Are you gearing up for a career in Candy Forming Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Candy Forming Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

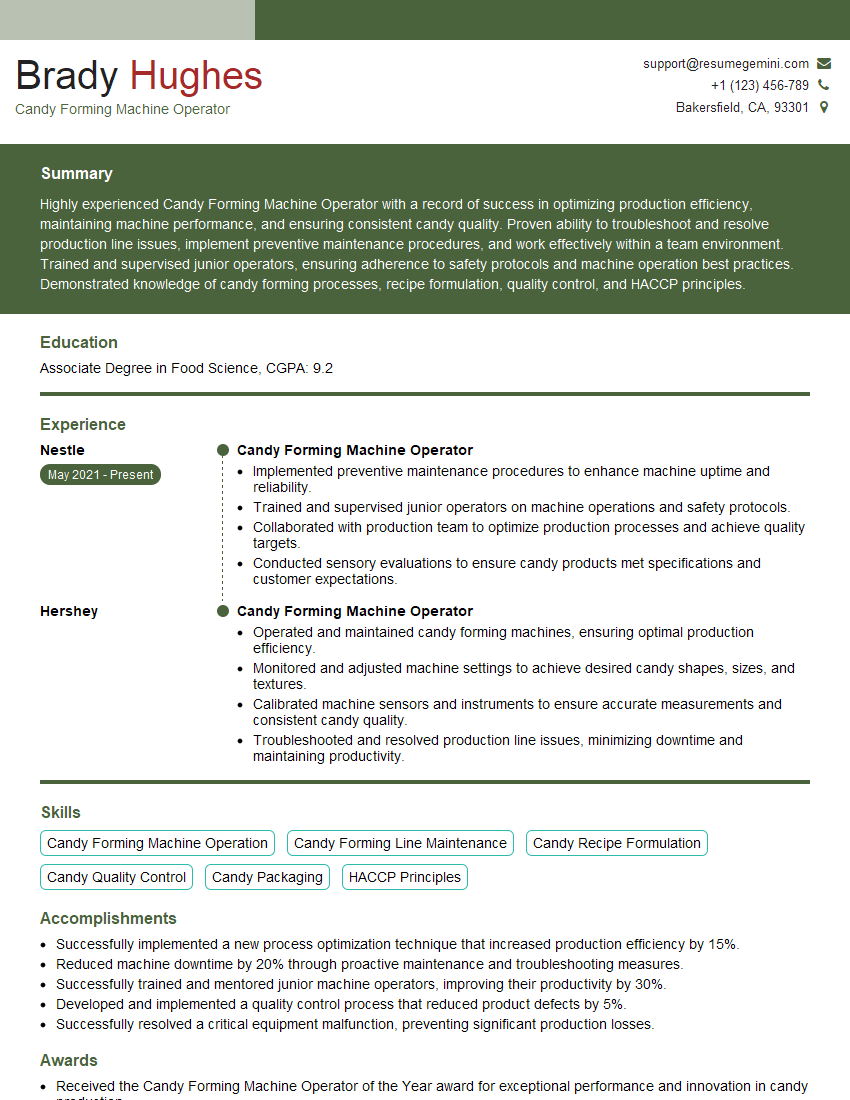

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Candy Forming Machine Operator

1. Explain the process of setting up and operating a candy forming machine?

Setting up and running a candy forming equipment is a multi-faceted process that involves the following crucial steps:

- Preparing the machine: Before commencing operations, the machine must be thoroughly cleaned and sterilized to ensure optimal hygiene standards.

- Setting machine parameters: Based on the desired candy specifications, parameters such as temperature, speed, and mold shape are meticulously configured.

- Loading raw materials: The appropriate candy mixture is carefully loaded into the machine’s hopper, ensuring a consistent supply throughout the production run.

- Starting the machine: Once the machine is correctly set up and loaded, it is powered on and closely monitored during the initial phase of operation.

- Monitoring and adjusting: Throughout the production process, vigilance is maintained to observe the candy formation and make necessary adjustments to the machine’s parameters, if required.

2. How do you maintain and troubleshoot a candy forming machine?

Daily Maintenance Checks:

- Regular cleaning and sanitization of all machine components

- Verifying proper lubrication and tension of moving parts

- Inspecting electrical connections and ensuring their integrity

Troubleshooting Common Issues:

- Candy not forming properly: Check mold alignment, temperature settings, and raw material consistency

- Machine blockages: Identify the blockage location and carefully remove any obstructions

- Electrical faults: Consult the machine’s manual for specific troubleshooting procedures and safety precautions

3. What safety precautions should be taken when operating a candy forming machine?

To ensure a safe operating environment, adherence to the following safety measures is paramount:

- Proper attire: Wear appropriate clothing, including safety glasses, gloves, and non-slip shoes

- Guarding against hazards: Ensure that all safety guards are securely in place and operational

- Electrical safety: Verify proper grounding and avoid operating the machine with wet hands

- Emergency procedures: Familiarize yourself with emergency stop buttons and evacuation routes

- Regular maintenance: Conduct routine maintenance checks to minimize the risk of breakdowns and potential hazards

4. How do you ensure the quality of candies produced by the machine?

Maintaining the quality of candies produced by the machine requires a comprehensive approach:

- Raw material inspection: Examine incoming raw materials to ensure they meet quality standards

- Process monitoring: Regularly monitor machine parameters, such as temperature and speed, to maintain consistency

- Visual inspection: Conduct visual checks of candies during production to identify any defects or inconsistencies

- Sensory evaluation: Periodically taste and evaluate candies to assess their flavor, texture, and overall quality

- Record keeping: Maintain accurate records of production parameters and quality control checks for traceability and continuous improvement

5. Explain the different types of candies that can be produced using a candy forming machine?

Candy forming machines offer versatility in producing a wide array of candies:

- Hard candies: Classic hard candies with smooth, glossy surfaces, such as lollipops and butterscotch

- Caramels: Soft and chewy candies with a rich, buttery flavor, often filled with ingredients like nuts or fruit

- Toffees: Similar to caramels but firmer in texture and often flavored with chocolate, vanilla, or coffee

- Gummies: Soft, gelatin-based candies available in various shapes and colors, often flavored with fruit or sour flavors

- Jellies: Vibrant and translucent candies made from fruit juices or pectin, offering a chewy texture

6. How do you handle and store formed candies to maintain their quality?

Proper handling and storage techniques are crucial to preserve the quality of formed candies:

- Cooling: Allow candies to cool completely before handling or packaging to prevent deformation

- Packaging: Store candies in airtight containers or packaging to prevent moisture absorption and contamination

- Temperature control: Maintain storage temperatures within the recommended range to prevent melting or hardening

- Inventory management: Implement a first-in, first-out (FIFO) system to ensure optimal freshness and quality

- Regular inspection: Periodically inspect stored candies for signs of spoilage or damage

7. Describe the cleaning and sanitation procedures for a candy forming machine?

Meticulous cleaning and sanitation are essential to maintain hygiene and prevent contamination:

- Daily cleaning: Regularly wipe down the machine’s exterior and accessible parts with a food-grade sanitizer

- Weekly deep cleaning: Dismantle the machine and thoroughly clean all components, including molds, hoppers, and conveyors

- Sanitation schedule: Follow a regular sanitation schedule to ensure the machine meets food safety standards

- Documentation: Maintain records of cleaning and sanitation procedures for traceability and compliance

- Training: Ensure that all operators are trained on proper cleaning and sanitation techniques

8. How do you optimize the efficiency of a candy forming machine?

Optimizing machine efficiency enhances productivity and reduces downtime:

- Preventive maintenance: Conduct regular maintenance checks to identify and address potential issues proactively

- Operator training: Train operators on efficient operating procedures and troubleshooting techniques

- Process optimization: Analyze production data to identify areas for improvement and implement process modifications

- Material handling improvements: Streamline raw material handling and minimize interruptions to the production flow

- Equipment upgrades: Consider upgrades to the machine’s components or automation capabilities to increase efficiency

9. What are the common challenges faced by candy forming machine operators, and how do you overcome them?

Common challenges and their solutions include:

- Machine breakdowns: Implement a preventive maintenance plan and train operators on basic troubleshooting

- Quality issues: Establish quality control procedures, monitor production parameters, and provide operator training

- Production delays: Optimize processes, minimize downtime, and ensure adequate staffing levels

- Safety hazards: Implement strict safety protocols, provide proper training, and maintain a clean and organized work area

- Equipment limitations: Explore upgrades or modifications to enhance machine capabilities and meet production demands

10. Describe your experience in working with different types of candy forming machines?

Throughout my career, I have gained extensive experience in operating various types of candy forming machines:

- Depositor machines: Capable of forming candies by depositing liquid candy mixture into molds

- Extrusion machines: Used to create elongated candies by forcing the mixture through a shaping die

- Rotary molding machines: Designed for high-volume production of candies with complex shapes

- Press machines: Employed to form candies by pressing the mixture into molds under pressure

- Enrobing machines: Utilized to coat candies with chocolate or other coatings

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Candy Forming Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Candy Forming Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Candy Forming Machine Operators are essential to the production of high-quality candy products. They are responsible for ensuring that the machines are running smoothly and producing candy according to specifications. Key job responsibilities include:

1. Preparing and setting up Candy Forming Machine

Candy Forming Machine Operators prepare and set up the candy forming machine according to the production schedule. They may also need to adjust the machine to produce different types of candy.

2. Loading and unloading the Candy Forming Machine

Candy Forming Machine Operators load the candy forming machine with raw materials, such as sugar, corn syrup, and flavorings. They also unload the finished candy from the machine and inspect it for defects.

3. Monitoring and adjusting the Candy Forming Machine

Candy Forming Machine Operators monitor the operation of the candy forming machine and make adjustments as needed. They may also need to troubleshoot problems with the machine.

4. Maintaining the Candy Forming Machine

Candy Forming Machine Operators are responsible for maintaining the candy forming machine. They may need to clean the machine, lubricate moving parts, and replace worn or damaged parts.

5. Maintaining a clean and safe work area

Candy Forming Machine Operators are responsible for maintaining a clean and safe work area. They may need to sweep the floor, clean the equipment, and dispose of waste.

Interview Tips

Preparing for an interview can be daunting, but there are some tips and tricks you can use to increase your chances of success. Here are some interview tips for Candy Forming Machine Operators:

1. Research the company and the position

Before you go on an interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and the specific requirements of the job. You can find information about the company on their website, social media pages, and news articles.

2. Practice answering common interview questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

3. Be prepared to talk about your experience

The interviewer will likely want to know about your experience as a Candy Forming Machine Operator. Be prepared to talk about your skills and experience in detail. You can also highlight any specific accomplishments or projects that you are proud of.

4. Ask questions

Asking questions at the end of the interview shows that you are interested in the position and that you are engaged in the conversation. It is also an opportunity for you to learn more about the company and the position. Some good questions to ask include:

- What are the biggest challenges facing the company right now?

- What are the growth opportunities for this position?

- What is the company culture like?

5. Follow up after the interview

After the interview, send a thank-you note to the interviewer. This is a simple way to show your appreciation for their time and to reiterate your interest in the position.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Candy Forming Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.