Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Dough Cutter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

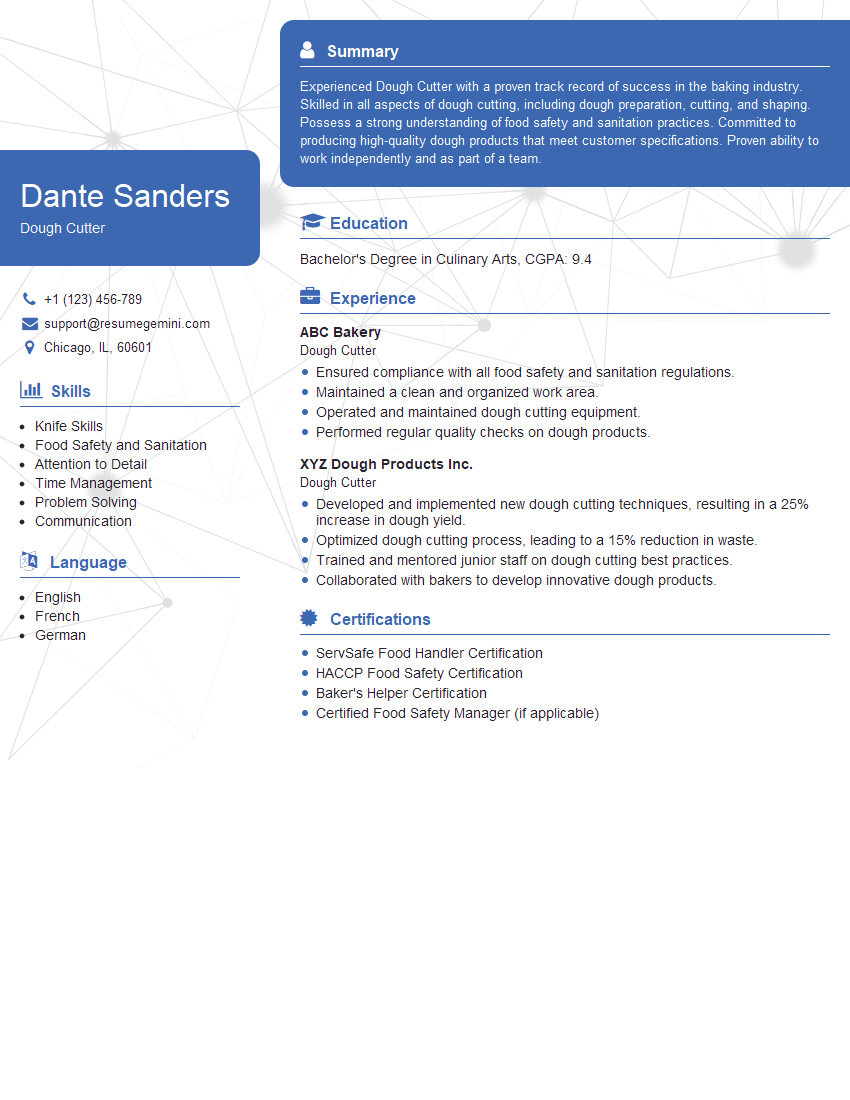

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dough Cutter

1. What are the essential characteristics of a high-quality dough, and how do you achieve them?

- Strong gluten network- this provides the dough with elasticity and strength, allowing it to rise properly and retain its shape during baking.

- Proper hydration- the right amount of water allows the gluten to develop properly and prevents the dough from becoming too dry or sticky.

- Correct temperature- the dough should be at the right temperature for the yeast to activate and ferment properly. Too cold and the yeast will not activate, too warm and it will die.

- Balanced ingredients- the flour, water, yeast, and salt must be balanced in the correct proportions to create a dough that is easy to work with and produces a high-quality finished product.

2. How do you troubleshoot common dough problems, such as stickiness, dryness, and poor elasticity?

Troubleshooting stickiness

- Add more flour, a little bit at a time, until the dough becomes less sticky.

- Knead the dough for a longer period of time to develop the gluten and make it less sticky.

- Let the dough rest for a period of time to allow the gluten to relax and make it less sticky.

Troubleshooting dryness

- Add more water, a little bit at a time, until the dough becomes less dry.

- Knead the dough for a shorter period of time to avoid overdeveloping the gluten and making the dough tough.

Troubleshooting poor elasticity

- Check the quality of the flour. Old or low-quality flour can produce dough with poor elasticity.

- Increase the amount of kneading time to develop the gluten and improve the elasticity of the dough.

- Add a small amount of vital wheat gluten to the dough to improve its elasticity.

3. What are the different types of dough used in baking, and what are their unique characteristics?

- Yeast dough– this is the most common type of dough, and it is used to make a variety of breads, rolls, and pastries. Yeast dough is made with flour, water, yeast, and salt, and it is allowed to rise before baking.

- Sourdough dough– this type of dough is made with a sourdough starter, which is a mixture of flour and water that has been fermented by wild yeast and bacteria. Sourdough dough has a unique sour flavor and a chewy texture.

- Phyllo dough– this type of dough is made with thin sheets of pastry dough that are rolled up and then cut into shapes. Phyllo dough is used to make a variety of pastries, such as baklava and spanakopita.

- Puff pastry– this type of dough is made with a combination of flour, water, butter, and salt. Puff pastry is rolled and folded several times to create a flaky texture.

4. How do you scale a dough recipe to adjust the yield?

- Determine the baker’s percentage of each ingredient in the original recipe.

- Multiply the baker’s percentage of each ingredient by the desired yield to determine the new amount of each ingredient.

- Check the new recipe to ensure that the proportions of the ingredients are balanced.

5. What are the food safety hazards associated with dough, and how can they be prevented?

- Bacteria– dough can be contaminated with bacteria from the flour, water, yeast, or other ingredients. Bacteria can cause food poisoning if ingested.

- Mold– dough can also be contaminated with mold, which can produce toxins that can cause illness.

- Food safety hazards can be prevented by following good manufacturing practices, such as:

- Using clean ingredients and equipment.

- Storing dough at the proper temperature.

- Cooking dough to the proper temperature.

6. What are the different techniques used to shape dough?

- Rounding– this is the process of shaping dough into a ball.

- Benching– this is the process of allowing dough to rest after it has been shaped.

- Proofing– this is the process of allowing dough to rise before baking.

- Scoring– this is the process of cutting designs into the surface of dough before baking.

7. What are the different types of ovens used for baking dough, and what are their unique advantages and disadvantages?

- Convection ovens– these ovens circulate hot air around the dough, which helps to cook it evenly and quickly.

- Deck ovens– these ovens have a stone or metal deck that the dough is baked on. Deck ovens produce a crispy crust and a chewy interior.

- Rotary ovens– these ovens rotate the dough as it bakes, which helps to cook it evenly.

8. How do you maintain and calibrate the equipment used in a dough production facility?

- Regular cleaning and maintenance– all equipment should be cleaned and maintained on a regular basis to prevent breakdowns and ensure optimal performance.

- Calibration– equipment should be calibrated regularly to ensure that it is measuring and dispensing ingredients accurately.

- Preventive maintenance– preventive maintenance can help to identify and fix potential problems before they cause a breakdown.

9. How do you train and supervise a team of dough production employees?

- Training– new employees should be trained on all aspects of dough production, including safety procedures, equipment operation, and quality control.

- Supervision– employees should be supervised on a regular basis to ensure that they are following procedures and meeting quality standards.

- Feedback– employees should be given regular feedback on their performance so that they can improve their skills and knowledge.

10. How do you stay up-to-date on the latest trends and technologies in dough production?

- Read trade publications– trade publications are a great way to stay up-to-date on the latest news and trends in the dough production industry.

- Attend industry events– industry events are a great way to learn about new technologies and meet with other professionals in the field.

- Take online courses– online courses are a convenient way to learn about new topics and improve your skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dough Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dough Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Dough Cutter is a crucial member of a bakery or food production team, responsible for cutting and preparing dough for various products.

1. Dough Preparation

Weigh, measure, and mix ingredients to create dough according to specified recipes.

2. Dough Rolling and Cutting

Roll out dough into desired shapes and sizes using a rolling pin or other equipment.

Cut dough into precise shapes and sizes using knives, dough cutters, or other tools.

3. Proofing and Maintenance

Proof dough at the correct temperature and humidity to allow it to rise and develop flavor.

Maintain clean and organized work areas to ensure dough quality and safety.

4. Equipment Maintenance and Safety

Clean and maintain equipment such as mixers, rolling pins, and cutters.

Follow safety protocols and wear appropriate safety gear to prevent accidents.

Interview Tips

Preparing for a Dough Cutter interview requires a combination of research, practice, and confidence. Here are some tips to help you ace the interview:

1. Research the Company and Position

Thoroughly review the job description and company website to understand the company’s culture, products, and expectations for the Dough Cutter role.

2. Practice Answering Common Interview Questions

Prepare answers to typical interview questions related to your skills, experience, and motivations. Consider using the STAR method to structure your responses effectively.

Example Outline:

- Situation: Describe a specific situation where you successfully cut and prepared dough in a professional setting.

- Task: Explain the task you were assigned and the specific techniques you used to roll out and cut the dough.

- Action: Clearly describe the actions you took to ensure the dough was cut accurately and consistently.

- Result: Highlight the positive outcome of your actions, emphasizing the quality and precision of the cut dough.

3. Highlight Your Skills and Experience

Emphasize your relevant skills, such as dexterity, precision, attention to detail, and knowledge of dough preparation techniques.

Quantify your accomplishments whenever possible to demonstrate your impact on previous roles.

4. Showcase Your Passion and Motivation

Explain your interest in becoming a Dough Cutter and why you are passionate about creating high-quality dough products.

Share any previous experiences or training that demonstrate your dedication to the craft.

5. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows your engagement and interest in the company and position.

Consider asking about the company’s growth plans, opportunities for professional development, or the specific challenges and rewards of being a Dough Cutter in their organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dough Cutter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!