Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Granulator Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

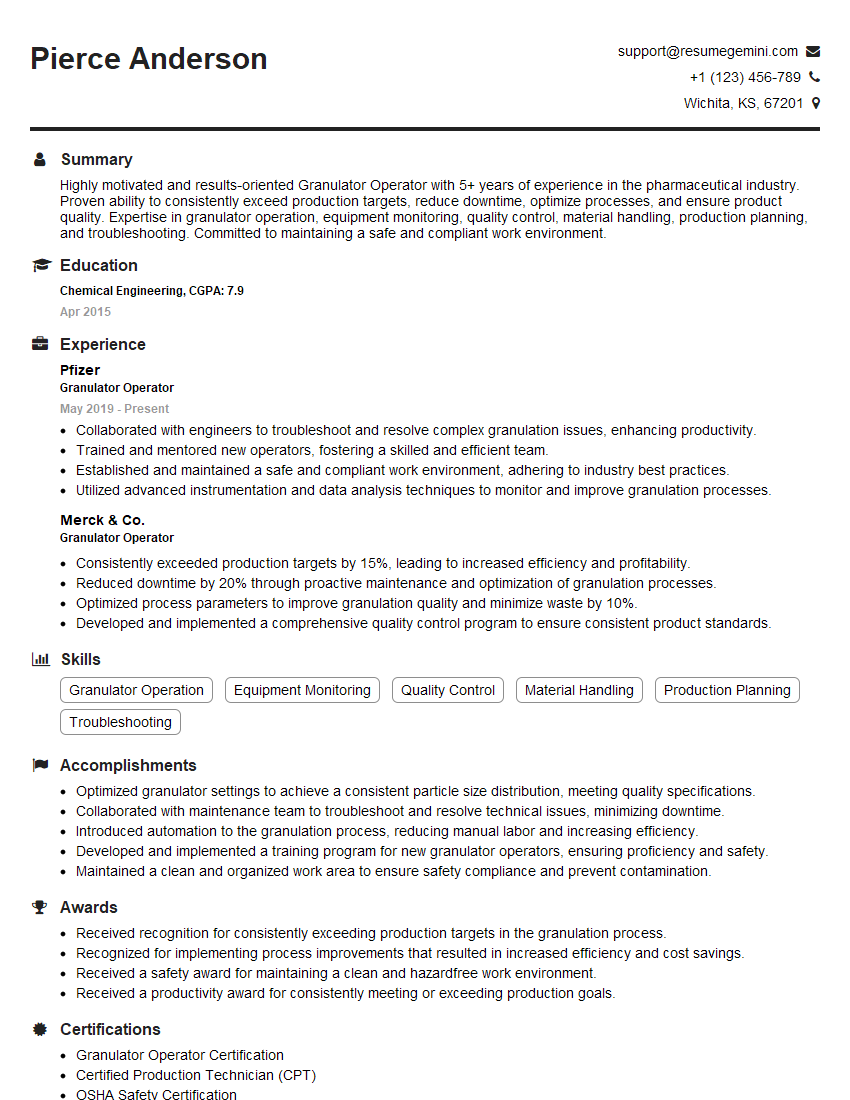

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Granulator Operator

1. Describe the process of granulation and its importance in the manufacturing industry?

Granulation is a process of converting a powder or liquid into small granules. It is used in various industries, such as pharmaceuticals, food, and chemical manufacturing. Granulation is important because it improves the flowability and handling of the material, reduces dust formation, and increases the density of the material.

- Improved flowability and handling

- Reduced dust formation

- Increased density of the material

2. Explain the different types of granulators and their applications?

Dry Granulation

- Roll compaction

- Slugging

Wet Granulation

- High Shear Granulation

- Fluid Bed Granulation

Melt Granulation

- Congealing

- Prilling

3. What are the key factors to consider when selecting a granulator?

- The type of material being granulated

- The desired particle size and shape

- The production capacity required

- The available budget

4. Describe the operation and maintenance procedures for a granulator?

The operation and maintenance procedures for a granulator vary depending on the type of granulator. In general, the operator must ensure that the granulator is properly calibrated and maintained to produce granules of the desired size and shape. The operator must also monitor the granulator’s performance and make adjustments as necessary.

- Proper calibration and maintenance

- Monitoring the granulator’s performance

- Making adjustments as necessary

5. What are the common problems that can occur in granulation and how can they be solved?

- Insufficient granulation: This can be solved by increasing the impeller speed, the amount of binder, or the granulation time.

- Over-granulation: This can be solved by decreasing the impeller speed, the amount of binder, or the granulation time.

- Dust formation: This can be solved by increasing the humidity of the granulation environment or by using a dust collector.

