Are you gearing up for an interview for a Wire Mesh Filter Fabricator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Wire Mesh Filter Fabricator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

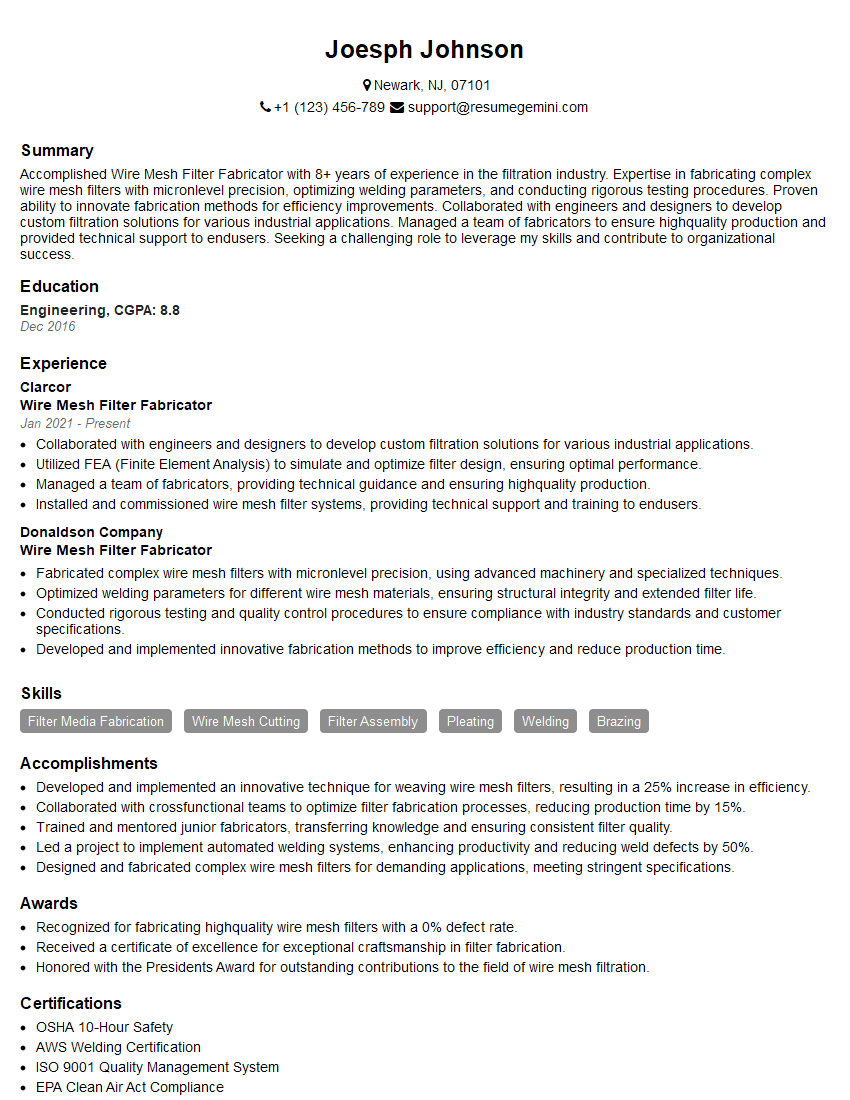

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wire Mesh Filter Fabricator

1. Describe the different types of weave patterns used in wire mesh filter fabrics?

- Plain weave: Interwoven perpendicular strands with alternating over and under construction.

- Twill weave: Diagonal pattern with strands passing over and under multiple adjacent strands.

- Dutch weave: Similar to twill, but with a steeper diagonal angle.

- Satin weave: Smooth surface created by multiple strands passing over a single strand.

2. How do you determine the appropriate mesh size for a specific filtration application?

Factors to Consider:

- Particle size and shape

- Flow rate and pressure drop

- Filter media properties (porosity, permeability)

- Desired filtration efficiency

Calculation Methods:

- Using sieves or laser particle size analyzers

- Referencing industry standards or manufacturer’s guidelines

3. Explain the importance of corrosion resistance in wire mesh filter fabrics?

- Prevents degradation due to chemical exposure

- Maintains structural integrity and filtration performance

- Extends filter life and reduces maintenance costs

- Complies with industry standards and regulations

4. What are the different methods used to fabricate wire mesh filters?

- Weaving: Interweaving wire strands to create the desired mesh pattern

- Knitting: Forming mesh from interlocked loops of wire

- Electroforming: Depositing metal onto a mold to create a mesh structure

- Sintering: Bonding wire particles together to form a porous mesh

5. How do you ensure the precision and consistency of mesh size and weave patterns?

- High-quality raw materials: Using uniform and consistent wire diameters

- Precise machinery: Employing state-of-the-art weaving or knitting machines

- Quality control: Implementing strict inspection processes and using calibrated measuring instruments

- Adherence to industry standards: Meeting or exceeding industry specifications for mesh size and weave tolerances

6. What factors influence the flow rate through a wire mesh filter?

- Mesh size: Smaller mesh sizes restrict flow

- Wire diameter: Thicker wires impede flow

- Porosity: Open areas in the mesh allow for flow

- Viscosity of fluid: Higher viscosity fluids flow slower

- Pressure drop: A pressure difference drives flow through the filter

7. How do you determine the appropriate alloy for a wire mesh filter?

- Corrosion resistance: Exposure to chemicals and environments

- Strength and durability: Filter pressure and mechanical loads

- Temperature resistance: Operating conditions and fluid temperatures

- Magnetic permeability: Applications involving magnetic fields

- Regulatory compliance: Meeting industry standards and regulations

8. Explain the different types of surface treatments applied to wire mesh filters and their benefits?

- Galvanizing: Zinc coating for corrosion resistance

- Electropolishing: Smoothening the mesh surface for better filtration

- Teflon coating: Reducing surface adhesion and improving chemical resistance

- Sintering: Bonding wire particles for higher strength and porosity

9. How do you calculate the required mesh count for a specific filtration application?

- Using filtration efficiency formula or tables

- Considering particle size, fluid properties, and desired filtration rate

- Selecting a mesh count that balances efficiency and flow rate

10. What are the common quality control tests performed on wire mesh filter fabrics?

- Tensile strength test: Measuring the resistance to breaking

- Corrosion resistance test: Exposing the mesh to corrosive environments

- Mesh count inspection: Verifying the number of openings per inch

- Porosity test: Determining the percentage of open area

- Visual inspection: Identifying any defects or imperfections

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wire Mesh Filter Fabricator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wire Mesh Filter Fabricator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Wire Mesh Filter Fabricator plays a pivotal role in crafting wire mesh filters for industrial applications, ensuring efficient filtration and enhancing equipment performance. Their core responsibilities encompass:

1. Wire Mesh Fabrication

Meticulously cutting, bending, and shaping wire mesh to precise specifications, utilizing specialized tools and machinery.

- Collaborating with design engineers to interpret blueprints and determine fabrication parameters.

- Selecting appropriate wire mesh materials, considering factors such as filtration efficiency, durability, and compatibility.

2. Filter Assembly

Assembling wire mesh filters according to design specifications, ensuring accuracy and structural integrity.

- Adhering to quality control standards throughout the assembly process.

- Testing filters for proper fit and performance before finalization.

3. Equipment Maintenance

Maintaining and troubleshooting fabrication equipment, ensuring optimal performance and minimizing downtime.

- Conducting regular inspections and preventive maintenance tasks.

- Performing basic repairs and adjustments to keep equipment in good working condition.

4. Quality Assurance

Inspecting fabricated filters against specifications and customer requirements, ensuring adherence to standards.

- Utilizing measuring and testing equipment to verify dimensional accuracy and performance characteristics.

- Maintaining detailed records of inspections and test results.

Interview Tips

Preparing for a job interview as a Wire Mesh Filter Fabricator requires a well-rounded approach. Here are some tips and hacks to help you ace it:

1. Research the Company and Position

Thoroughly research the company’s background, industry standing, and the specific requirements of the job. This knowledge will reflect in your answers, demonstrating your interest and enthusiasm.

- Visit the company’s website, social media pages, and industry news articles to gather insights.

- Analyze the job description to identify the core skills and experience the employer is seeking.

2. Highlight Relevant Skills and Experience

During the interview, emphasize your proficiency in wire mesh fabrication techniques, filter assembly, and quality assurance practices. Quantify your accomplishments whenever possible.

- Provide specific examples of projects where you successfully fabricated and assembled wire mesh filters.

- Quantify your results, such as increased filtration efficiency or reduced downtime.

3. Demonstrate Your Attention to Detail

Wire mesh filter fabrication demands precision and attention to detail. Showcase your meticulous nature by providing examples of your accuracy and thoroughness.

- Explain your process for ensuring the dimensional accuracy of fabricated filters.

- Describe how you maintain detailed records and conduct rigorous inspections.

4. Ask Informed Questions

Asking thoughtful questions at the end of the interview demonstrates your engagement and interest in the position. It also allows you to gather additional information.

- Inquire about the company’s future projects or growth plans.

- Ask about the specific challenges and opportunities associated with the role.

5. Follow Up Professionally

After the interview, send a thank-you note to the hiring manager within 24 hours. Reiterate your interest in the position and briefly summarize your qualifications.

- Express your gratitude for the opportunity to interview.

- Reiterate your interest in the position and highlight any key points you want to emphasize.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wire Mesh Filter Fabricator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!