Are you gearing up for an interview for a Textile Machinery Instructor position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Textile Machinery Instructor and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

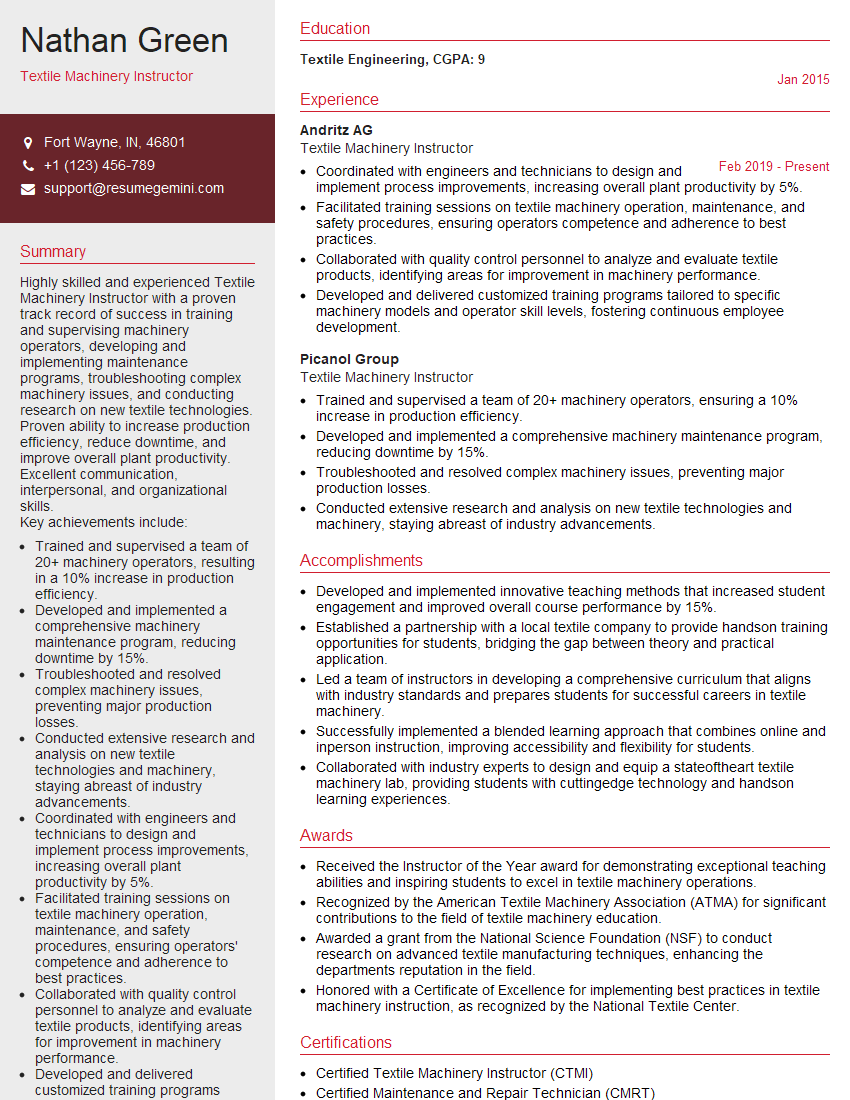

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Textile Machinery Instructor

1. Explain the key components of a weaving loom?

A weaving loom consists of the following key components:

- Warp beam: Holds the warp yarns.

- Cloth beam: Winds the woven fabric.

- Heddle frames: Separate the warp yarns and create the shed.

- Picking mechanism: Inserts the weft yarn into the shed.

- Beating mechanism: Pushes the weft yarn into place.

- Selvage: Helps to prevent the fabric edges from unraveling.

2. Describe the different types of warping machines?

Beam warping machine

- Produces a beam of warp yarns.

- Suitable for large-scale production.

Sectional warping machine

- Produces a set of sectional beams.

- Used for smaller production runs.

Ball warping machine

- Produces a ball of warp yarns.

- Used for special applications, such as knitting.

3. How do you maintain the accuracy of a knitting machine?

Maintaining the accuracy of a knitting machine involves:

- Regular cleaning and lubrication.

- Checking and adjusting needle settings.

- Inspecting and replacing worn or damaged parts.

- Using high-quality yarns.

- Calibrating the machine regularly.

4. What are the different types of dyeing methods used in the textile industry?

- Stock dyeing: Dyeing fibers before they are spun into yarn.

- Yarn dyeing: Dyeing yarns before they are woven or knitted.

- Piece dyeing: Dyeing fabric after it has been woven or knitted.

