Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Kiln Firer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

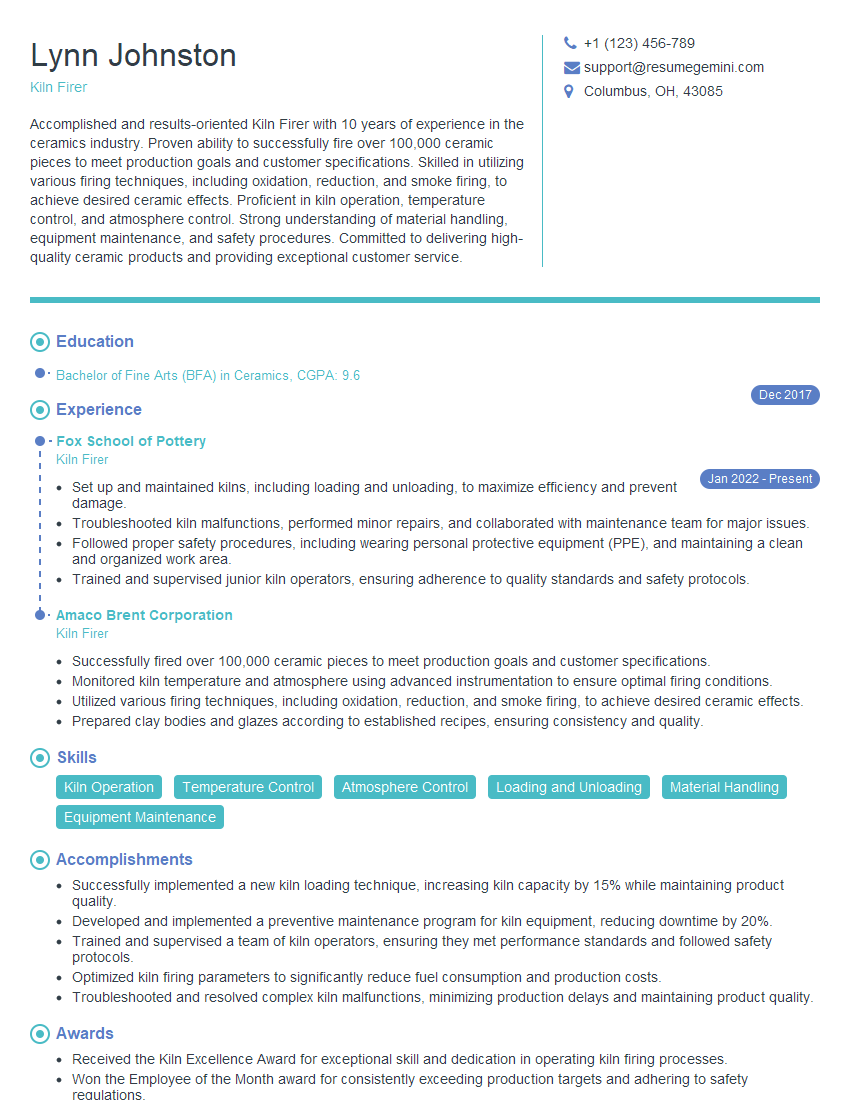

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Kiln Firer

1. What are the key responsibilities of a Kiln Firer?

The key responsibilities of a Kiln Firer include:

- Loading and unloading kilns

- Monitoring and maintaining kiln temperatures

- Performing quality checks on fired products

- Maintaining a clean and safe work area

- Following safety procedures

2. What is the firing process for ceramic products?

Loading the Kiln

- Prepare the kiln by inspecting it for any damage.

- Load the kiln shelves with the ceramic pieces, making sure that they are evenly spaced and not touching each other.

- Close the kiln door and seal it.

Firing the Kiln

- Turn on the kiln and set the temperature and firing schedule.

- Monitor the kiln temperature and make adjustments as needed.

- Once the firing is complete, turn off the kiln and allow it to cool.

Unloading the Kiln

- Once the kiln is cool enough, open the door and unload the ceramic pieces.

- Inspect the ceramic pieces for any damage.

3. What are the different types of kilns and their uses?

The different types of kilns and their uses include:

- Electric kilns: Electric kilns are the most common type of kiln used by ceramic artists. They are relatively easy to use and maintain, and they can fire a variety of ceramic materials.

- Gas kilns: Gas kilns are fired by natural gas or propane. They can reach higher temperatures than electric kilns, and they are often used for firing large pieces or for producing certain types of glazes.

- Wood-fired kilns: Wood-fired kilns are fired by wood. They can produce unique results, but they are more difficult to control than electric or gas kilns.

4. What are the safety precautions that must be taken when working with kilns?

The safety precautions that must be taken when working with kilns include:

- Always wear protective clothing, including gloves, safety glasses, and a respirator.

- Never open the kiln door while it is firing.

- Allow the kiln to cool completely before unloading it.

- Be aware of the location of the fire extinguisher.

- Never leave a kiln unattended.

5. What are the signs of overfiring or underfiring in ceramic products?

Overfiring

- The ceramic piece is warped or deformed.

- The ceramic piece has a glassy surface.

- The ceramic piece is brittle and easily broken.

Underfiring

- The ceramic piece is porous and absorbs water.

- The ceramic piece has a dull surface.

- The ceramic piece is weak and easily broken.

6. How do you troubleshoot common problems with kilns?

Common problems with kilns and their troubleshooting solutions include:

- The kiln is not heating up.

- Check the power supply to the kiln.

- Check the heating elements for damage.

- Check the kiln controller for proper operation.

- The kiln is heating up too quickly.

- Check the kiln controller for proper operation.

- Reduce the amount of fuel or power being supplied to the kiln.

- The kiln is not cooling down.

- Check the kiln door to make sure it is closed properly.

- Check the kiln controller for proper operation.

7. What are the qualities of a successful Kiln Firer?

The qualities of a successful Kiln Firer include:

- Attention to detail

- Ability to follow instructions

- Ability to work independently

- Ability to work in a team environment

- Strong work ethic

8. What is your experience with different types of kilns?

I have experience with a variety of kilns, including electric, gas, and wood-fired kilns. I am familiar with the different firing processes and the safety precautions that must be taken when working with each type of kiln.

9. Can you describe a time when you had to troubleshoot a problem with a kiln?

I once had to troubleshoot a problem with an electric kiln that was not heating up. I checked the power supply to the kiln and the heating elements, but they were both working properly. I then checked the kiln controller and found that it was not functioning properly. I replaced the kiln controller and the kiln started working again.

10. What are your goals for this position?

My goals for this position are to learn more about the different types of kilns and firing processes, and to develop my skills as a Kiln Firer. I am also interested in learning more about the different types of ceramic materials and glazes that can be used in kiln firing.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Kiln Firer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Kiln Firer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Kiln firers play a vital role in the manufacturing process of ceramics and other materials by operating and maintaining kilns to achieve precise firing temperatures and conditions.

1. Kiln Operation and Maintenance

Efficiently operate kilns by loading, unloading, and monitoring firing processes to ensure optimal production.

- Calibrate and adjust kilns to achieve and maintain desired temperatures and firing conditions.

- Monitor kiln performance, identify and troubleshoot any issues, and perform necessary repairs and maintenance.

2. Quality Control and Process Management

Ensure the quality of fired products by adhering to established firing protocols and specifications.

- Conduct regular inspections of fired products to identify and address any defects or variations.

- Maintain accurate records of kiln operations, firing parameters, and product quality for traceability and process optimization.

3. Safety and Environmental Compliance

Prioritize safety and adhere to environmental regulations throughout kiln operations.

- Follow proper safety protocols, including wearing appropriate protective gear and handling hazardous materials safely.

- Monitor and control kiln emissions to comply with environmental regulations and minimize environmental impact.

4. Collaboration and Communication

Effectively collaborate with other production team members to ensure seamless operations.

- Communicate effectively with supervisors, engineers, and colleagues to provide updates on kiln operations and product quality.

- Participate in quality improvement initiatives and share knowledge to enhance production processes.

Interview Tips

To ace your interview for a Kiln Firer position, it is crucial to prepare effectively and showcase your relevant skills and experience.

1. Research the Company and Role

Thoroughly research the company and the specific job requirements. This will demonstrate your interest and help you tailor your answers to the interviewer’s expectations.

- Visit the company’s website and social media pages to learn about their values, culture, and recent projects.

- Analyze the job description and identify the key responsibilities and qualifications that you possess.

2. Highlight Your Technical Skills

Emphasize your technical expertise in kiln operation, temperature control, and quality control procedures.

- Quantify your experience by providing specific examples of how you have successfully operated and maintained kilns.

- Discuss your understanding of different firing techniques and how you adjust these based on the material and desired results.

3. Demonstrate Your Safety and Environmental Awareness

Highlight your commitment to safety and adherence to environmental regulations.

- Explain your knowledge of hazardous materials handling and safe work practices in a kiln environment.

- Discuss your experience in monitoring and controlling kiln emissions to minimize environmental impact.

4. Showcase Your Team-Oriented Attitude

Emphasize your ability to work effectively in a team setting.

- Provide examples of how you have successfully collaborated with colleagues to solve problems and improve production processes.

- Highlight your communication skills and willingness to share knowledge and expertise.

5. Prepare for Common Interview Questions

Familiarize yourself with common interview questions and prepare thoughtful responses that highlight your qualifications.

- “Tell us about your experience in operating and maintaining kilns.”

- “How do you ensure the quality of fired products and address any defects?”

- “Describe your approach to safety and environmental compliance in a kiln environment.”

- “How do you collaborate with other team members to achieve production goals?”

- “Why are you interested in this position at our company?”

6. Be Enthusiastic and Professional

Maintain a positive and enthusiastic attitude throughout the interview.

- Dress professionally and arrive on time for the interview.

- Be confident in your abilities and demonstrate your passion for kiln firing.

- Thank the interviewer for their time and follow up with a brief thank-you email after the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Kiln Firer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!