Are you gearing up for an interview for a Liquid Sugar Fortifier position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Liquid Sugar Fortifier and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

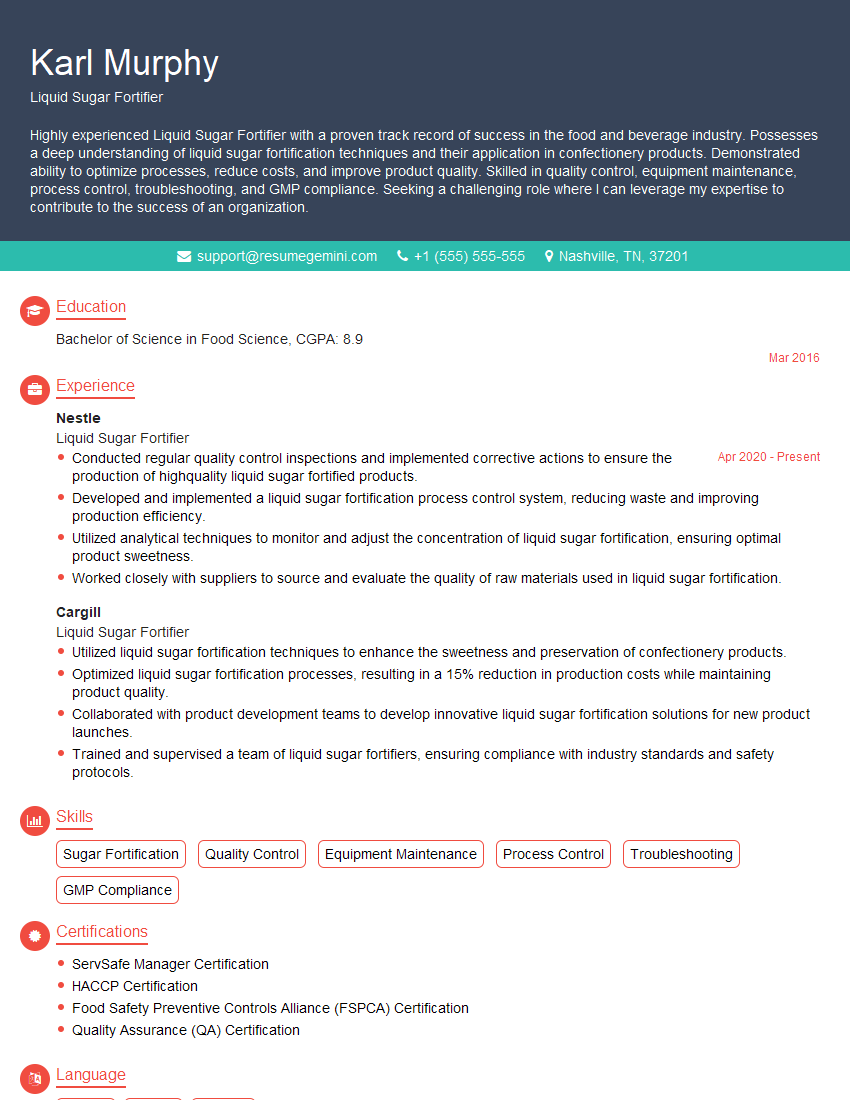

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Liquid Sugar Fortifier

1. Describe the process of fortifying liquid sugar, including the equipment used, key process parameters, and quality control measures.

Fortifying liquid sugar involves enhancing its nutritional content, typically with vitamins and minerals, to meet specific requirements. The process involves the following steps:

- Equipment: Mixing tanks, pumps, filters, and homogenizers are used for mixing, transferring, purifying, and blending the liquid sugar.

- Key process parameters: Temperature, pH, and concentration of fortifying agents are closely monitored and controlled to ensure proper mixing and stability.

- Quality control: Regular testing is performed to verify the concentration of fortifying agents, sugar content, and overall quality of the fortified liquid sugar.

2. Explain the role of different enzymes in the fortification process, including their sources, functions, and optimal conditions for activity.

α-Amylase

- Source: Microbial or plant-derived

- Function: Breaks down starch into smaller sugars, enhancing viscosity and sweetness

- Optimal conditions: pH 5.5-6.5, temperature 50-65°C

β-Amylase

- Source: Plant-derived

- Function: Converts starch into maltose, contributing to sweetness

- Optimal conditions: pH 5.0-5.5, temperature 40-50°C

Glucose isomerase

- Source: Microbial

- Function: Converts glucose into fructose, increasing sweetness

- Optimal conditions: pH 7.5-8.0, temperature 60-70°C

3. Discuss the various methods used to measure the concentration of fortifying agents in liquid sugar and compare their advantages and disadvantages.

- HPLC (High-Performance Liquid Chromatography): Accurate and specific, but requires expensive equipment and trained personnel.

- Spectrophotometry: Simple and cost-effective, but less precise than HPLC.

- Electrochemical sensors: Real-time monitoring, but may require calibration and maintenance.

- Colorimetric assays: Quick and easy, but limited in accuracy and specificity.

4. Describe the challenges associated with the storage and handling of fortified liquid sugar and how to mitigate these challenges.

- Microbial growth: Prevent by maintaining proper sanitation, using preservatives, and controlling temperature.

- Sugar crystallization: Avoid by controlling temperature, agitation, and storage conditions.

