Are you gearing up for a career in Brewing Technician? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Brewing Technician and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

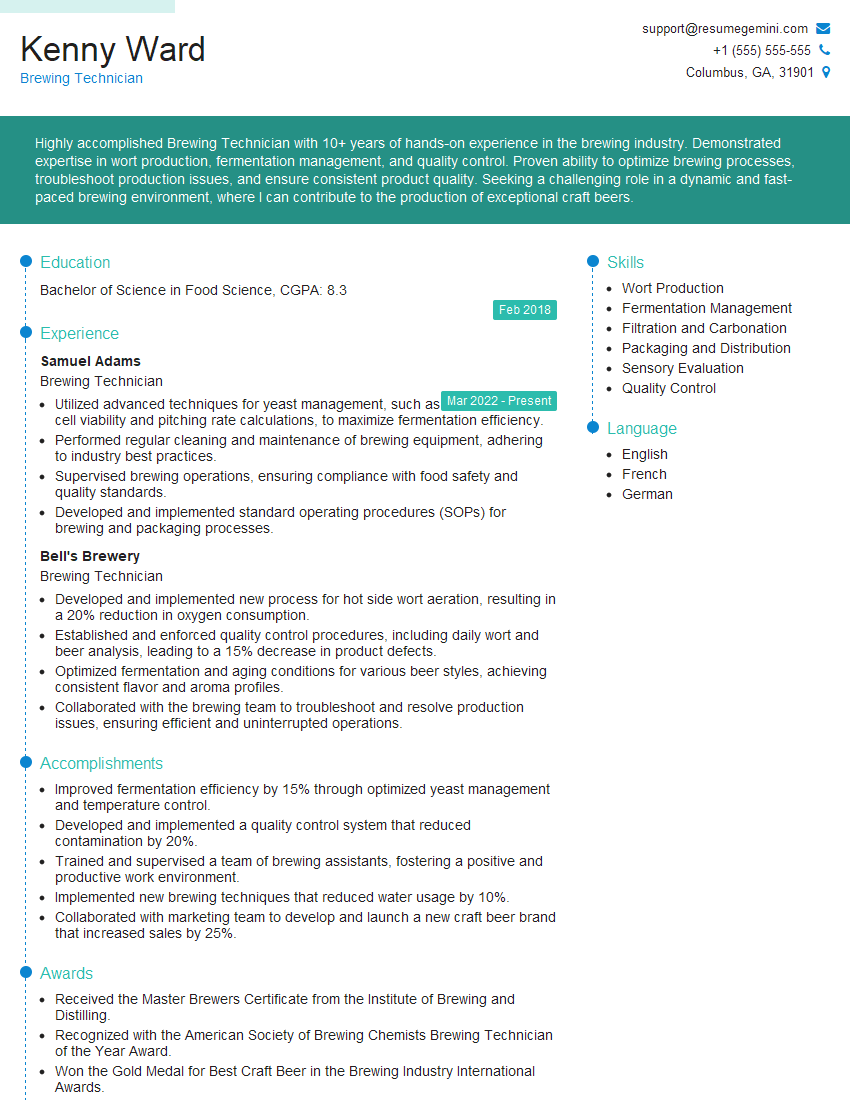

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Brewing Technician

1. What is the most important factor to consider when brewing beer?

The most important factor to consider when brewing beer is the quality of the ingredients. The quality of the malt, hops, water, and yeast will determine the quality of the finished beer. Other factors, such as the brewing process and the fermentation conditions, are also important, but they cannot compensate for poor-quality ingredients.

2. What are the key steps in the brewing process?

Milling

- The first step in the brewing process is to mill the malt. Milling breaks down the malt kernels into smaller pieces, which exposes the enzymes that will convert the starches in the malt into sugars.

Mashing

- The next step is to mash the milled malt with hot water. Mashing allows the enzymes in the malt to break down the starches into sugars. The temperature of the mash is critical, as it will affect the types of sugars that are produced.

Lautering

- After mashing, the wort is lautered. Lautering is the process of separating the sweet wort from the spent grain. The wort is then boiled.

Boiling

- Boiling the wort is the next step in the brewing process. Boiling kills any bacteria that may be present in the wort and it also helps to extract the flavors and aromas from the hops.

Fermentation

- After boiling, the wort is cooled and then fermented. Fermentation is the process by which yeast converts the sugars in the wort into alcohol and carbon dioxide.

Conditioning

- After fermentation, the beer is conditioned. Conditioning allows the beer to mature and develop its full flavor.

Packaging

- The final step in the brewing process is to package the beer. Beer can be packaged in a variety of ways, including bottles, cans, and kegs.

3. What are the different types of yeast used in brewing?

- There are two main types of yeast used in brewing: ale yeast and lager yeast.

- Ale yeast ferments at warmer temperatures (60-75°F) and produces beers with a fruity, estery flavor.

- Lager yeast ferments at cooler temperatures (45-55°F) and produces beers with a clean, crisp flavor.

4. What are the different types of hops used in brewing?

- There are many different varieties of hops used in brewing, each with its own unique flavor and aroma.

- Some of the most popular varieties include Cascade, Centennial, Chinook, and Amarillo.

- Hops are added to the wort at various stages of the brewing process to impart different flavors and aromas.

5. What are the different types of beer?

- There are many different styles of beer, each with its own unique characteristics.

- Some of the most popular styles include pale ale, IPA, stout, and lager.

- Beers can be classified by their color, flavor, aroma, and alcohol content.

6. What are the different types of brewing equipment?

- There are many different types of brewing equipment used in the brewing process.

- Some of the most important pieces of equipment include the mash tun, the lauter tun, the boil kettle, and the fermenter.

- The type of equipment used will vary depending on the size and type of brewery.

7. What are the different quality control procedures used in brewing?

- Quality control is an important part of the brewing process.

- Breweries use a variety of quality control procedures to ensure that their beers meet the highest standards.

- Some of the most common quality control procedures include testing the wort for specific gravity, pH, and bitterness.

8. What are the common problems that can occur during the brewing process?

- There are a number of common problems that can occur during the brewing process.

- Some of the most common problems include contamination, off-flavors, and poor fermentation.

- It is important for brewers to be able to identify and troubleshoot these problems in order to ensure that they are producing high-quality beer.

9. What are the safety procedures that must be followed in a brewery?

- Breweries are potentially hazardous environments.

- It is important for brewers to follow all safety procedures in order to prevent accidents.

- Some of the most important safety procedures include wearing protective clothing, using proper equipment, and following all safety protocols.

10. What are the career opportunities for brewing technicians?

- There are a variety of career opportunities for brewing technicians.

- Some of the most common career paths include working in a brewery, working for a brewing equipment manufacturer, or working as a brewing consultant.

- Brewing technicians can also work in other industries, such as the food and beverage industry or the pharmaceutical industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Brewing Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Brewing Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Brewing Technicians are scientists responsible for the production and maintenance of beer in breweries. Their primary function is to ensure that the beer meets established quality standards, adhering to industry guidelines and regulations.1. Brewing Process Management

- Developing, executing, and monitoring brewing schedules

- Controlling fermentation and maturation processes

- Conducting quality tests and evaluations at various stages

2. Equipment Maintenance and Calibration

- Inspecting, cleaning, and maintaining brewing equipment

- Calibrating and verifying instruments used in the brewing process

- Troubleshooting and resolving technical issues with equipment

3. Quality Assurance and Control

- Adhering to Good Manufacturing Practices (GMPs) and Quality Management Systems (QMS)

- Conducting regular laboratory tests to ensure product safety and quality

- Monitoring and maintaining production records

4. Sanitation and Hygiene

- Implementing and maintaining cleaning and sanitation protocols

- Enforcing sterile conditions during brewing and packaging

- Training and supervising staff on hygiene practices

Interview Tips

To ace an interview for a Brewing Technician position, consider the following tips:1. Technical Proficiency

- Review core concepts in chemistry, microbiology, and brewing science.

- Highlight your understanding of brewing processes, equipment, and quality control.

2. Practical Experience

- Emphasize your hands-on experience in breweries or similar settings.

- Provide specific examples of troubleshooting, equipment maintenance, and quality assurance projects.

3. Teamwork and Communication

- Showcase your ability to work effectively in a team environment.

- Highlight your communication skills and ability to interact with various stakeholders, including production, quality control, and management teams.

4. Industry Knowledge

- Demonstrate your knowledge of the brewing industry, including trends, regulations, and best practices.

- Discuss your interest in the specific brewery and its products.

5. Interview Preparation

- Research the brewery, its products, and its history.

- Prepare specific examples of your technical skills and accomplishments.

- Be prepared to discuss your motivation for pursuing a career as a Brewing Technician.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Brewing Technician interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.