- Garment dyeing: Dyeing finished garments.

- Printing: Applying color to fabric using a variety of methods, such as screen printing, digital printing, and transfer printing.

5. What are the factors that affect the quality of a woven fabric?

- Yarn quality

- Weave pattern

- Machine settings

- Finishing processes

- Environmental conditions

6. How do you troubleshoot a problem with a textile machine?

Troubleshooting a problem with a textile machine involves:

- Identifying the symptoms of the problem.

- Checking for obvious causes, such as broken threads or loose parts.

- Consulting the machine manual or manufacturer’s website.

- Using diagnostic tools, such as a multimeter or oscilloscope.

- Replacing or repairing worn or damaged parts.

7. What are the safety precautions that should be taken when working on textile machinery?

- Wearing appropriate personal protective equipment (PPE), such as safety glasses, earplugs, and gloves.

- Keeping the work area clean and free of obstructions.

- Following lockout/tagout procedures before servicing machines.

- Being aware of potential hazards, such as moving parts and electrical equipment.

- Reporting any unsafe conditions or practices.

8. How do you stay up-to-date on the latest advances in textile machinery?

- Reading industry publications and attending trade shows.

- Networking with other textile professionals.

- Taking continuing education courses.

- Researching online resources.

- Visiting manufacturers’ websites and showrooms.

9. What are the different types of textile fiber materials?

- Natural fibers: Cotton, wool, silk, linen, jute

- Man-made fibers: Polyester, nylon, acrylic, rayon, spandex

- Regenerated fibers: Viscose, modal, lyocell

10. How do you develop a training program for textile machinery operators?

Developing a training program for textile machinery operators involves:

- Identifying the skills and knowledge that operators need.

- Creating lesson plans and training materials.

- Determining the most effective training methods.

- Providing hands-on training on actual machinery.

- Evaluating the effectiveness of the training program.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Textile Machinery Instructor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Textile Machinery Instructor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Textile Machinery Instructors are responsible for educating and training individuals on the operation, maintenance, and repair of textile machinery. Their duties typically include:

1. Instruction

Instructing students on the principles, theories, and techniques related to textile machinery operations.

- Preparing and delivering lectures, demonstrations, and hands-on training sessions.

- Providing guidance and feedback to students on their progress and performance.

- Evaluating student learning through assessments, exams, and practical assignments.

2. Training

Developing and implementing training programs to enhance the skills and knowledge of textile machinery operators and technicians.

- Identifying training needs through assessment and consultation with industry professionals.

- Designing and delivering customized training modules to address specific skill gaps.

- Mentoring and supporting trainees throughout the learning process.

3. Curriculum Development

Creating and updating curriculum materials and resources to support instruction and training.

- Conducting research on industry best practices and technological advancements.

- Developing course outlines, lesson plans, and training manuals.

- Incorporating new knowledge and techniques into the curriculum.

4. Collaboration

Collaborating with industry partners, manufacturers, and other stakeholders to stay abreast of industry trends and advancements.

- Attending industry conferences, seminars, and workshops.

- Consulting with industry experts and practitioners.

- Establishing partnerships for internships, apprenticeships, and research opportunities.

Interview Tips

To ace the interview for a Textile Machinery Instructor position, it’s important to:

1. Research and Preparation

Thoroughly research the institution, the program, and the job responsibilities to demonstrate your understanding and interest.

- Review the institution’s website and course offerings.

- Study the program’s curriculum and identify your relevant skills and experience.

- Prepare questions to ask the interviewer that show your engagement and knowledge of the field.

2. Highlight Your Expertise

Emphasize your expertise in textile machinery operations, maintenance, and repair.

- Provide specific examples of projects you’ve led or technical problems you’ve solved.

- Quantify your accomplishments whenever possible to demonstrate impact.

- Explain how your experience aligns with the curriculum and training needs of the program.

3. Showcase Your Teaching Skills

Demonstrate your ability to effectively communicate and teach complex technical concepts.

- Share examples of your teaching methods, such as hands-on training, interactive simulations, or group discussions.

- Discuss your experience in creating and delivering engaging and informative lesson plans.

- Explain how you assess student learning and provide feedback to promote progress.

4. Enthusiasm and Passion

Convey your enthusiasm for teaching and your passion for textile machinery.

- Express your interest in sharing your knowledge and skills with students.

- Explain how you stay up-to-date with industry advancements and incorporate them into your teaching.

- Mention any personal experiences or projects that reflect your passion for textiles or machinery.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Textile Machinery Instructor, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Textile Machinery Instructor positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.