Are you gearing up for a career in Piston Maker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Piston Maker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

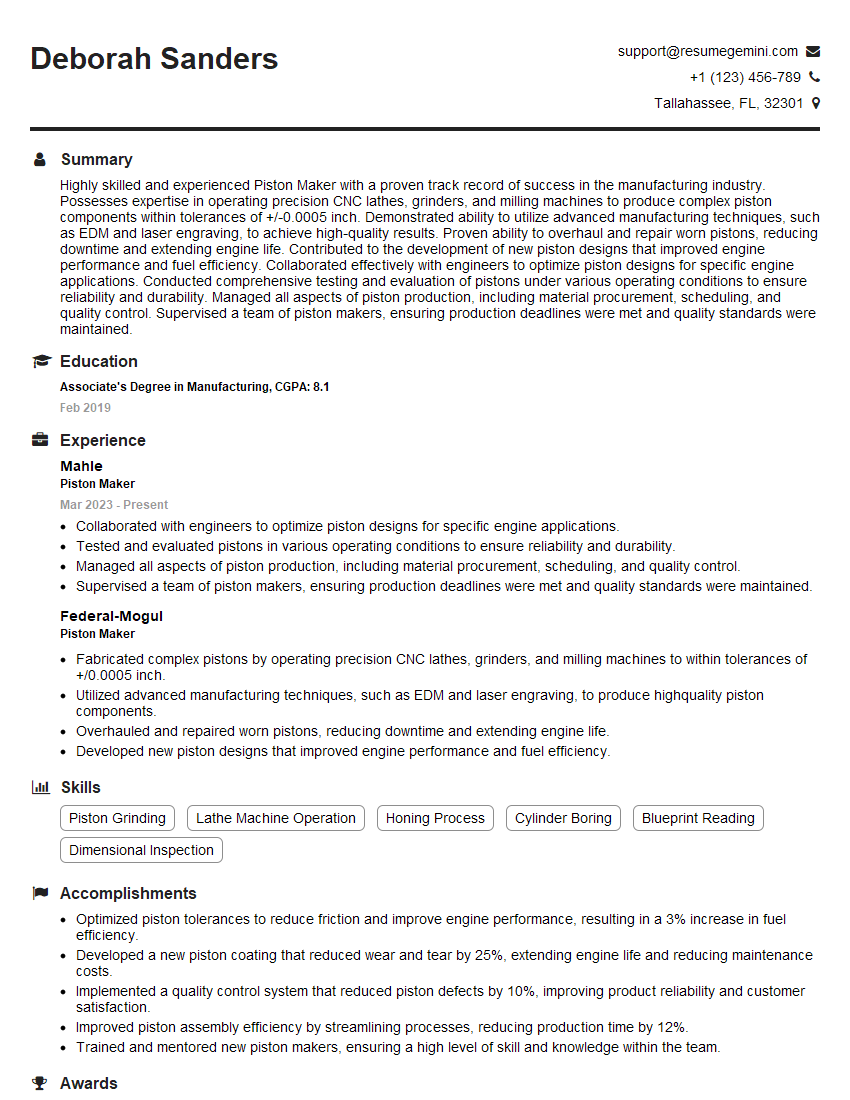

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Piston Maker

1. What are the primary materials used in piston manufacturing and their properties?

There are several primary materials used in piston manufacturing, each with its own unique properties:

- Aluminum: Lightweight, high strength-to-weight ratio, good thermal conductivity, but prone to wear and tear.

- Cast iron: Durable, wear-resistant, and heat-resistant, but heavier than aluminum.

- Steel: Strong, durable, and wear-resistant, but more expensive than aluminum and cast iron.

- Ceramic: Lightweight, durable, and heat-resistant, but expensive and brittle.

2. Explain the different types of piston rings and their functions.

Compression Rings

- Seal the combustion chamber to prevent gas leakage.

- Control oil consumption by scraping excess oil from the cylinder walls.

Oil Control Rings

- Scrape excess oil from the cylinder walls and return it to the oil pan.

- Prevent oil from entering the combustion chamber.

3. Describe the process of piston forging.

Piston forging involves heating a metal billet to a high temperature and shaping it into the desired form using a press or hammer:

- Preforming: The billet is heated and shaped into a rough preform.

- Forging: The preform is further shaped and compacted using a series of dies.

- Finishing: The forged piston is trimmed, heat-treated, and machined to final dimensions.

4. Explain the concept of piston clearance and its significance.

Piston clearance is the space between the piston and the cylinder wall. It is critical for proper engine operation:

- Too little clearance: Piston can seize or weld to the cylinder wall.

- Too much clearance: Piston can rattle and cause excessive noise and vibration.

5. Describe the different types of piston coatings and their applications.

Piston coatings can enhance piston performance and durability:

- Molybdenum disulfide (MoS2): Reduces friction and wear between piston and cylinder.

- Graphite: Improves heat transfer and reduces scuffing.

- Ceramic: Protects against wear, corrosion, and heat.

- Polymer: Enhances sealing and reduces friction.

6. Explain the importance of piston cooling and describe different cooling methods.

Piston cooling is crucial to prevent overheating and ensure engine reliability:

- Oil cooling: Oil jets spray oil on the underside of the piston to dissipate heat.

- Water cooling: Channels within the piston carry coolant to absorb heat.

- Piston crown cooling: Heat is transferred from the piston crown to the cylinder head through direct contact.

7. Describe the different factors influencing piston design and selection.

Factors to consider when designing and selecting pistons include:

- Engine type: Combustion characteristics, performance requirements.

- Materials: Strength, weight, durability, cost.

- Dimensions: Bore, stroke, compression ratio.

- Piston shape: Flat, dome, dish.

- Cooling requirements: Heat transfer capacity.

8. Explain the importance of piston balancing and its impact on engine performance.

Piston balancing ensures equal weight distribution, reducing vibrations and improving engine smoothness:

- Primary balance: Balancing the mass of the piston and connecting rod as they rotate.

- Secondary balance: Balancing forces generated by the piston reciprocating motion.

9. Describe the various quality control measures employed in piston manufacturing.

Quality control measures ensure pistons meet specifications and performance requirements:

- Dimensional inspection: Verifying dimensions, tolerances, and geometry.

- Material testing: Analyzing material properties for strength, durability, and wear resistance.

- Surface inspection: Examining for defects, scratches, and imperfections.

- Performance testing: Evaluating piston performance in simulated engine conditions.

10. Explain the emerging trends and advancements in piston manufacturing technology.

Advancements in piston manufacturing include:

- Lightweight materials: Aluminum alloys with improved strength-to-weight ratio.

- Advanced coatings: Coatings for improved friction reduction, wear resistance, and heat transfer.

- Additive manufacturing: 3D printing techniques for complex piston designs and optimization.

- Computer simulation: Modeling and simulation to optimize piston performance and durability.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Piston Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Piston Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Piston Makers, also known as Engine Piston Makers, play a vital role in the automotive industry by manufacturing and maintaining pistons, which are crucial components in engines.

1. Manufacture Pistons

Piston Makers are responsible for the production of pistons, which involves cutting, grinding, and machining raw materials to create the desired shape and dimensions.

- Operate and maintain precision machinery, such as CNC machines and lathes.

- Monitor and adjust machine settings to ensure accuracy and efficiency.

- Inspect and test finished pistons to meet quality standards.

2. Maintain and Repair Pistons

Piston Makers also perform maintenance and repair tasks to ensure the proper functioning of pistons in engines.

- Identify and diagnose piston issues, such as wear, damage, or improper fit.

- Repair or replace pistons and their components, such as rings, pins, and skirts.

- Calibrate and adjust pistons to optimize engine performance.

3. Analyze and Improve Piston Designs

Piston Makers may contribute to the design and improvement of pistons through their expertise and experience.

- Conduct research and analysis to optimize piston performance and efficiency.

- Provide feedback and suggestions on piston designs to engineers and managers.

- Implement new technologies and techniques to enhance piston production and maintenance.

4. Quality Assurance

Piston Makers are responsible for maintaining high standards of quality throughout the manufacturing and maintenance processes.

- Establish and implement quality control procedures to ensure product consistency.

- Inspect and test pistons at various stages of production to identify and correct any defects.

- Document and maintain records of quality control activities.

Interview Tips

Preparing thoroughly for an interview is crucial for any job position, but especially so for specialized roles like Piston Maker. Here are some tips to help you excel in your interview.

1. Research the Company and Position

Demonstrating your knowledge about the company and the specific Piston Maker role shows that you are genuinely interested in the opportunity. Research the company’s history, products, and industry standing. Familiarize yourself with the job description and its key responsibilities.

2. Highlight Your Technical Skills

Piston Makers are highly skilled in machining and manufacturing processes. During the interview, emphasize your proficiency in operating and maintaining precision machinery, such as CNC machines and lathes. Showcase your ability to read and interpret technical drawings, and explain how you ensure accuracy and precision in your work.

3. Provide Examples of Your Experience

Interviews are not just about answering questions but also about demonstrating your capabilities through concrete examples. Prepare specific instances where you successfully manufactured, repaired, or improved pistons. Quantify your results whenever possible to demonstrate the impact of your work.

4. Show Your Passion for the Industry

Piston Makers are typically passionate about the automotive industry and engine mechanics. Share your enthusiasm for the field and explain how your interest drives you to excel in your work. Describe any projects or personal endeavors that showcase your dedication to piston manufacturing or engine performance.

5. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows your engagement and genuine interest in the role. Prepare a few questions related to the company’s piston production processes, research and development initiatives, or career advancement opportunities. It also gives you a chance to clarify any uncertainties you may have about the position.

Next Step:

Now that you’re armed with the knowledge of Piston Maker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Piston Maker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini