Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Blending Plant Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

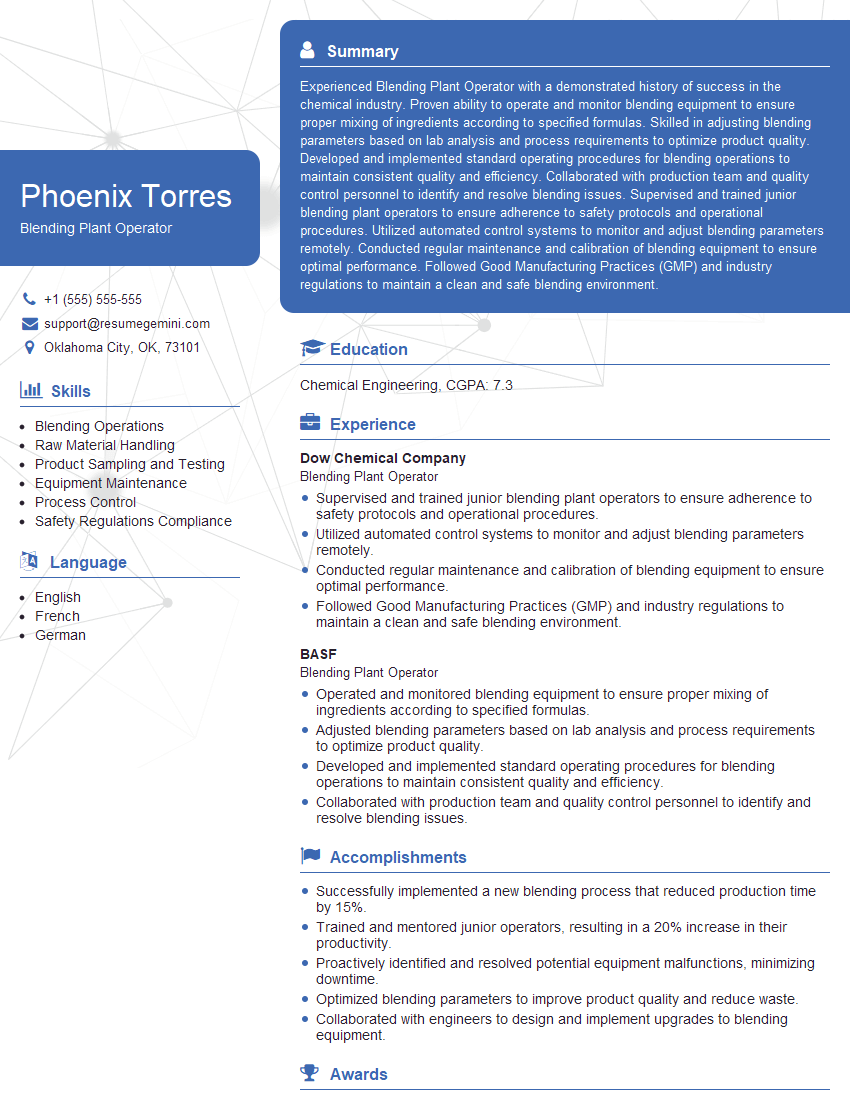

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Blending Plant Operator

1. Describe the process of blending different types of materials to create a specific blend.

- First, I would identify the different types of materials that need to be blended.

- Next, I would determine the proportions of each material that need to be used to create the desired blend.

- Once the proportions have been determined, I would weigh or measure each material and add it to the blender.

- I would then blend the materials together until they are evenly mixed.

- Finally, I would check the blend to make sure that it meets the desired specifications.

2. How do you ensure that the blended product meets the desired quality standards?

Sampling and testing

- I would take samples of the blended product and test them against the desired quality standards.

- If the samples do not meet the standards, I would adjust the blending process until the desired quality is achieved.

Visual inspection

- I would also visually inspect the blended product to make sure that it meets the desired specifications.

- I would look for any signs of contamination or other defects.

3. What are the potential hazards associated with blending different materials, and how do you mitigate them?

- The potential hazards associated with blending different materials include dust explosions, fires, and chemical spills.

- To mitigate these hazards, I would use proper ventilation, wear appropriate personal protective equipment, and follow all safety procedures.

4. How do you handle situations where there is a discrepancy between the desired blend and the actual blend?

- If there is a discrepancy between the desired blend and the actual blend, I would first try to identify the cause of the discrepancy.

- Once the cause has been identified, I would make adjustments to the blending process to correct the discrepancy.

- I would then retest the blend to make sure that it meets the desired specifications.

5. How do you maintain and calibrate the blending equipment?

- I would follow the manufacturer’s instructions for maintaining and calibrating the blending equipment.

- I would also keep a maintenance log to document all maintenance and calibration activities.

6. What are the different types of blending equipment, and what are their advantages and disadvantages?

Batch blenders

- Advantages: Batch blenders are relatively simple to operate and maintain.

- Disadvantages: Batch blenders can be slow and inefficient, and they are not suitable for blending large quantities of material.

Continuous blenders

- Advantages: Continuous blenders are more efficient than batch blenders, and they can be used to blend large quantities of material.

- Disadvantages: Continuous blenders are more complex to operate and maintain than batch blenders.

7. Describe the different types of blending processes, and what are their advantages and disadvantages?

Solid-solid blending

- Advantages: Solid-solid blending is a simple and efficient process.

- Disadvantages: Solid-solid blending can be difficult to control, and it can result in segregation of the materials.

Liquid-solid blending

- Advantages: Liquid-solid blending is a more precise process than solid-solid blending.

- Disadvantages: Liquid-solid blending can be more expensive and time-consuming than solid-solid blending.

Gas-solid blending

- Advantages: Gas-solid blending is a very efficient process.

- Disadvantages: Gas-solid blending can be difficult to control, and it can result in the formation of agglomerates.

8. What are the key factors that affect the efficiency of a blending process?

- The type of materials being blended

- The size and shape of the particles

- The density of the materials

- The moisture content of the materials

- The temperature of the materials

- The type of blending equipment being used

- The blending time

- The blending speed

9. How do you troubleshoot common problems that occur during blending?

- Segregation of the materials

- Agglomeration of the particles

- Contamination of the blend

- Equipment failure

10. What are the latest trends in blending technology?

- The use of computer-controlled blending systems

- The development of new blending equipment

- The use of new materials in blending

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Blending Plant Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Blending Plant Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Blending Plant Operator is accountable for overseeing the blending and packaging of various products within a manufacturing facility. This role requires a thorough understanding of blending processes, equipment operation, and quality control measures.

1. Blending Operation Management

Oversees blending operations by following established procedures and recipes

- Measures, weighs, and blends raw materials according to specified proportions

- Monitors and adjusts blending parameters such as temperature, mixing time, and speed

2. Equipment Operation and Maintenance

Ensures the efficient and safe operation of blending equipment

- Operates and monitors blenders, conveyors, and other related machinery

- Performs routine maintenance, cleaning, and troubleshooting of equipment

3. Quality Control and Assurance

Maintains high standards of product quality through rigorous quality control measures

- Conducts in-process and finished product testing to ensure adherence to specifications

- Maintains detailed records and documentation of blending operations and quality control activities

4. Safety Compliance and Housekeeping

Prioritizes safety and maintains a clean and organized work environment

- Adheres to all safety regulations and guidelines

- Maintains a clean and organized work area to prevent contamination and accidents

Interview Tips

Preparing thoroughly for an interview as a Blending Plant Operator can significantly increase your chances of success. Here are some practical tips to help you excel:

1. Research the Company and Role

Familiarize yourself with the company’s industry, products, and mission statement. Understand the specific responsibilities of the Blending Plant Operator role and how it aligns with your skills and experience.

- Visit the company’s website and social media pages

- Read industry news and reports to gain insights into the company’s market position

2. Highlight Relevant Experience and Skills

Tailor your resume and cover letter to emphasize your relevant experience in blending operations, equipment maintenance, and quality control. Quantify your accomplishments whenever possible using specific metrics.

- Showcase your knowledge of blending techniques, equipment troubleshooting, and quality control standards

- Provide examples of how you have improved blending processes or resolved operational issues

3. Practice Common Interview Questions

Prepare answers to common interview questions that focus on your technical skills, problem-solving abilities, and safety awareness.

- “Describe your experience in operating and maintaining blending equipment.”

- “How do you ensure the quality and consistency of blended products?”

- “Tell us about a time you faced a challenge in blending operations and how you overcame it.”

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview demonstrates your interest in the position and the company. Prepare questions that show your enthusiasm and seek clarification on aspects of the role or the company’s operations.

- “What is the company’s commitment to sustainability and environmental practices?”

- “What opportunities are there for professional development within the organization?”

- “How does the company encourage collaboration and teamwork among employees?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Blending Plant Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!