Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pot Builder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

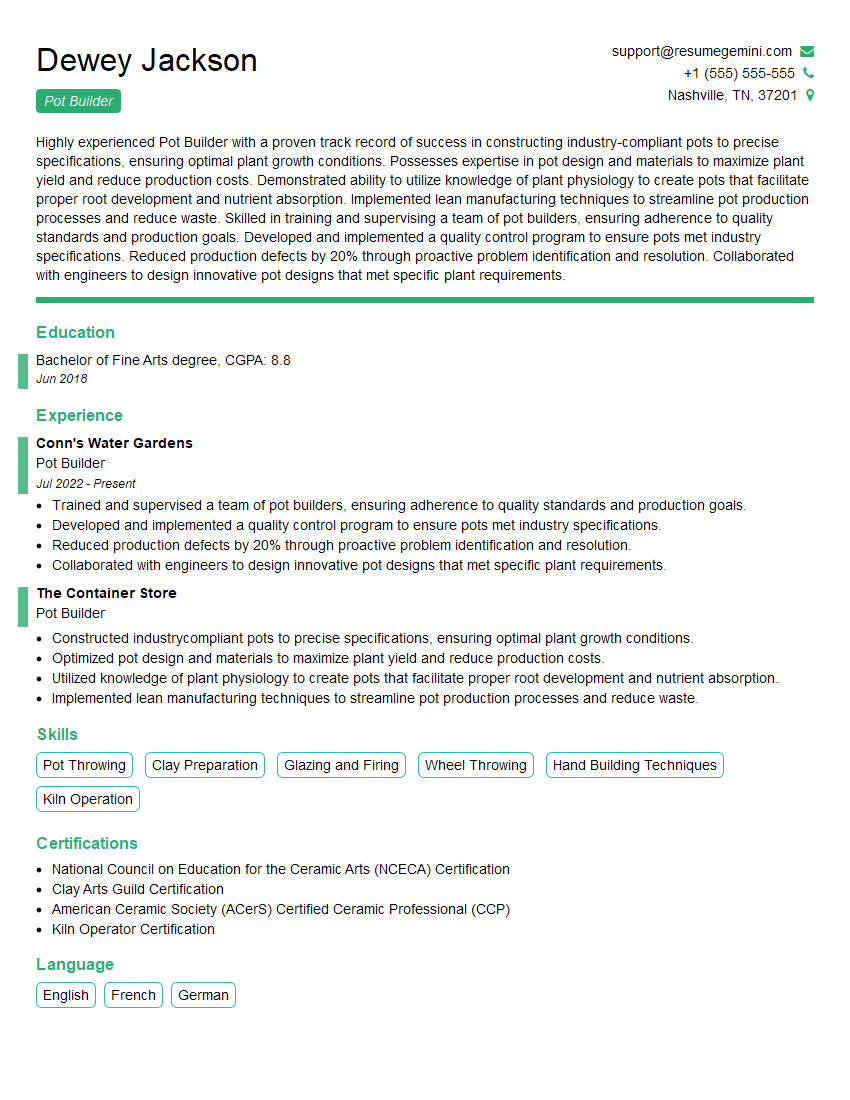

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pot Builder

1. What types of pots have you built, and what materials did you use in each case?

- Described the different types of pots I have built, such as wheel-thrown, hand-built, and slip-cast.

- Specified the materials used in each type of pot, such as clay, glazes, and oxides.

2. What are the key steps involved in the pot-building process?

Planning and Design

- Conceptualizing the pot’s form, size, and function.

- Creating sketches and templates to guide the construction.

Clay Preparation and Wedging

- Preparing the clay by mixing it with water to achieve the desired consistency.

- Wedging the clay to remove air bubbles and ensure even moisture distribution.

Forming Techniques

- Using different techniques such as wheel-throwing, hand-building, or slip-casting to shape the pot.

- Trimming and refining the pot’s form to achieve the desired shape and size.

Glazing and Firing

- Applying glazes to the pot’s surface to create color and texture.

- Firing the pot in a kiln to harden the clay and fuse the glaze.

3. What factors should be considered when choosing the right type of clay for a project?

- Purpose of the pot: functional or decorative.

- Firing temperature: the type of clay must be compatible with the kiln’s firing temperature.

- Plasticity and workability: the clay’s ability to be shaped and manipulated easily.

- Texture and color: the natural color and texture of the clay can influence the final appearance of the pot.

- Glaze compatibility: the clay’s surface must be compatible with the chosen glaze.

4. How do you ensure the even distribution of heat during firing to prevent cracking or warping?

- Proper kiln packing: arranging the pots inside the kiln with adequate space between them.

- Graduated firing: slowly increasing the temperature to allow the pots to adjust gradually.

- Use of kiln shelves: supporting the pots on kiln shelves to prevent direct contact with the kiln floor.

- Monitoring temperature: using a pyrometer or kiln controller to ensure accurate temperature readings.

