Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Plywood Patcher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

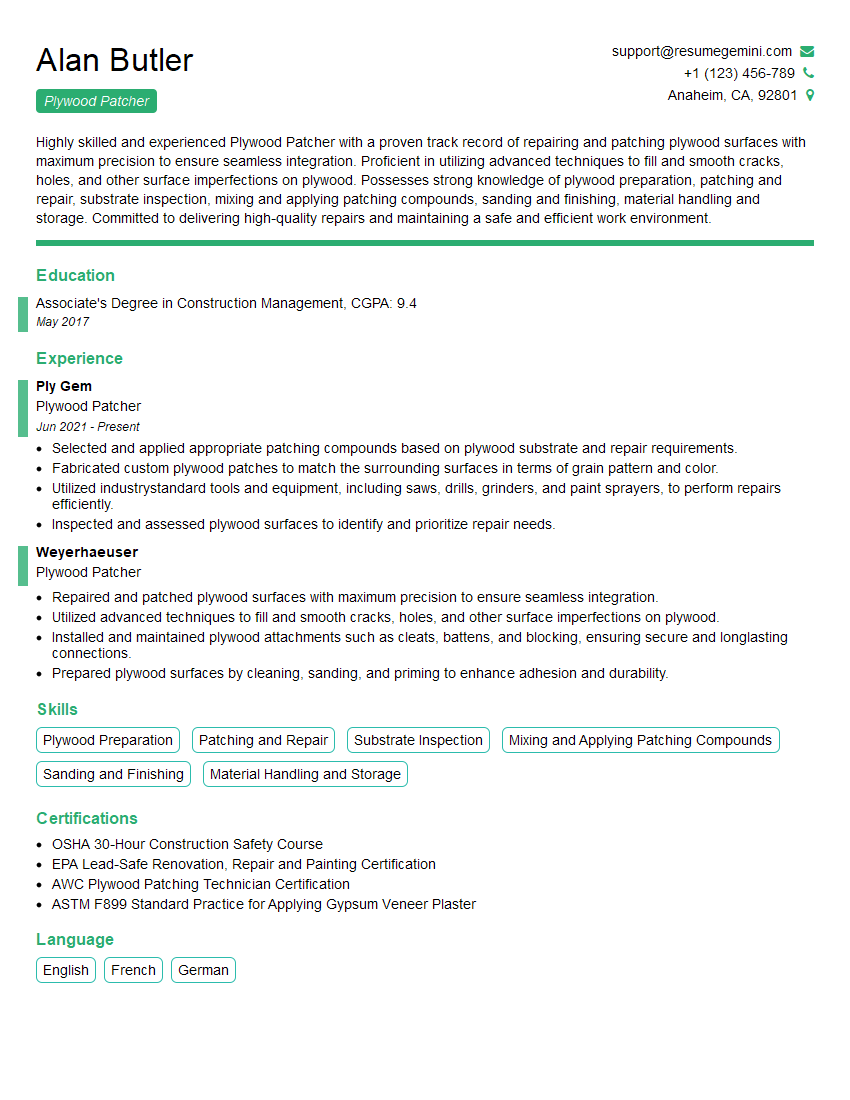

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plywood Patcher

1. What are the different types of plywood patches and when should each type be used?

- There are two main types of plywood patches: temporary and permanent.

- Temporary patches are used to cover small holes or cracks in the plywood and are typically made of a flexible material such as rubber or plastic.

- Permanent patches are used to repair larger holes or cracks in the plywood and are typically made of a more durable material such as wood or metal.

2. What are the steps involved in patching a hole in plywood?

Preparing the hole

- The first step is to prepare the hole by cleaning it out and removing any debris.

- If the hole is large, you may need to square off the edges with a chisel or utility knife.

Cutting the patch

- Once the hole is prepared, you need to cut a patch that is slightly larger than the hole.

- The patch can be cut from a scrap piece of plywood or from a new sheet of plywood.

Applying the patch

- The next step is to apply the patch to the hole.

- If the patch is made of wood, you can use wood glue to attach it to the plywood.

- If the patch is made of metal, you can use screws or nails to attach it to the plywood.

3. What are some common mistakes that people make when patching plywood?

- One common mistake is using the wrong type of patch.

- For example, using a temporary patch to repair a large hole.

- Another common mistake is not preparing the hole properly.

- This can lead to the patch not adhering properly and failing.

4. What are some tips for patching plywood successfully?

- Use the right type of patch for the job.

- Prepare the hole properly before applying the patch.

- Make sure the patch is slightly larger than the hole.

- Use the correct adhesive or fasteners to attach the patch.

5. What are the different types of tools and materials that are used for patching plywood?

Tools

- Chisel

- Hammer

- Nail gun

- Sandpaper

- Saw

- Screwdriver

Materials

- Plywood

- Wood glue

- Nails

- Screws

6. What are some safety precautions that should be taken when patching plywood?

- Wear gloves and safety glasses when using sharp tools.

- Be careful when using power tools.

- Make sure the work area is well-ventilated.

7. What are some techniques that can be used to make a plywood patch less noticeable?

- Use a patch that is the same color as the plywood.

- Sand the edges of the patch to blend it in with the surrounding plywood.

- Apply a clear finish over the patch to protect it and make it less noticeable.

8. What are some tips for patching plywood in a humid environment?

- Use a waterproof adhesive or sealant to attach the patch.

- Make sure the patch is properly sealed to prevent moisture from getting in.

- Inspect the patch regularly and repair any damage as soon as possible.

9. What are some techniques that can be used to patch plywood in a cold environment?

- Use a cold-weather adhesive or sealant to attach the patch.

- Make sure the patch is properly sealed to prevent cold air from getting in.

- Cover the patch with a tarp or other protective material to keep it warm.

10. What are some tips for patching plywood in a high-traffic area?

- Use a durable patch that can withstand heavy foot traffic.

- Make sure the patch is properly attached and sealed.

- Inspect the patch regularly and repair any damage as soon as possible.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plywood Patcher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plywood Patcher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Plywood Patcher, you will be responsible for a wide range of duties related to the repair and maintenance of plywood surfaces. Your primary focus will be on identifying and repairing any defects or damage to plywood, ensuring the structural integrity and aesthetic appeal of the material.

Key responsibilities include but are not limited to:

1. Inspect and Identify Plywood Damage

Thoroughly inspect plywood surfaces to identify any areas of damage, such as cracks, holes, dents, or delamination.

- Determine the extent and severity of the damage.

- Assess the underlying cause of the damage to prevent future issues.

2. Prepare Damaged Area for Repair

Clean and prepare damaged areas by removing any debris, loose material, or contaminants.

- Sand or grind the damaged area to smooth out any edges or irregularities.

- Apply a patching compound or adhesive to the prepared surface.

3. Patch and Repair Plywood Damage

Fill damaged areas with an appropriate patching compound or adhesive.

- Use a variety of tools and techniques to apply the patching material, such as spatulas, trowels, or brushes.

- Ensure that the repaired area is level and smooth with the surrounding surface.

4. Finish and Seal Repaired Area

Once the patch is dry, sand and smooth the repaired area to blend it seamlessly with the surrounding plywood.

- Apply a sealant or finish to protect the repaired area from further damage or moisture.

- Ensure that the finished repair is aesthetically pleasing and meets industry standards.

Interview Tips

Preparing for a Plywood Patcher interview requires a combination of technical knowledge and a professional demeanor. Here are some tips to help you ace your interview:

Before the Interview:

1. Research the Company and Position

Learn about the company’s history, values, and the specific role of a Plywood Patcher within the organization. This will demonstrate your interest and enthusiasm for the position.

- Visit the company’s website and review their mission statement and services.

- Read articles or reviews about the company to gain insights into their industry standing.

2. Practice Your Plywood Patching Skills

Refresh your knowledge and skills in plywood patching techniques. Practice identifying and repairing common types of plywood damage.

- Review industry standards and best practices for plywood repair.

- If possible, practice on scrap pieces of plywood to demonstrate your proficiency.

3. Prepare Questions for the Interviewer

Asking thoughtful questions during the interview shows that you are engaged and interested in the position. Prepare questions about the company’s expectations, growth opportunities, and the specific responsibilities of the role.

- Ask about the company’s approach to quality control and customer satisfaction.

- Inquire about the training and support provided for Plywood Patchers.

During the Interview:

4. Dress Professionally and Arrive on Time

Make a good first impression by dressing appropriately and arriving for your interview on time. This conveys respect and professionalism.

- Choose business casual attire or a uniform similar to what you would wear on the job.

- Allow ample time for travel and parking to avoid any delays.

5. Be Confident and Enthusiastic

Project confidence in your abilities and enthusiasm for the role during the interview. Maintain good eye contact and speak clearly and articulately.

- Highlight your experience and skills in plywood patching, emphasizing your attention to detail and commitment to quality.

- Express your interest in the company and the position, and explain why you are a suitable candidate.

Next Step:

Now that you’re armed with the knowledge of Plywood Patcher interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Plywood Patcher positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini