paper grain to resolve creasing problems.

- Adhesive Failure: I check adhesive type, application method, and drying time to identify and rectify adhesive issues.

- Paper Defects: I inspect paper for tears, wrinkles, or moisture content that may affect box quality.

- Machine Malfunctions: I diagnose and repair common machine malfunctions, such as cutting blade dullness or conveyor belt misalignment.

- Process Optimization: I continuously assess production processes to identify and address inefficiencies or bottlenecks.

9. How do you stay updated with the latest advancements in paper box making technology?

- Industry Events: I attend trade shows and conferences to learn about new technologies and innovations.

- Technical Publications: I subscribe to industry magazines and journals to stay informed about the latest advancements.

- Online Resources: I utilize online forums and websites to connect with other professionals and exchange knowledge.

- Company Training: I participate in company-sponsored training programs to enhance my skills and learn about new technologies.

- Research and Development: I actively seek opportunities to collaborate with engineers and designers to explore cutting-edge solutions.

10. How do you ensure the safety of your team and maintain a positive work environment in the paper box making facility?

- Safety Compliance: I ensure adherence to all safety regulations and guidelines within the facility.

- Regular Training: I conduct safety training sessions to educate employees on potential hazards and safe work practices.

- Hazard Identification: I actively identify and mitigate potential safety risks in the workplace.

- Team Communication: I foster open communication and encourage employees to report any safety concerns or incidents.

- Positive Workplace: I promote a positive and inclusive work environment that values teamwork, respect, and employee well-being.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Paper Box Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Paper Box Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Paper Box Makers are responsible for the production and maintenance of paper boxes used for packaging and storage purposes. They work in industrial settings, such as factories and manufacturing plants, and use specialized machinery and tools to create and assemble boxes.

1. Box Production

The primary responsibility of a Paper Box Maker is to produce paper boxes according to specifications. This involves:

- Reading and interpreting blueprints and work orders to determine box dimensions and specifications

- Setting up and operating machinery to cut, crease, and fold paperboard into box shapes

- Assembling boxes using glue, tape, or other adhesives

- Inspecting finished boxes for quality and accuracy

2. Machine Operation and Maintenance

Paper Box Makers must also be able to operate and maintain the machinery used in box production. This includes:

- Understanding the principles of operation for cutting, creasing, and folding machines

- Performing routine maintenance and repairs on machinery

- Troubleshooting and resolving machine malfunctions

3. Materials Handling

Paper Box Makers are responsible for handling large quantities of paperboard and other materials used in box production. This involves:

- Loading and unloading materials from trucks and storage areas

- Moving materials around the production area

- Storing materials safely and securely

4. Quality Control

Paper Box Makers play a vital role in ensuring the quality of finished boxes. This involves:

- Inspecting boxes for defects, such as tears, creases, or misalignments

- Rejecting boxes that do not meet quality standards

- Identifying and correcting problems in the production process to improve quality

Interview Tips

Preparing for a job interview can be a daunting task, but with the right strategies, you can increase your chances of success. Here are some tips to help you ace your interview for a Paper Box Maker position:

1. Research the Company and Position

Take the time to learn about the company you are interviewing with, as well as the specific Paper Box Maker position. This will help you understand the company’s culture, values, and expectations for the role. You can research the company’s website, social media pages, and industry news articles to gather information.

2. Practice Your Answers to Common Interview Questions

There are certain interview questions that are commonly asked in Paper Box Maker interviews. By practicing your answers to these questions, you can feel more confident and prepared during the interview. Some common interview questions include:

- Tell me about your experience in paper box production.

- What are your strengths and weaknesses as a Paper Box Maker?

- Why are you interested in working for our company?

- What are your salary expectations?

3. Be Prepared to Discuss Your Technical Skills

Paper Box Makers need to have a strong understanding of the machinery and equipment used in box production. During the interview, be prepared to discuss your technical skills and experience. You may be asked questions about your ability to operate specific machines, perform maintenance, and troubleshoot problems.

4. Highlight Your Attention to Detail

Attention to detail is essential for Paper Box Makers. In your interview, emphasize your ability to inspect boxes for defects and ensure that they meet quality standards. You can provide examples of times when you have identified and corrected errors in the production process.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Paper Box Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!