Feeling lost in a sea of interview questions? Landed that dream interview for Paperboard Box Maker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Paperboard Box Maker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

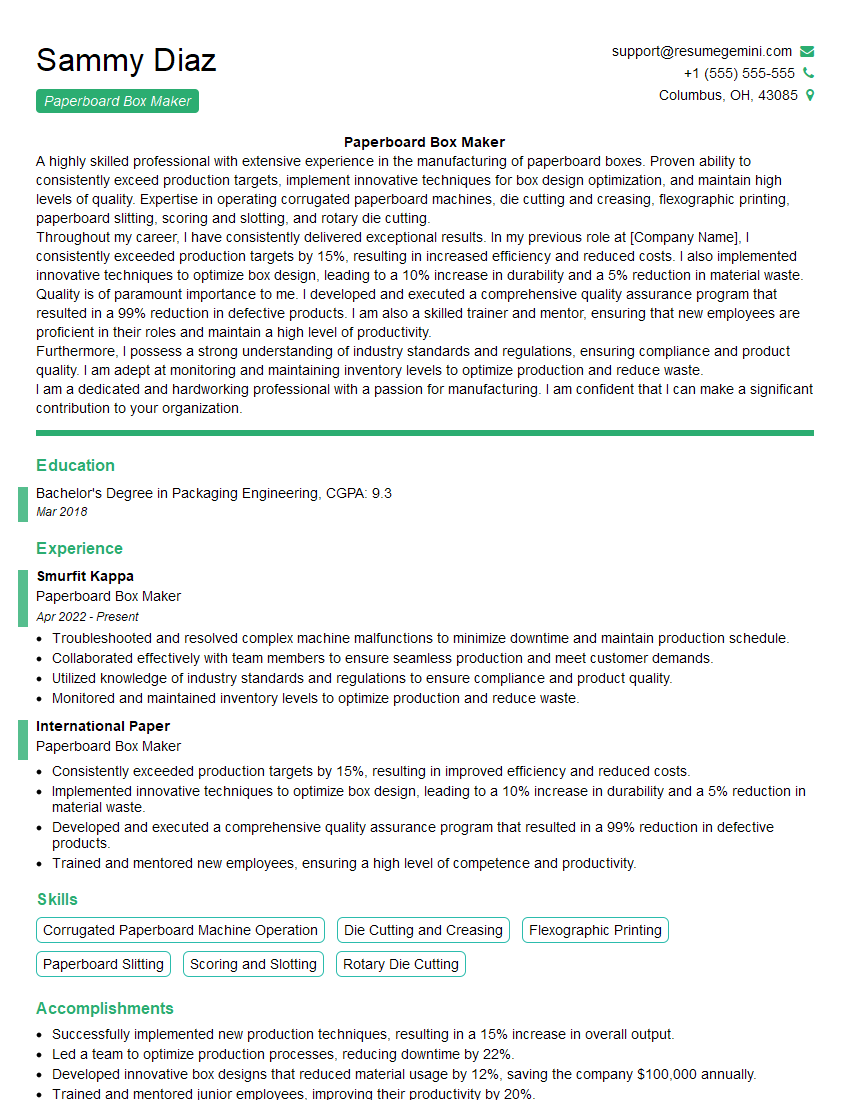

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Paperboard Box Maker

1. How to calculate the dimensions of a corrugated box?

To calculate the dimensions of a corrugated box, I use the following formula: Length = Inside Length + 2 x Thickness + 2 x Allowance; Width = Inside Width + 2 x Thickness + 2 x Allowance; Depth = Inside Depth + 2 x Thickness + Allowance. I would also consider the type of board (single, double, triple wall) and the required board grade when determining the dimensions.

2. What are the different types of paperboard used in box making?

Paperboard types:

- Kraft paperboard: made from unbleached sulfate pulp, strong and durable

- Linerboard: made from recycled paper, used as the outer layer of corrugated board

- Medium paperboard: made from recycled paper, used as the inner layer of corrugated board

- Chipboard: made from recycled paper, used for low-end packaging

3. What are the different types of corrugation?

Corrugation types:- A-flute: large and tall, offering the best cushioning

- B-flute: medium height, offering a balance of strength and cushioning

- C-flute: short and dense, providing good puncture resistance

- E-flute: very thin, ideal for lightweight packaging

4. What are the key quality control measures in box making?

Key measures:- Board quality: checking the thickness, strength, and moisture content

- Corrugation quality: ensuring proper flute height, shape, and bonding

- Printing quality: verifying clarity, color accuracy, and registration

- Die-cutting quality: inspecting for precision, cleanliness, and burr-free edges

- Assembly quality: checking for proper gluing, folding, and overall structural integrity

5. How do you optimize the efficiency of a box making machine?

Optimization steps:- Regular maintenance: performing regular cleaning, lubrication, and adjustments

- Operator training: ensuring operators are skilled and efficient in machine operation

- Material supply optimization: minimizing downtime by ensuring a consistent supply of raw materials

- Waste reduction: implementing measures to minimize waste and optimize material usage

- Process monitoring: using data collection and analysis to identify and address inefficiencies

6. What are the latest trends in paperboard box making?

Current trends:- Sustainability: using eco-friendly materials and processes

- Customizable packaging: producing boxes tailored to specific products and marketing needs

- Automation and digitization: implementing advanced technologies to improve efficiency and accuracy

- Smart packaging: incorporating features such as QR codes and RFID tags for enhanced functionality

- E-commerce packaging: designing boxes specifically optimized for online shopping and shipping

7. How do you ensure the safety of employees in a box making plant?

Safety measures:- Hazard assessment and risk management: identifying and mitigating potential hazards

- Machine guarding: installing appropriate guards and barriers around machinery

- Personal protective equipment: providing employees with appropriate safety gear

- Safety training: educating employees on safe work practices and emergency procedures

- Regular inspections and audits: conducting regular checks to ensure the workplace is safe and compliant

8. What troubleshooting skills do you have for handling common box making issues?

Troubleshooting skills:- Identifying and resolving printing quality issues (e.g., color variations, smudging)

- Diagnosing and fixing corrugation problems (e.g., flute height issues, weak bonding)

- Addressing die-cutting errors (e.g., misaligned cuts, burrs)

- Adjusting machine settings to optimize efficiency and minimize scrap

- Resolving assembly issues (e.g., gluing problems, structural defects)

9. How do you stay updated with the latest advancements in box making technology?

Knowledge update methods:- Attending industry conferences and trade shows

- Reading technical journals and publications

- Participating in online forums and communities

- Consulting with equipment manufacturers and industry experts

- Seeking opportunities for professional development and training

10. What are your strengths and weaknesses as a paperboard box maker?

Strengths:- Thorough understanding of paperboard properties and box design principles

- Proven ability to operate and troubleshoot box making machinery

- Strong attention to detail and quality control

- Excellent communication and teamwork skills

- Commitment to safety and continuous improvement

- Less experience with certain specialty box types (e.g., highly customized or complex designs)

- Limited knowledge of advanced automated box making systems

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Paperboard Box Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Paperboard Box Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Paperboard Box Makers are responsible for the production of paperboard boxes. They operate machinery to cut, fold, and glue paperboard into boxes of various sizes and shapes. The primary responsibilities of a Paperboard Box Maker include:

1. Production of Paperboard Boxes

Using machinery to cut, fold, and glue paperboard into boxes of various sizes and shapes.

2. Setting up and Maintaining Equipment

Setting up, adjusting, and maintaining machinery used in the production of paperboard boxes.

3. Quality Control

Inspecting paperboard boxes to ensure they meet quality standards.

4. Material Handling

Loading and unloading raw materials and finished goods.

5. Other Responsibilities

May also be responsible for cleaning and maintaining the work area.

Interview Tips

Preparing for an interview can be a daunting task. However, by following a few simple tips, you can increase your chances of success. Here are some interview tips and hacks to help you ace your interview for a Paperboard Box Maker position:

1. Research the Company and the Role

One of the best ways to prepare for an interview is to research the company and the role you’re applying for. This will give you a good understanding of the company’s culture, values, and goals, as well as the specific requirements of the job. You can research the company’s website, LinkedIn page, and Glassdoor reviews to learn more about the company and the role.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this role?”. It’s a good idea to practice your answers to these questions in advance so that you can deliver them confidently and concisely during the interview. You can also prepare for specific questions related to the Paperboard Box Maker role, such as “What experience do you have in operating machinery to cut, fold, and glue paperboard?” or “How do you ensure quality control in your work?”.

3. Dress Professionally and Arrive on Time

First impressions matter, so it’s important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting. You should also arrive on time for your interview. Punctuality shows that you’re respectful of the interviewer’s time and that you’re serious about the job.

4. Be Enthusiastic and Positive

It’s important to be enthusiastic and positive during your interview. This shows the interviewer that you’re excited about the opportunity and that you’re confident in your abilities. You should also be prepared to talk about your skills and experience, and how they can benefit the company. However, it’s important to be genuine in your enthusiasm. If you’re not truly interested in the role or the company, it will be difficult to convince the interviewer that you’re the right person for the job.

5. Follow Up After the Interview

After the interview, it’s important to follow up with the interviewer. This shows that you’re still interested in the role and that you’re eager to learn more about the next steps. You can follow up by sending a thank-you note or email, or by calling the interviewer to check in. In your follow-up, you can reiterate your interest in the role and thank the interviewer for their time.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Paperboard Box Maker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Paperboard Box Maker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.