Feeling lost in a sea of interview questions? Landed that dream interview for Brewery Technician but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Brewery Technician interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

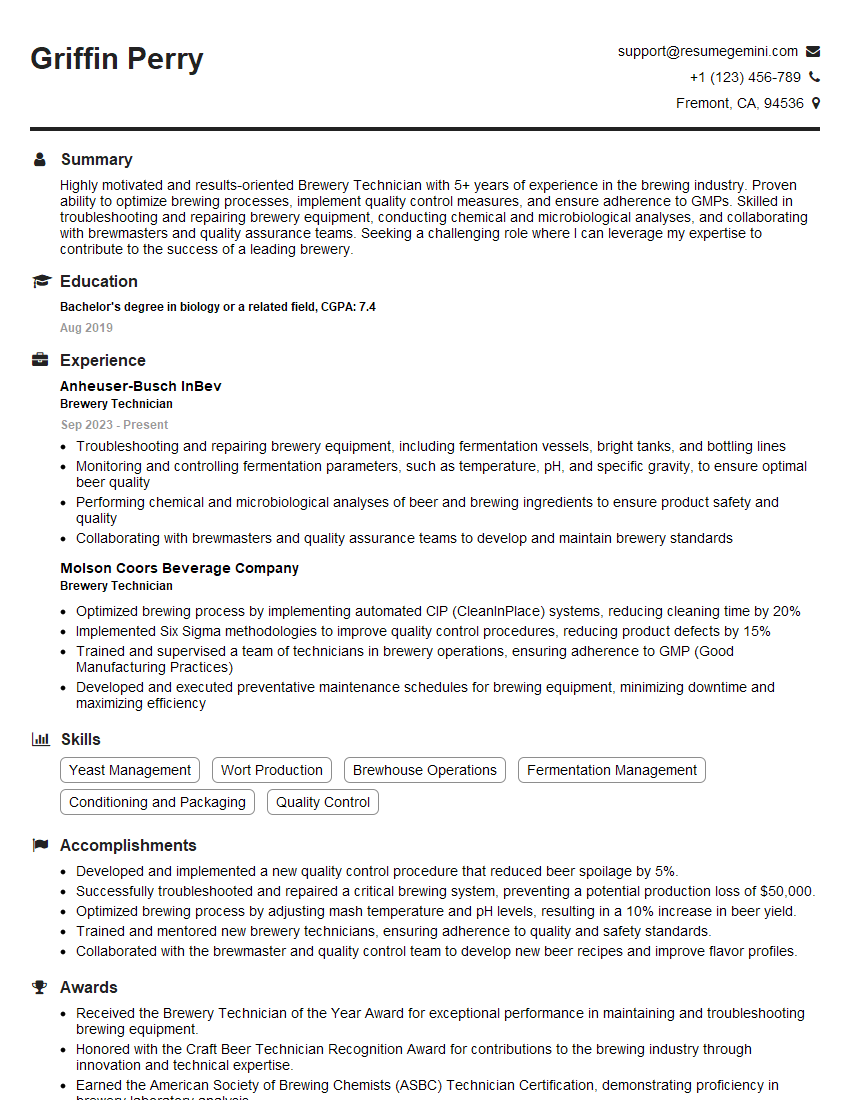

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Brewery Technician

1. What are the critical parameters to monitor during the fermentation process and how do you manage these parameters to ensure optimal yeast performance?

- Temperature: Maintain optimal temperature ranges for yeast growth and activity.

- pH: Control pH levels within a specific range to support yeast metabolism.

- Oxygen: Manage oxygen levels to prevent excessive growth or starvation.

- Nutrient availability: Monitor and supplement nutrients such as nitrogen, phosphorus, and vitamins for yeast health.

- Yeast cell count: Track yeast cell population to ensure adequate numbers and viability.

2. Describe the key elements of a malt analysis and how these factors impact the brewing process.

Moisture Content

- Influences mashing time and efficiency.

- High moisture content reduces fermentable sugars.

Extract

- Determines the potential alcohol content.

- Affects wort viscosity and fermentation kinetics.

Protein

- Contributes to foam stability.

- High protein levels can lead to hazy beer.

3. How do you optimize the lautering process to maximize wort quality and yield?

- Proper mashing temperature and grain bed formation.

- Controlled lautering rate and temperature.

- Use of filtration aids (e.g., kieselguhr) when necessary.

- Monitoring of lautering efficiency and wort clarity.

- Adjustment of sparge water volume and temperature.

4. Describe the principles of hop isomerization and its impact on beer flavor.

- Boiling temperature and duration affect isomerization rate.

- Isomerized alpha-acids provide bitterness.

- Isomerized beta-acids contribute to hop aroma.

- Proper hop utilization optimizes flavor and bitterness levels.

5. How do you troubleshoot common brewing equipment issues, such as stuck fermentations, clogged filters, and wort contamination?

- Physically inspect equipment for blockages or damage.

- Check temperature, pH, and nutrient levels.

- Utilize microscopes and other diagnostic tools to identify contaminants.

- Implement appropriate corrective actions (e.g., cleaning, adjustments, replacements).

- Document observations and take preventative measures to minimize future issues.

6. Explain the principles of beer filtration and describe the different types of filtration systems used in brewing.

- Removes yeast, haze-forming proteins, and other impurities.

- Types of filtration systems:

- Depth filtration (e.g., sheet filtration)

- Membrane filtration (e.g., microfiltration, ultrafiltration)

- Selection depends on desired beer quality, cost, and operational efficiency.

7. How do you calibrate and maintain brewery instrumentation, such as hydrometers, pH meters, and temperature probes?

- Follow manufacturer’s instructions for calibration.

- Use traceable standards and reference materials.

- Perform regular checks and adjustments.

- Document calibration records for quality assurance.

- Preventative maintenance to ensure accuracy and reliability.

8. Describe the quality control procedures you follow to ensure the production of safe and consistent beer.

- Raw material inspection and testing.

- In-process monitoring of critical parameters.

- Sensory evaluation and analysis.

- Microbiological testing and contamination control.

- Documentation and traceability of all processes.

9. Discuss the importance of good sanitation practices in the brewing process and how you implement these practices in your work.

- Prevents spoilage and contamination.

- Protects equipment and infrastructure.

- Ensures product quality and consistency.

- Practices include cleaning, sanitizing, and regular inspections.

- Adherence to sanitation protocols and industry best practices.

10. How do you stay up-to-date on the latest brewing techniques and advancements?

- Attend industry conferences and workshops.

- Read industry publications and journals.

- Participate in online forums and discussions.

- Collaborate with other brewers and professionals.

- Continuously research and experiment with new techniques.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Brewery Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Brewery Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Brewery Technicians are responsible for the operation and maintenance of brewing equipment, ensuring the production of high-quality beer while adhering to safety and quality standards.

1. Brewing Process Management

Operate and monitor brewing equipment, including mash tuns, lauter tuns, kettles, and fermenters.

- Control brewing parameters, such as temperature, pH, and fermentation rates, to ensure optimal conditions for beer production.

- Monitor and adjust water treatment systems to maintain water quality for brewing.

2. Equipment Maintenance and Troubleshooting

Perform routine maintenance and repairs on brewing equipment, including pumps, valves, and conveyors.

- Troubleshoot and resolve technical issues with brewing equipment to minimize downtime and maximize productivity.

- Conduct preventive maintenance inspections to identify potential problems and schedule repairs accordingly.

3. Quality Control and Compliance

Monitor and evaluate the quality of beer throughout the brewing process.

- Conduct sensory evaluations, chemical analyses, and microbiological testing to ensure that beer meets quality standards.

- Comply with all applicable laws and regulations governing the production and distribution of alcoholic beverages.

4. Health and Safety

Maintain a safe and sanitary work environment in the brewery.

- Follow established safety protocols, including wearing appropriate protective gear and observing proper lockout/tagout procedures.

- Enforce sanitation standards to prevent contamination and ensure the safety of beer products.

Interview Tips

To ace your Brewery Technician interview, it’s crucial to prepare both technically and interpersonally.

1. Technical Preparation

Review the key job responsibilities and familiarize yourself with the brewing process, equipment maintenance, and quality control procedures.

- Study industry best practices and stay up-to-date on technological advancements in brewing.

- Practice troubleshooting common brewing equipment issues.

2. Behavioral Preparation

Research the company culture and prepare examples of your work experience that demonstrate your skills and abilities as a Brewery Technician.

- Emphasize your attention to detail, problem-solving capabilities, and commitment to safety and quality.

- Highlight your ability to work both independently and as part of a team in a fast-paced environment.

3. Question Preparation

Prepare thoughtful questions to ask the interviewer, demonstrating your interest in the role and the company.

- Inquire about the brewery’s production capacity, beer portfolio, and quality control measures.

- Ask about the company’s commitment to sustainability and employee development.

4. Professionalism and Communication

Dress professionally, arrive on time, and maintain a positive and enthusiastic demeanor throughout the interview.

- Speak clearly and concisely, using technical terms appropriately.

- Listen attentively to the interviewer’s questions and respond thoughtfully.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Brewery Technician role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.