Are you gearing up for a career in Candy Puller? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Candy Puller and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

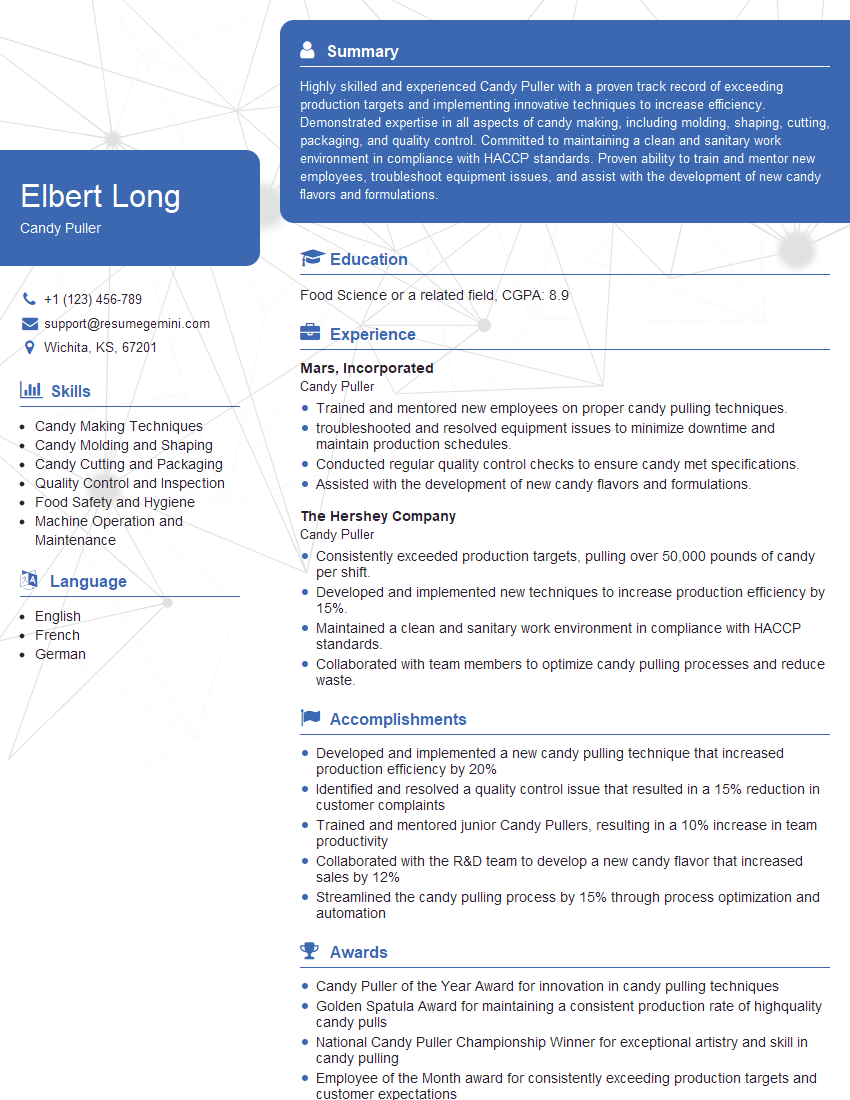

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Candy Puller

1. How do you ensure the consistency of candy quality from batch to batch?

- Establish clear specifications and quality control parameters for all ingredients and processes.

- Implement standardized operating procedures (SOPs) to guide production and ensure consistency.

- Regularly monitor and test raw materials and finished products to verify compliance with specifications.

- Calibrate and maintain equipment regularly to ensure accuracy and precision in measurements and production processes.

- Provide ongoing training and support to production staff on quality control practices.

2. Describe the process for developing and implementing new candy flavors or products.

Ideation and Concept Development

- Conduct market research to identify consumer preferences, trends, and unmet needs.

- Collaborate with product development team to brainstorm and generate new flavor ideas.

Formulation and Testing

- Develop and refine candy formulations, experimenting with ingredients, proportions, and flavors.

- Conduct sensory testing and consumer panels to gather feedback and optimize the flavor and texture.

Production and Launch

- Scale up production based on optimized formulation and establish SOPs for manufacturing.

- Develop packaging and marketing strategies to launch the new product successfully.

3. What techniques do you use to reduce waste and improve efficiency in candy production?

- Optimize production schedules and batch sizes to minimize downtime and maximize equipment utilization.

- Implement lean manufacturing principles to eliminate waste and improve overall efficiency.

- Recycle and reuse materials such as packaging and raw materials whenever possible.

- Invest in automated equipment and technologies to reduce manual labor and minimize errors.

- Monitor production data and key performance indicators (KPIs) to identify areas for improvement.

4. How do you troubleshoot and resolve production issues that may arise during candy production?

- Identify the root cause of the issue by gathering information and analyzing production data.

- Develop and implement corrective actions based on the identified root cause.

- Monitor the effectiveness of the corrective actions and make adjustments as needed.

- Document the troubleshooting process and share it with the production team to prevent recurrence.

- Establish a culture of continuous improvement and encourage staff to report and resolve issues promptly.

5. What are the key food safety and sanitation practices you follow in candy production?

- Implement and maintain a Hazard Analysis and Critical Control Points (HACCP) plan to identify and control potential food safety hazards.

- Adhere to Good Manufacturing Practices (GMPs) and follow strict sanitation protocols.

- Regularly clean and disinfect equipment, surfaces, and work areas to prevent contamination.

- Enforce proper hygiene practices among production staff, including handwashing and protective gear.

- Monitor and control the temperature and humidity of production environments to prevent spoilage.

6. Describe your experience in managing a team of candy production staff.

- Delegated responsibilities and tasks based on individual strengths and skills.

- Provided clear instructions, training, and support to ensure staff understanding.

- Monitored performance and provided feedback to promote growth and development.

- Fostered a positive and collaborative work environment to enhance team productivity.

- Recognized and rewarded staff contributions to maintain motivation and morale.

7. How do you stay up-to-date with the latest advancements and trends in candy production?

- Attend industry conferences and workshops to learn about new technologies and best practices.

- Read trade publications and journals to keep abreast of industry developments.

- Engage in networking with other professionals in the field and exchange knowledge.

- Participate in research and development projects to contribute to innovation in candy production.

- Seek out opportunities for professional growth and certification to enhance my knowledge and skills.

8. What is your understanding of the role of automation in modern candy production?

- Automation can increase production efficiency, accuracy, and consistency.

- It can reduce manual labor, minimize human error, and improve product quality.

- Automated systems can collect and analyze data, providing valuable insights for production optimization.

- However, it is important to carefully evaluate the cost-effectiveness and maintenance requirements of automated equipment.

- Collaboration between automation engineers and candy production experts is crucial to ensure successful implementation.

9. How do you ensure the safety of your team while working in a candy production facility?

- Develop and implement comprehensive safety protocols and training programs.

- Provide personal protective equipment (PPE) and ensure its proper use.

- Regularly inspect and maintain equipment to prevent potential hazards.

- Establish clear emergency procedures and conduct regular safety drills.

- Foster a culture of safety awareness and encourage employees to report any concerns or hazards.

10. How do you measure and evaluate the performance of a candy production line?

- Track key performance indicators (KPIs) such as production output, efficiency, quality, and waste.

- Conduct regular audits and inspections to assess compliance with standards and procedures.

- Analyze production data to identify areas for improvement and optimization.

- Set performance targets and monitor progress towards goals.

- Provide feedback to production staff and collaborate on improvement initiatives.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Candy Puller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Candy Puller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Candy Pullers are responsible for making candy. They use a variety of machines to mix, cook, and form candy. They also package and store candy.

1. Operating Candy-Making Machines

Candy Pullers operate a variety of machines to make candy. These machines include candy cookers, candy mixers, and candy formers.

- Candy cookers are used to melt sugar and other ingredients to make candy.

- Candy mixers are used to mix the melted sugar with other ingredients, such as flavorings and colors.

- Candy formers are used to shape the candy into different shapes, such as balls, sticks, and bars.

2. Packaging and Storing Candy

Candy Pullers package and store candy to keep it fresh. They use a variety of packaging materials, such as cellophane, plastic wrap, and cardboard boxes.

- Candy Pullers package candy in individual pieces or in bulk.

- They also store candy in a cool, dry place to prevent it from spoiling.

3. Cleaning and Maintaining Equipment

Candy Pullers clean and maintain the equipment they use to make candy. They also clean the work area to prevent contamination.

- Candy Pullers clean equipment with soap and water.

- They also lubricate equipment to prevent it from breaking down.

4. Following Safety Procedures

Candy Pullers follow safety procedures to prevent accidents. They wear protective clothing and equipment, such as gloves and aprons.

- Candy Pullers also follow proper handling procedures for chemicals and equipment.

- They are aware of the potential hazards of working with hot liquids and machinery.

Interview Tips

To ace an interview for a Candy Puller position, you need to be prepared to answer questions about your experience, skills, and qualifications. You should also be able to demonstrate your knowledge of candy-making and safety procedures.

1. Research the Company and Position

Before you go on an interview, it is important to research the company and the position you are applying for. This will help you understand the company’s culture and the specific requirements of the job.

- Visit the company’s website to learn about their history, mission, and values.

- Read online reviews of the company to get a sense of what it is like to work there.

- Review the job description carefully so that you are familiar with the duties and responsibilities of the position.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is important to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

- Write down your answers to common interview questions and practice saying them out loud.

- Ask a friend or family member to give you mock interviews.

3. Be Yourself and Be Enthusiastic

The most important thing is to be yourself and be enthusiastic during your interview. The interviewer wants to get to know you and see if you are a good fit for the position. So be yourself, be confident, and show the interviewer why you are the best person for the job.

- Make eye contact with the interviewer and smile.

- Speak clearly and confidently.

- Be honest and authentic in your answers.

- Ask questions about the position and the company.

- Thank the interviewer for their time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Candy Puller interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.