- Loss of fortification agents: Minimize by using stable compounds, protecting from light and heat, and conducting regular quality checks.

5. Explain the role of packaging in preserving the quality of fortified liquid sugar during transportation and storage.

- Barrier properties: Prevents moisture, oxygen, and light penetration.

- Chemical compatibility: Inert materials that do not react with the fortified sugar.

- Structural integrity: Protects the liquid sugar from physical damage.

- Labeling: Provides essential information about the product, including fortification levels and storage instructions.

6. Discuss the regulatory requirements and industry standards that govern the fortification of liquid sugar.

- Codex Alimentarius: International standards for food safety and quality.

- US Food and Drug Administration (FDA): Regulations for food additives and fortification levels.

- European Food Safety Authority (EFSA): Guidelines for vitamin and mineral fortification.

- Industry associations: Voluntary standards and best practices.

7. Describe the latest advancements in liquid sugar fortification technology and their potential benefits.

- Encapsulation techniques: Protects fortification agents from degradation.

- Nanotechnology: Enhanced bioavailability and targeted delivery.

- Biosynthesis: Production of fortification agents using microorganisms.

- Process optimization: Improved efficiency and reduced costs.

8. Explain the principles of good manufacturing practices (GMPs) as they apply to the fortification of liquid sugar.

- Sanitation and hygiene: Maintaining clean equipment and facilities.

- Quality control: Regular testing and monitoring to ensure product quality.

- Documentation: Accurate records of processes, ingredients, and testing.

- Personnel training: Providing employees with proper training and knowledge.

9. Describe the role of research and development in the continuous improvement of liquid sugar fortification practices.

- New fortification agents: Exploring novel vitamins, minerals, and prebiotics for fortification.

- Improved fortification techniques: Developing more efficient and cost-effective methods.

- Nutritional optimization: Formulating fortified liquid sugar products to meet specific dietary needs.

- Consumer preferences: Understanding consumer demands and preferences to develop innovative products.

10. Discuss the environmental and sustainability considerations involved in the production of fortified liquid sugar.

- Energy efficiency: Optimizing processes to reduce energy consumption.

- Waste reduction: Minimizing waste by-products and recycling materials.

- Sustainable sourcing: Ensuring responsible sourcing of raw materials, including sugar and fortification agents.

- Carbon footprint: Measuring and reducing the greenhouse gas emissions associated with production.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Liquid Sugar Fortifier.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Liquid Sugar Fortifier‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Liquid Sugar Fortifier is responsible for maintaining the quality of the liquid sugar used in the production process. The key responsibilities of the position include:

1. Fortifying Liquid Sugar

The primary responsibility of the Liquid Sugar Fortifier is to fortify the liquid sugar used in the production process. This involves adding the correct amount of fortifiers to the sugar, such as vitamins and minerals, to ensure that the final product meets the required nutritional standards.

- Determine the amount of fortifiers to add to the sugar based on the desired nutritional content of the final product.

- Add the fortifiers to the sugar in a safe and efficient manner, using appropriate equipment and techniques.

2. Monitoring Sugar Quality

The Liquid Sugar Fortifier is also responsible for monitoring the quality of the liquid sugar used in the production process. This involves conducting regular tests to ensure that the sugar meets the required specifications, such as Brix, pH, and color.

- Conduct tests on the liquid sugar to determine its Brix, pH, and color.

- Compare the results of the tests to the established specifications to ensure that the sugar meets the required standards.

3. Maintaining Equipment

The Liquid Sugar Fortifier is also responsible for maintaining the equipment used in the sugar fortification process. This involves cleaning and calibrating the equipment on a regular basis to ensure that it is functioning properly.

- Clean the equipment used in the sugar fortification process, including the sugar tanks, pumps, and pipelines.

- Calibrate the equipment used in the sugar fortification process to ensure that it is measuring and dispensing the correct amount of sugar and fortifiers.

4. Record Keeping

The Liquid Sugar Fortifier is also responsible for maintaining records of the sugar fortification process. This includes recording the amount of sugar and fortifiers used, the results of the quality tests, and any maintenance performed on the equipment.

- Maintain records of the sugar fortification process, including the amount of sugar and fortifiers used, the results of the quality tests, and any maintenance performed on the equipment.

- Keep accurate and up-to-date records to ensure that the sugar fortification process is being conducted in accordance with the established standards.

Interview Tips

In order to ace the interview for a Liquid Sugar Fortifier position, it is important to be well-prepared. Here are some tips to help you succeed:

1. Research the Position

Before the interview, it is important to research the position and the company. This will help you to understand the key responsibilities of the position and the company’s goals. You can research the company’s website, LinkedIn page, and Glassdoor reviews to gather information.

2. Practice Your Answers

Once you have researched the position, it is important to practice your answers to common interview questions. This will help you to feel more confident and prepared during the interview. You can practice your answers with a friend or family member, or you can use online resources such as YouTube videos or practice quizzes.

3. Dress Professionally

It is also important to dress professionally for the interview. This shows the interviewer that you are serious about the position and that you are making an effort to make a good impression.

4. Be Yourself

Finally, it is important to be yourself during the interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be honest and authentic, and let the interviewer see your personality.

Next Step:

Now that you’re armed with the knowledge of Liquid Sugar Fortifier interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Liquid Sugar Fortifier positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini