Are you gearing up for an interview for a Automated Manufacturing Instructor position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Automated Manufacturing Instructor and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

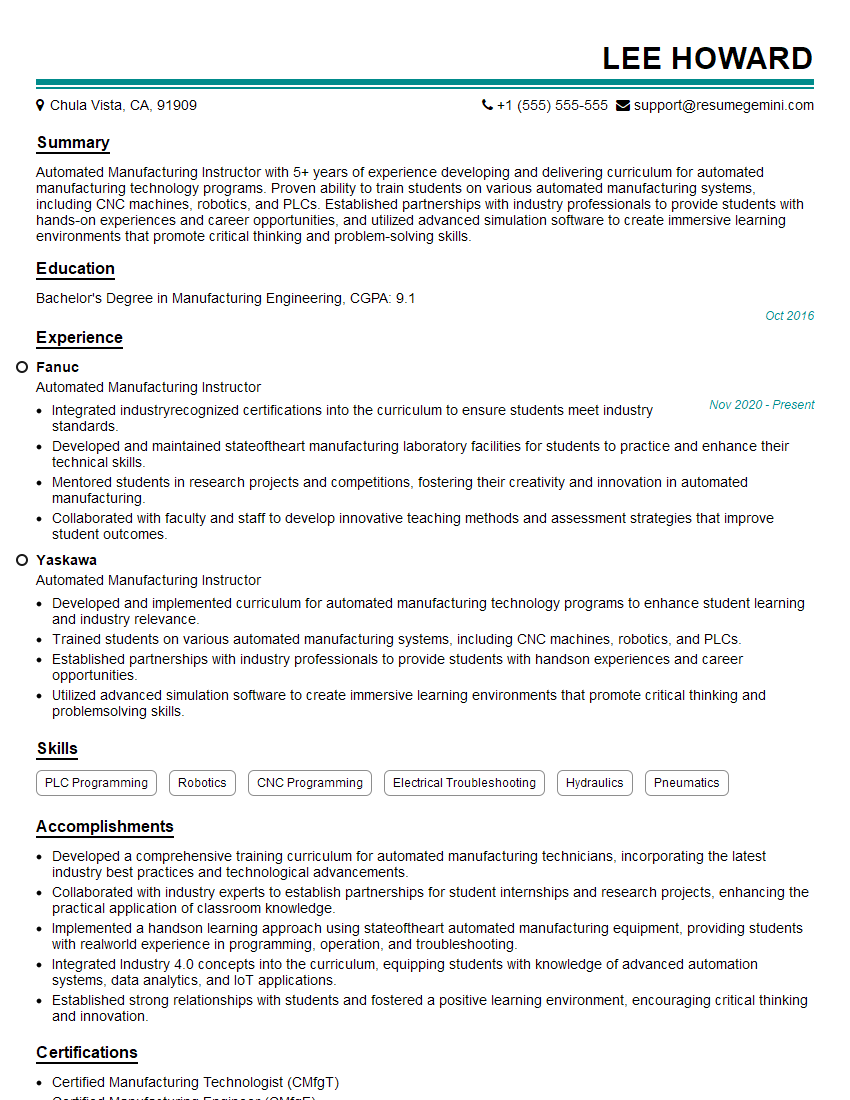

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Automated Manufacturing Instructor

1. How do you stay up-to-date with the latest advancements in automated manufacturing?

To stay up-to-date with the latest advancements in automated manufacturing, I regularly engage in professional development activities. This includes attending industry conferences, webinars, and workshops, as well as reading technical journals and research papers. I also maintain active memberships in professional organizations, such as the Society of Manufacturing Engineers (SME) and the Robotic Industries Association (RIA), to stay connected with other professionals in the field and gain insights into emerging technologies. Additionally, I actively seek opportunities to collaborate with industry experts and participate in research projects to stay at the forefront of innovation.

2. Describe your experience in developing and implementing automated manufacturing systems.

- Conducted thorough assessments of manufacturing processes to identify areas suitable for automation.

- Designed and implemented automated systems using various technologies, including robotics, programmable logic controllers (PLCs), and sensors.

- Integrated automated systems with existing manufacturing equipment and software applications.

- Developed and executed test plans to ensure system performance and reliability.

- Monitored and evaluated automated systems to identify areas for improvement and optimization.

3. How do you assess the effectiveness of automated manufacturing systems?

- Establish key performance indicators (KPIs) aligned with manufacturing goals, such as increased productivity, reduced costs, and improved quality.

- Collect and analyze data on system performance, including production rates, downtime, and defect rates.

- Compare actual performance against established KPIs to identify areas for improvement.

- Conduct regular audits and inspections to ensure systems are operating as intended.

- Seek feedback from operators and maintenance personnel to identify potential issues and areas for optimization.

4. What are your strategies for troubleshooting and resolving issues with automated manufacturing systems?

- Utilize diagnostic tools and techniques to identify the root cause of system malfunctions.

- Analyze system logs and error messages to pinpoint the source of problems.

- Collaborate with engineers and maintenance personnel to develop and implement solutions.

- Implement preventive maintenance strategies to minimize system downtime and ensure optimal performance.

- Document and share troubleshooting procedures to facilitate knowledge transfer and improve problem-solving efficiency.

5. How do you ensure that automated manufacturing systems are operated safely and efficiently by your students?

- Develop and implement comprehensive training programs that cover safety protocols, system operation, and maintenance procedures.

- Provide hands-on training opportunities for students to familiarize them with the equipment and its functionality.

- Supervise students during system operation to ensure adherence to safety guidelines and best practices.

- Establish clear expectations and guidelines for safe and efficient system usage.

- Regularly assess students’ understanding of safety procedures and provide feedback to reinforce learning.

6. How do you incorporate industry best practices and advancements into your teaching curriculum?

- Stay up-to-date with the latest industry standards and technologies through professional development activities.

- Incorporate real-world case studies and projects into the curriculum to provide students with practical experience.

- Collaborate with industry professionals to develop and deliver guest lectures and workshops.

- Utilize industry-standard software and equipment in the teaching lab to familiarize students with the tools used in the field.

- Encourage students to participate in industry competitions and events to gain exposure to best practices.

7. How do you assess student learning and progress in automated manufacturing?

- Utilize a variety of assessment methods, including written exams, practical assignments, and project-based evaluations.

- Provide detailed feedback on student performance to identify areas for improvement and foster growth.

- Track student progress over time to monitor their understanding and skill development.

- Involve students in self-assessment and reflection to encourage active participation in their learning process.

- Seek feedback from industry professionals who serve as guest speakers or mentors to evaluate student preparedness.

8. What are your strategies for engaging students in the learning process and fostering their interest in automated manufacturing?

- Utilize hands-on activities, simulations, and demonstrations to make learning interactive and engaging.

- Incorporate project-based learning to provide students with opportunities to apply their knowledge and solve real-world problems.

- Facilitate group discussions and collaborative projects to encourage peer-to-peer learning.

- Relate automated manufacturing concepts to real-world applications to demonstrate its relevance.

- Invite industry professionals to share their experiences and insights to inspire students.

9. How do you stay up-to-date with the latest advancements in educational technology and incorporate it into your teaching?

- Attend workshops and conferences on educational technology to explore new tools and strategies.

- Read journals and research papers to stay informed about emerging trends in education.

- Experiment with different educational technologies to identify those that are most effective for teaching automated manufacturing.

- Incorporate simulations, virtual reality, and online learning platforms to enhance student engagement and understanding.

- Provide students with access to online resources and learning communities to support their ongoing development.

10. How do you promote diversity and inclusion in your classroom and encourage students from all backgrounds to pursue careers in automated manufacturing?

- Create a welcoming and inclusive classroom environment where all students feel valued and respected.

- Actively recruit students from diverse backgrounds to participate in automated manufacturing programs.

- Provide mentorship and support to students from underrepresented groups to help them succeed in the field.

- Incorporate diverse perspectives and experiences into the curriculum to broaden students’ understanding.

- Collaborate with community organizations and industry partners to provide outreach programs and scholarships for students from disadvantaged backgrounds.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Automated Manufacturing Instructor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Automated Manufacturing Instructor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Automated Manufacturing Instructor is responsible for teaching students the principles and practices of automated manufacturing. They provide instruction on the use of automated equipment, robotics, and computer-aided design (CAD) software. Additionally, they may also develop and implement lesson plans, evaluate student progress, and maintain a safe and productive learning environment.

1. Develop and Implement Lesson Plans

Automated Manufacturing Instructors develop and implement lesson plans that align with the curriculum and educational standards. They identify learning objectives, select instructional materials, and determine appropriate teaching methods.

- Create lesson plans that cover the principles and practices of automated manufacturing.

- Incorporate hands-on activities and simulations to reinforce learning.

2. Instruct Students on Automated Manufacturing Equipment

Automated Manufacturing Instructors provide instruction on the use of automated manufacturing equipment, including robots, CNC machines, and automated assembly lines. They explain the operation and programming of these machines and ensure that students are able to use them safely and efficiently.

- Teach students how to program and operate robots and CNC machines.

- Explain the principles of automated assembly lines and how to troubleshoot problems.

3. Instruct Students on Computer-Aided Design (CAD) Software

Automated Manufacturing Instructors also provide instruction on the use of CAD software. They teach students how to create 3D models of products, design parts, and generate tool paths for CNC machines.

- Teach students how to use CAD software to create 3D models and design parts.

- Explain the principles of CAM software and how to generate tool paths for CNC machines.

4. Assess Student Progress

Automated Manufacturing Instructors assess student progress through a variety of methods, including tests, quizzes, and hands-on assessments. They provide feedback to students on their performance and help them to identify areas for improvement.

- Administer tests and quizzes to assess student understanding of concepts.

- Evaluate student projects and hands-on demonstrations to assess their skills.

Interview Tips

Preparing for an interview for an Automated Manufacturing Instructor position can be daunting, but by following these tips, you can increase your chances of success:

1. Research the School and Position

Take the time to learn about the school and the position you are applying for. Visit the school’s website, read the job description, and talk to people who work in the field. This will give you a better understanding of the school’s culture and the expectations of the position.

- Visit the school’s website to learn about its mission, vision, and values.

- Read the job description carefully to identify the key responsibilities and qualifications.

- Talk to people who work in the field to get insights into the profession.

2. Prepare for Common Interview Questions

There are a number of common interview questions that you can expect to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. Take the time to prepare your answers to these questions in advance so that you can deliver them confidently and concisely.

- Practice answering common interview questions out loud.

- Get feedback from a friend or family member on your answers.

3. Highlight Your Skills and Experience

Make sure to highlight your skills and experience in your resume and cover letter. Be specific about your experience teaching automated manufacturing or related subjects. If you have any relevant certifications or training, be sure to mention them as well.

- In your resume, use action verbs to describe your experience.

- In your cover letter, tailor your experience to the specific requirements of the position.

4. Dress Professionally and Arrive on Time

First impressions matter, so make sure to dress professionally for your interview. Arrive on time and be prepared to answer questions about your experience and qualifications.

- Wear business attire to your interview.

- Arrive on time and be prepared to answer questions.

Next Step:

Now that you’re armed with the knowledge of Automated Manufacturing Instructor interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Automated Manufacturing Instructor positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini