Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Primer Assembler interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Primer Assembler so you can tailor your answers to impress potential employers.

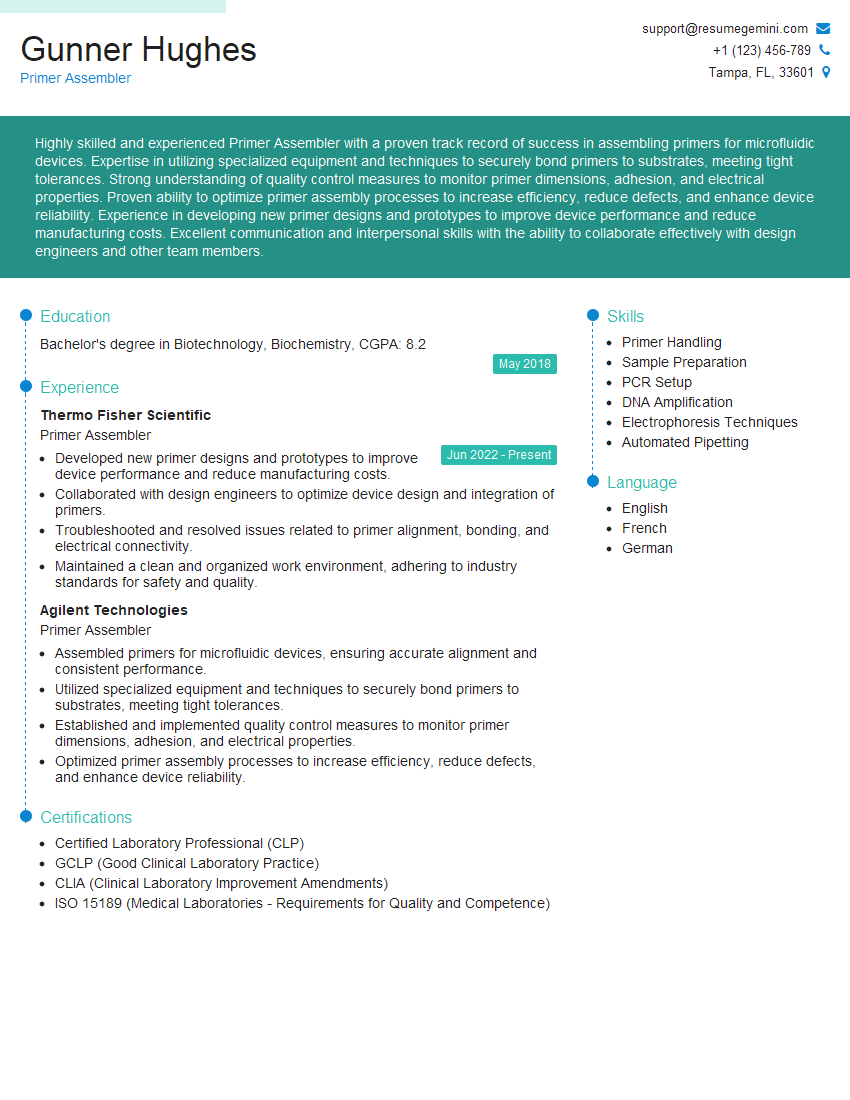

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Primer Assembler

1. What are the key responsibilities of a Primer Assembler?

As a Primer Assembler, my primary responsibilities include:

- Assembling and installing primers, detonators, and booster assemblies.

- Inspecting and testing components to ensure they meet specifications.

- Maintaining and troubleshooting equipment.

- Adhering to safety protocols and regulations.

2. Describe the different types of primers used in ammunition.

Impact-Sensitive Primers

- Sensitive to mechanical shock

- Used in firearms, shotgun shells, and some types of detonators

Electric Primers

- Triggered by an electrical current

- Used in military applications, pyrotechnics, and some commercial products

Pyrotechnic Primers

- Use a pyrotechnic composition to initiate detonation

- Found in fireworks, flares, and other pyrotechnic devices

3. What is the purpose of a detonator?

A detonator is used to create a high-order explosion that initiates the main explosive charge. It does this by rapidly converting a low-velocity detonation into a high-velocity detonation.

4. What are the safety precautions that must be taken when working with primers and detonators?

Handling primers and detonators requires strict adherence to safety precautions, including:

- Always wearing appropriate personal protective equipment (PPE)

- Working in a designated and controlled environment

- Using proper tools and equipment

- Following all established safety protocols and procedures

5. What is the difference between a primer and a detonator?

- Primer:

- Initiates the secondary explosive in a detonator

- Typically uses a low-energy impact to trigger an explosive reaction

- Detonator:

- Uses a primer to produce a high-order detonation

- Initiates the main explosive charge in ammunition, explosives, and other devices

6. What are the different methods of primer assembly?

- Manual Assembly:

- Using hand tools and presses to assemble primers

- Automated Assembly:

- Using machines to assemble primers in a automated and efficient manner

7. What are the challenges involved in primer assembly?

- Precision and Accuracy:

- Primers require precise assembly to ensure consistent performance and safety

- Safety:

- Primers are sensitive and can be dangerous if handled improperly

- Efficiency:

- Primer assembly needs to be efficient to meet production demands

8. What are the quality control procedures for primer assembly?

- Visual Inspection:

- Inspecting primers for defects and damage

- Dimensional Measurement:

- Verifying the dimensions of primers meet specifications

- Performance Testing:

- Conducting tests to ensure primers function correctly

9. What is the role of automation in primer assembly?

Automation plays a vital role in primer assembly by:

- Improving Efficiency:

- Machines can assemble primers faster and more consistently than manual labor

- Reducing Errors:

- Automation eliminates human errors and ensures precision

- Enhancing Safety:

- Machines can handle primers more safely, reducing the risk of accidents

10. What are the latest advancements in primer assembly technology?

Some of the latest advancements in primer assembly technology include:

- Laser Marking:

- Using lasers to mark primers with unique identifiers for traceability and quality control

- Computer-Controlled Assembly:

- Using computer-controlled machines to precisely assemble primers

- Advanced Inspection Systems:

- Employing advanced inspection systems to detect defects and ensure quality

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Primer Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Primer Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Primer Assemblers are craftsmen who work in manufacturing plants that produce small, precise parts for a variety of industries. They are responsible for assembling and inspecting primers, which are essential components for detonating explosives.

1. Assembling Primers

The primary responsibility of a Primer Assembler is to assemble primers. This involves fitting various components together, such as the primer cup, anvil, and explosive compound. The assembler must ensure that the components are assembled correctly and that the primer meets the required specifications.

- Assemble primers according to engineering drawings and specifications.

- Use hand tools and equipment to assemble primer components, such as primer cups, anvils, and explosive compounds.

- Inspect primers to ensure they meet quality standards.

2. Maintaining Equipment

Primer Assemblers are also responsible for maintaining their equipment. This includes cleaning and lubricating machines, and performing minor repairs. They must also ensure that their equipment is calibrated correctly and that it is operating safely.

- Clean and lubricate machines and equipment.

- Perform minor repairs on equipment.

- Calibrate equipment to ensure accuracy.

3. Following Safety Procedures

Primer Assemblers work with potentially hazardous materials, so they must follow safety procedures at all times. This includes wearing proper protective gear and following established protocols for handling and storing explosives.

- Follow all safety procedures.

- Wear proper protective gear.

- Handle and store explosives according to established protocols.

4. Troubleshooting Problems

Primer Assemblers may encounter problems during the assembly process. They must be able to troubleshoot these problems and find solutions. This may involve consulting with engineers or other experts.

- Troubleshoot problems during the assembly process.

- Consult with engineers or other experts to find solutions.

Interview Tips

Preparing for an interview for a Primer Assembler position can be daunting, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace the interview:

1. Research the Company

Before the interview, take some time to research the company. This will help you understand their business and culture, which will make you more prepared to answer questions about why you want to work for them.

- Visit the company’s website.

- Read news articles about the company.

- Talk to people who work for the company.

2. Practice Answering Common Interview Questions

There are some common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. Practice answering these questions in advance so that you can deliver your answers confidently and concisely.

- Prepare answers to common interview questions.

- Practice answering questions out loud.

- Ask a friend or family member to help you with your practice.

3. Highlight Your Skills and Experience

Be sure to highlight your skills and experience that are relevant to the position. For example, if you have experience working with explosives or assembling small parts, be sure to mention this in your interview.

- Tailor your resume and cover letter to the position.

- Highlight your skills and experience in your interview.

- Provide specific examples of your work experience.

4. Be Enthusiastic and Professional

First impressions matter, so be sure to be enthusiastic and professional during your interview. Dress appropriately, arrive on time, and be respectful of the interviewer.

- Dress appropriately for the interview.

- Arrive on time for your interview.

- Be respectful of the interviewer.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Primer Assembler role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.