Are you gearing up for an interview for a Candy Maker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Candy Maker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

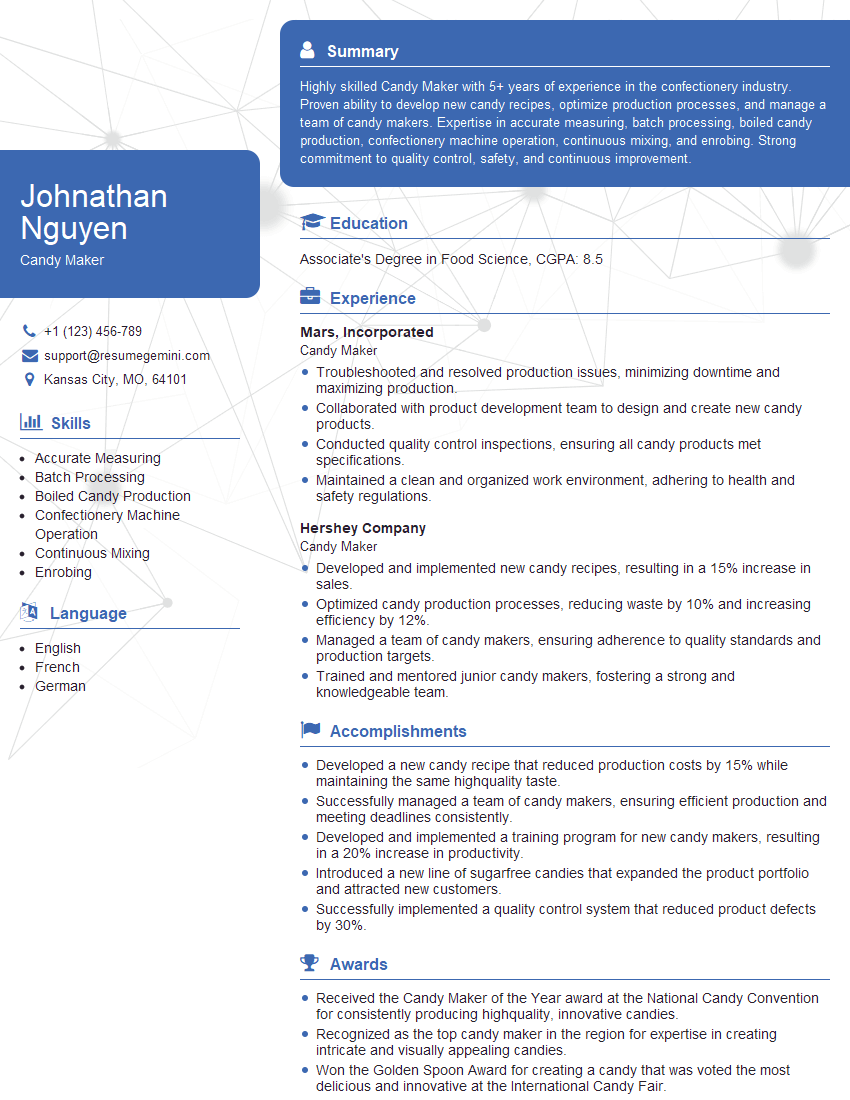

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Candy Maker

1. What is the most challenging aspect of candy making?

- Maintaining precise temperatures and timing is crucial, as even slight variations can alter the candy’s texture and quality.

- Balancing different ingredients and flavors to achieve the desired taste and consistency is a delicate task.

2. What is your favorite type of candy to make? Why?

Safety Precautions

- Knowledge of and adherence to all safety regulations is paramount.

- Proper handling of hot sugar and other potentially hazardous materials is essential.

Attention to Detail

- Meticulous attention to detail is required throughout the entire candy-making process.

- Precise measurements, careful cooking techniques, and proper storage are crucial.

3. What are the key ingredients in making candy?

- Sugar: The primary ingredient, providing sweetness and structure.

- Water: Helps dissolve sugar and prevent crystallization.

- Flavorings: Natural or artificial extracts, oils, or essences that add taste.

- Colors: Food-grade dyes or natural colorings that enhance visual appeal.

- Acid: Often added to balance sweetness and enhance flavor.

4. What are the different types of candy-making techniques?

- Boiling: Dissolving sugar in water and boiling until the desired consistency is reached.

- Creaming: Beating sugar and butter together to create a light and fluffy mixture.

- Caramelizing: Heating sugar until it melts and turns golden brown, adding a rich flavor.

- Fondant: Cooking sugar and water to form a soft, pliable paste.

- Tempering: Controlled heating and cooling of chocolate to achieve a smooth, glossy finish.

5. What are the common problems that occur during candy making?

- Crystallization: Undissolved sugar crystals forming in the candy.

- Scorching: Overheating the sugar mixture, resulting in a burnt flavor and color.

- Grainy texture: Insufficient stirring during cooking, leading to a rough texture.

- Separation: Ingredients not properly combined, causing the candy to separate.

- Environmental factors: Humidity and temperature can affect candy stability and texture.

6. How do you ensure the quality and consistency of your candies?

- Following standardized recipes and procedures.

- Using high-quality ingredients and proper equipment.

- Regularly calibrating and maintaining equipment.

- Monitoring temperatures and cooking times precisely.

- Sensory evaluation and customer feedback for continuous improvement.

7. What is the role of sugar in candy making?

- Provides sweetness and flavor.

- Forms the structure and texture of the candy.

- Prevents spoilage and extends shelf life.

- Affects the crystallization process and the final appearance of the candy.

- Contributes to browning reactions and flavor development.

8. How do you handle customer complaints or inquiries related to candy products?

- Listen attentively to the customer’s concerns.

- Investigate and identify the source of the issue.

- Provide clear and accurate information about the product and its ingredients.

- Offer solutions or replacements as appropriate.

- Maintain a professional and empathetic demeanor throughout the interaction.

9. What are the latest trends in candy making?

- Sugar reduction and the use of natural sweeteners.

- Incorporation of functional ingredients for health benefits.

- Artisanal and small-batch production.

- Innovative flavor combinations and textures.

- Emphasis on sustainability and ethical sourcing.

10. How do you stay up-to-date with advancements in candy making techniques and industry best practices?

- Attend industry conferences and workshops.

- Read trade publications and candy-making books.

- Network with other candy professionals.

- Experiment with new ingredients and techniques.

- Seek mentorship from experienced candy makers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Candy Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Candy Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Candy Makers are responsible for producing and packaging candy in a manufacturing setting. They must ensure that products meet quality standards and work in accordance with company policies.

1. Manufacturing Confectionery Products

Candy Makers operate various machines to produce candy. They monitor production lines, ensuring that the equipment is functioning correctly and making adjustments as needed. They also inspect raw materials and finished products to ensure that they meet quality standards.

- Operate candy-making machinery, such as extruders, mixers, and molding machines

- Monitor production lines to ensure that candies are produced according to specifications

- Make adjustments to machinery to optimize production

- Inspect raw materials and finished products to ensure quality

2. Packaging and Storing Products

Candy Makers package candy to prepare it for distribution. They weigh and measure candy, wrap it, and package it in boxes or other containers. They also store candy in a proper and safe manner.

- Weigh and measure candy to prepare it for packaging

- Wrap and package candy in boxes or other containers

- Store candy in a cool and dry environment

- Maintain a clean and organized work area

3. Maintaining Equipment

Candy Makers must keep machinery and equipment in good working condition. They perform basic maintenance and repairs, calibrate equipment, and ensure that it meets safety standards.

- Perform basic maintenance and repairs on candy-making machinery

- Calibrate equipment to ensure accuracy

- Maintain a safe working environment

- Follow all safety guidelines and regulations

4. Maintaining Quality Standards

Candy Makers must adhere to strict quality standards to ensure the safety and quality of their products. They inspect products, monitor production processes, and implement corrective actions when necessary.

- Inspect products to ensure quality

- Monitor production processes to ensure that they are in compliance with standards

- Implement corrective actions when necessary

- Maintain accurate records of production and quality control

Interview Tips

Preparing for an interview for a Candy Maker position requires learning about the role and the company, practicing your answers to common interview questions, and dressing appropriately.

1. Research the Role and the Company

Before the interview, research the responsibilities of a Candy Maker and the specific requirements of the position you are applying for. You should also learn about the company, its culture, and its products.

- Visit the company’s website and social media pages

- Read industry news and articles

- Network with people who work in the industry

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Why are you interested in this role?” and “What are your strengths and weaknesses?” Practice answering these questions in a clear and concise manner.

- Use the STAR method to answer behavioral questions

- Be prepared to talk about your experience and skills

- Be enthusiastic and positive

3. Dress Appropriately

First impressions matter, so it is important to dress appropriately for your interview. Business casual attire is typically acceptable for a Candy Maker interview.

- Wear a clean and pressed shirt and pants

- Wear comfortable shoes

- Avoid wearing excessive jewelry or makeup

4. Other Tips

Here are some additional tips to help you ace your interview:

- Arrive on time for your interview

- Be polite and respectful to everyone you meet

- Be prepared to ask questions

- Follow up with the interviewer after the interview

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Candy Maker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.