- Annealing: slowly cooling the kiln after firing to relieve stress in the clay.

5. Describe the different types of glazes and their properties.

Clear Glazes

- Transparent glazes that allow the natural color of the clay to show through.

- Glossy or matte finish depending on the glaze composition.

Opaques Glazes

- Non-transparent glazes that create a solid color or pattern on the pot.

- Can be used to achieve a wide range of colors and textures.

Crystalline Glazes

- Glazes that develop crystals during firing, creating a unique and textured surface.

- Require specific firing schedules to achieve the desired crystal growth.

6. How do you troubleshoot common problems that arise during the pot-building process?

Cracking

- Insufficient drying time before firing.

- Uneven heat distribution during firing.

- Improper clay preparation or wedging.

Warping

- Uneven thickness of the pot walls.

- Insufficient support during drying.

- Improper kiln packing or firing schedule.

Glaze Defects

- Improper glaze application or firing temperature.

- Incompatibility between the clay and glaze.

- Contamination of the glaze with dust or debris.

7. How do you maintain and clean your equipment, such as the pottery wheel and kiln?

- Regular cleaning of the pottery wheel head and bat pins to prevent clay buildup.

- Lubrication of moving parts to ensure smooth operation.

- Cleaning the kiln interior after each firing to remove ash and debris.

- Regular inspection and maintenance of the kiln elements and thermocouple.

8. What safety precautions do you take when working in the pottery studio?

- Wearing appropriate clothing and footwear, including a pottery apron and closed-toe shoes.

- Using sharp tools with care and keeping them in good condition.

- Handling heavy equipment, such as the kiln, with proper lifting techniques.

- Maintaining a clean and organized work area.

- Being aware of potential hazards, such as electrical cords and hot surfaces.

9. How do you stay updated with the latest trends and techniques in the field of ceramics?

- Attending workshops and conferences.

- Reading books and articles.

- Visiting museums and galleries.

- Networking with other potters and artists.

- Experimenting with different materials and techniques.

10. What is your approach to problem-solving when faced with challenges during the pot-building process?

- Identify the problem and its potential causes.

- Research and explore different solutions.

- Test and evaluate the potential solutions.

- Make adjustments based on the results of the tests.

- Implement the most effective solution and monitor its impact.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pot Builder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pot Builder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pot builders play a crucial role in the manufacturing of fiberglass products, shaping and reinforcing the raw materials to create durable and effective components. Their key responsibilities include:

1. Mold Preparation and Material Handling

Inspecting and preparing molds to ensure they are clean and free of defects.

- Applying mold release agents to prevent finished products from sticking.

- Mixing and measuring fiberglass resins, gel coats, and other materials according to specifications.

2. Product Fabrication

Applying fiberglass layers to molds using brushes, rollers, or sprayers.

- Compacting and smoothing fiberglass layers to achieve uniform thickness and strength.

- Trimming and sanding finished products to precise dimensions.

3. Quality Control

Inspecting finished products for defects and ensuring they meet quality standards.

- Performing leak tests, strength tests, or other required inspections.

- Identifying and correcting any flaws before products are released.

4. Equipment Maintenance

Maintaining and cleaning equipment used in the production process.

- Checking and calibrating spraying equipment, mixers, or other machinery.

- Replacing worn or damaged components to ensure efficient operation.

5. Environmental Health and Safety

Following all safety protocols and regulations.

- Wearing protective gear and handling hazardous materials properly.

- Maintaining a clean and organized work environment.

Interview Tips

To ace the interview for a Pot Builder position, it is essential to prepare and showcase your skills and experience effectively.

1. Research the Company and Role

Before the interview, thoroughly research the company and the specific role you are applying for. This demonstrates your interest and enthusiasm.

- Visit the company’s website to understand their products, services, and culture.

- Review the job description and identify the key responsibilities and qualifications.

2. Practice Common Interview Questions

There are a few common interview questions that you can anticipate and prepare for, such as:

- “Tell me about yourself and your experience in pot building.”

- “Describe your knowledge of fiberglass materials and their applications.”

- “How do you ensure the quality of your finished products?”

- “What are your strengths and weaknesses as a Pot Builder?”

- “Why are you interested in working for this company?”

3. Showcase Your Skills and Experience

During the interview, highlight your relevant skills and experience. Quantify your accomplishments whenever possible.

- Mention the types of fiberglass products you have worked on and the production techniques you are proficient in.

- Provide examples of how you have consistently met or exceeded quality standards.

- If you have any experience in mold making or composite fabrication, be sure to mention it.

4. Be Enthusiastic and Positive

Throughout the interview, maintain a positive and enthusiastic attitude. This will show the interviewer that you are passionate about your work.

- Speak confidently about your skills and experience.

- Ask thoughtful questions about the company and the role to demonstrate your interest.

- Express your eagerness to contribute to the team and make a positive impact.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Pot Builder role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.