- Equipment failure: This can be solved by following the manufacturer’s maintenance and repair instructions.

6. What are the safety precautions that must be observed when operating a granulator?

- Wear appropriate personal protective equipment, such as eye protection, gloves, and a dust mask.

- Do not operate the granulator if it is not properly guarded.

- Do not reach into the granulator while it is running.

- Follow the manufacturer’s instructions for operating and maintaining the granulator.

7. What are the quality control measures that must be implemented in a granulation process?

- Granule size distribution: This can be measured using a sieve analysis.

- Moisture content: This can be measured using a moisture analyzer.

- Binder content: This can be measured using a chemical analysis.

- Bulk density: This can be measured using a pycnometer.

8. What are the recent advancements in granulation technology?

- Continuous granulation: This is a process that produces granules continuously, rather than in batches.

- High shear granulation: This is a process that uses a high shear force to granulate materials.

- Fluid bed granulation: This is a process that uses a fluidized bed of air to granulate materials.

9. What are the future trends in granulation technology?

- Increased automation: Granulation processes will become more automated, with less human intervention.

- Improved process control: Granulation processes will be more closely controlled, resulting in a more consistent product.

- Development of new granulation techniques: New granulation techniques will be developed to meet the demands of new materials and applications.

10. What are your strengths and weaknesses as a Granulator Operator?

My strengths include my experience in operating and maintaining granulators, my knowledge of granulation technology, and my ability to troubleshoot problems. My weakness is that I am not yet familiar with all of the latest advancements in granulation technology.

- Strengths:

- Experience in operating and maintaining granulators

- Knowledge of granulation technology

- Ability to troubleshoot problems

- Weaknesses:

- Not yet familiar with all of the latest advancements in granulation technology

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Granulator Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Granulator Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Granulator Operators play a crucial role in ensuring efficient and safe operations in a granulation plant. Their key responsibilities include:

1. Granulator Machine Operation

Operate granulator machinery, including rotary, fluidized bed, and high-shear granulators, to produce granules with specified characteristics.

- Adjust machine parameters (e.g., speed, temperature, feed rate) to optimize granulation process.

- Monitor granulation process to ensure product quality, including granule size, shape, and moisture content.

2. Batch Management

Manage granulation batches throughout the process, from raw material preparation to finished product packaging.

- Weigh and mix raw materials according to batch specifications.

- Control batch variables (e.g., granulating solution concentration, binder addition) to meet product requirements.

- Label and package finished granules as per batch specifications and quality standards.

3. Process Control

Monitor and control production parameters to maintain consistent granule quality and yield.

- Analyze granulate samples to assess granule size distribution, porosity, and other properties.

- Investigate and troubleshoot process deviations, identify root causes, and implement corrective actions.

- Adhere to established operating procedures and quality control standards.

4. Equipment Maintenance

Participate in granulator machine maintenance and cleaning to ensure optimal equipment performance.

- Follow maintenance schedules and perform routine inspections.

- Lubricate and clean machine components to minimize wear and tear.

- Report equipment malfunctions promptly and assist maintenance personnel in repairs.

Interview Tips

To help you ace your Granulator Operator interview, consider the following tips:

1. Research and Industry Knowledge

Demonstrate your understanding of the granulation process and industry trends. Research the company and its products to show your interest and enthusiasm for the role.

- Prepare examples of how you have applied granulation principles in previous roles.

- Stay updated on advancements in granulation technology and discuss how you can contribute to the company’s operations.

2. Technical Skills and Experience

Highlight your proficiency in granulator machine operation, process control, and equipment maintenance. Quantify your experience and provide specific examples.

- Describe the specific granulator machines you have operated and your level of expertise.

- Explain how you have optimized granulation processes to improve product quality and yield.

- Share your experience in troubleshooting equipment malfunctions and implementing effective repairs.

3. Quality Assurance and Regulatory Compliance

Emphasize your commitment to quality assurance and regulatory compliance. Show that you are familiar with industry standards and practices.

- Describe your experience in conducting granulate sample analysis and maintaining process documentation.

- Explain how you have adhered to Good Manufacturing Practices (GMP) and other quality standards.

- Discuss your understanding of regulatory requirements related to granulation processes.

4. Soft Skills and Teamwork

Granulator Operators often work in teams and communicate with other departments. Highlight your soft skills, such as communication, teamwork, and problem-solving.

- Provide examples of how you have effectively communicated with colleagues, supervisors, and customers.

- Describe your experience in working as part of a team to achieve common goals.

- Share your approach to problem-solving and decision-making in a granulation environment.

Next Step:

Now that you’re armed with the knowledge of Granulator Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Granulator Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini