Are you gearing up for a career in Tap Builder? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Tap Builder and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

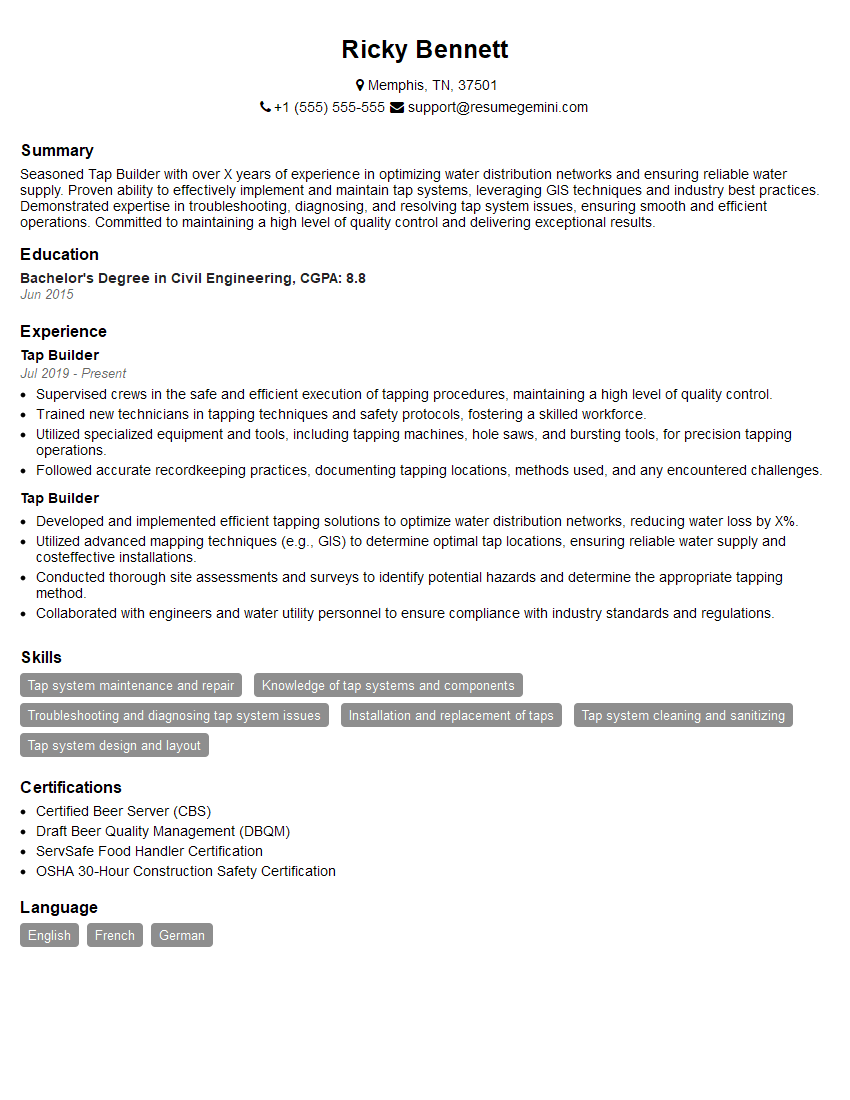

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tap Builder

1. How do you prioritize and manage multiple projects simultaneously?

As a Tap Builder, I prioritize projects based on their impact, urgency, and deadline. I use a project management tool to keep track of project details, set milestones, and monitor progress. I also communicate regularly with stakeholders to ensure that everyone is aware of the project status and any changes that may affect the schedule. To manage multiple projects simultaneously, I break them down into smaller tasks, delegate responsibilities to my team, and set realistic timelines. I also use automation tools to streamline certain tasks and free up my time.

2. Describe your experience creating and implementing custom tap buildouts.

Planning and Execution

- Conduct site surveys to determine the scope of the project and identify potential challenges.

- Design and engineer tap buildouts that meet the specific requirements of the client.

- Obtain necessary permits and approvals from the appropriate authorities.

Materials Selection and Procurement

- Select high-quality materials that meet industry standards and client specifications.

- Establish relationships with reliable suppliers to ensure timely delivery of materials.

- Manage inventory to minimize waste and optimize resources.

Construction and Installation

- Supervise the construction team to ensure that all aspects of the buildout meet the design specifications.

- Install and test all equipment to ensure proper functionality.

- Obtain final inspections and certifications to confirm compliance with regulations.

3. How do you approach troubleshooting and resolving tap system issues?

When troubleshooting tap system issues, I follow a systematic approach to identify and resolve the problem efficiently. I start by gathering information about the issue, including when it occurred, any error messages, and any recent changes to the system. I then inspect the system visually to identify any obvious signs of damage or malfunction. Next, I perform diagnostic tests to pinpoint the root cause of the problem. Once the cause is identified, I develop and implement a solution, which may involve repairing or replacing faulty components, adjusting settings, or updating software. I thoroughly test the system after implementing the solution to ensure that the issue is resolved and the system is functioning properly.

4. Describe your knowledge of tap system components and their functions.

Tap systems consist of various components that work together to provide clean, safe drinking water. Key components include:

- Taps: Dispensers that deliver water from the system.

- Filters: Remove impurities and contaminants from the water.

- Waterlines: Pipes that carry water from the source to the taps.

- Pressure regulators: Control the water pressure in the system.

- Tanks: Store water and maintain a reserve for use.

- Chillers: Cool the water to a desired temperature.

- Carbonators: Saturate the water with carbon dioxide to create sparkling water.

- Sanitation systems: Prevent the growth of bacteria and other microorganisms in the water.

5. How do you ensure the quality and consistency of tap water?

Maintaining the quality and consistency of tap water is crucial for the health and satisfaction of users. I implement the following measures to ensure that the water meets high standards:

- Regular maintenance: Conduct routine inspections and cleanings of all system components.

- Water testing: Perform regular water quality tests to monitor for contaminants and ensure compliance with regulations.

- Source protection: Identify and address potential sources of contamination in the water supply.

- Treatment optimization: Adjust filtration and other treatment processes as needed to improve water quality.

- Customer feedback: Monitor customer feedback and address any concerns promptly.

6. How do you stay up-to-date with advancements in tap system technology?

The tap system industry is constantly evolving with technological advancements. To stay current, I employ the following strategies:

- Industry events: Attend trade shows and conferences to learn about new products and technologies.

- Online resources: Subscribe to industry publications and websites to access the latest news and research.

- Training and certifications: Participate in manufacturer-led training programs and obtain industry certifications to enhance my knowledge.

- Networking: Connect with other professionals in the field to exchange information and insights.

7. How do you handle collaborating with cross-functional teams?

Collaborating with cross-functional teams is essential for successful tap system projects. I approach collaboration in the following ways:

- Communication: Establish clear lines of communication and maintain regular updates with all team members.

- Shared goals: Align on project objectives and ensure that everyone understands their roles and responsibilities.

- Respect and empathy: Value the perspectives and expertise of others, and approach interactions with respect and understanding.

- Conflict resolution: Facilitate constructive discussions and find solutions that address the needs of all stakeholders.

8. How do you manage and control project costs while maintaining quality?

Managing project costs while maintaining quality requires a proactive approach. I utilize the following strategies:

- Budget planning: Develop detailed project budgets that account for all materials, labor, and equipment costs.

- Cost monitoring: Track actual costs against the budget and identify areas for optimization.

- Value engineering: Explore alternative materials and construction methods to reduce costs without compromising quality.

- Supplier negotiations: Negotiate favorable pricing and terms with suppliers to minimize expenses.

- Quality control: Implement rigorous quality control measures to prevent costly rework and ensure the longevity of the tap system.

9. How do you ensure that tap systems meet safety regulations and industry standards?

Ensuring compliance with safety regulations and industry standards is paramount. I adhere to the following practices:

- Code knowledge: Maintain a comprehensive understanding of relevant building codes and safety regulations.

- System design: Design tap systems in accordance with established standards and best practices.

- Material selection: Use materials that meet or exceed industry standards for durability and safety.

- Installation: Follow proper installation procedures and obtain necessary permits and inspections.

- Regular maintenance: Perform routine inspections and maintenance to ensure ongoing compliance.

10. How do you approach sustainability in your tap system designs?

Promoting sustainability is an integral part of my design process:

- Water conservation: Incorporate fixtures and appliances that minimize water usage.

- Energy efficiency: Utilize energy-efficient equipment and design systems to reduce energy consumption.

- Material selection: Select sustainable materials that have a low environmental impact.

- Waste reduction: Minimize waste during installation and maintenance by using reusable components and recycling materials.

- Education and awareness: Educate clients on sustainable practices and encourage responsible water usage.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tap Builder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tap Builder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tap Builders play a pivotal role in the production of custom taps and cutting tools. Their responsibilities encompass:

1. Tap Design and Engineering

Analyzing customer specifications and requirements to design and engineer custom taps

- Selecting appropriate materials, coatings, and geometries

- Using CAD software to create technical drawings and specifications

2. Tap Manufacturing

Supervising and operating CNC machines to manufacture taps

- Setting up and calibrating machines, tools, and fixtures

- Monitoring production processes to ensure quality and efficiency

3. Quality Control and Testing

Inspecting and testing taps to verify conformance to specifications

- Using gauges, measuring equipment, and microscopes

- Conducting performance tests to evaluate cutting efficiency and accuracy

4. Customer Support

Providing technical support and advice to customers

- Troubleshooting tap performance issues

- Recommending appropriate tap solutions for specific applications

Interview Tips

To ace the Tap Builder interview, consider these tips:

1. Research the Company and Position

Gain insights into the company’s products, services, and industry reputation.

- Review the company website, LinkedIn profile, and industry publications

- Identify specific aspects of the position that align with your skills and experience

2. Prepare for Technical Questions

Anticipate questions related to tap design, manufacturing processes, and quality control.

- Practice answering questions about tap geometry, materials, and coatings

- Review your knowledge of CNC machining and inspection techniques

3. Highlight Transferable Skills

Showcase your skills and experience that are applicable to the role, even if not directly related to tap building.

- Emphasize your problem-solving abilities, attention to detail, and teamwork skills

- Provide examples of projects or experiences that demonstrate your proficiency in these areas

4. Ask Informed Questions

Prepare thoughtful questions to ask the interviewer, demonstrating your interest in the role and the company.

- Inquire about the company’s product development process or customer service philosophy

- Ask about opportunities for professional growth and career advancement

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tap Builder interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.