Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Melangeur Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

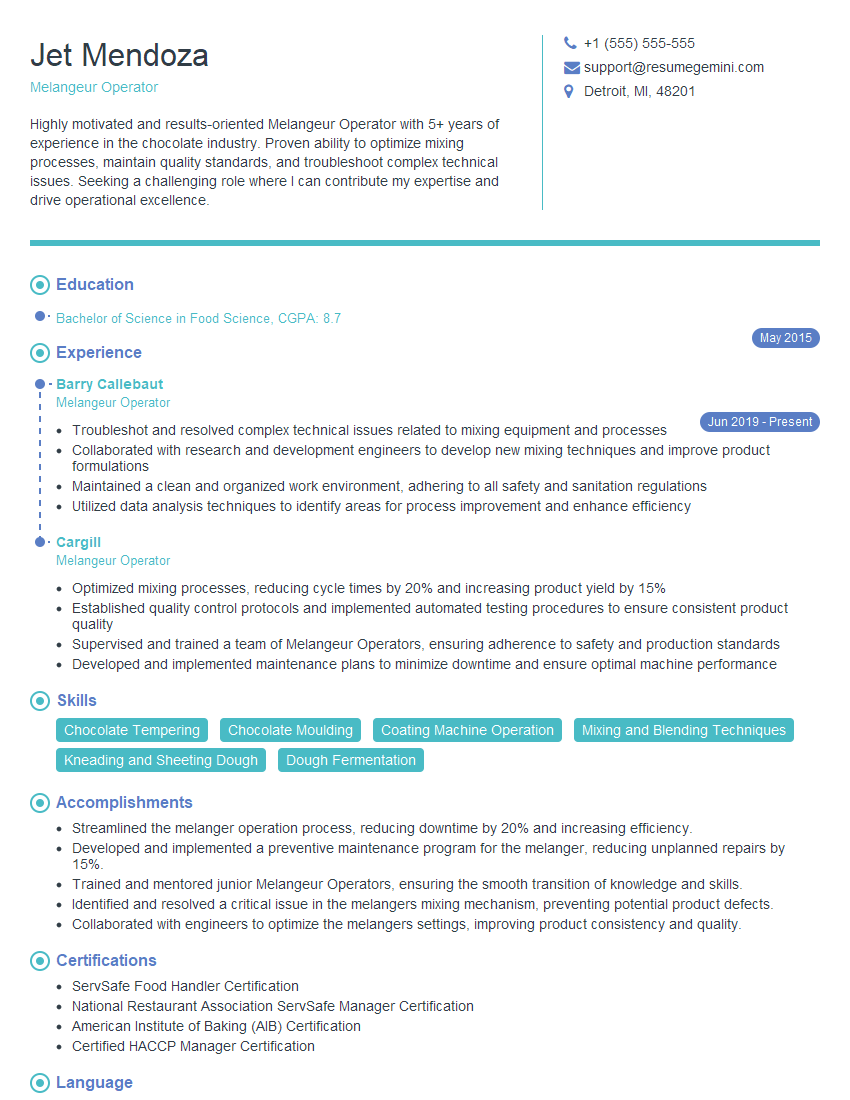

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Melangeur Operator

1. Describe the process of how a Melangeur machine operates?

A Melangeur machine is used to blend and mix various ingredients. The process of operation typically involves the following steps:

- Weighing and measuring the ingredients according to the recipe.

- Loading the ingredients into the Melangeur bowl.

- Setting the machine’s timer and temperature controls.

- Starting the machine and allowing it to mix the ingredients.

- Monitoring the mixing process to ensure that the desired consistency is achieved.

- Stopping the machine and discharging the blended mixture.

- Cleaning the Melangeur bowl and blades.

2. What are the different types of Melangeur machines available, and what are their key features and applications?

Batch Melangeurs

- Designed for small-scale production.

- Consist of a bowl that holds the ingredients and a rotating blade that mixes them.

- Suitable for mixing a wide range of materials, including chocolate, candy, and dough.

Continuous Melangeurs

- Designed for large-scale production.

- Feature a continuous flow of ingredients through the machine.

- Used for mixing high-volume products such as chocolate and peanut butter.

Planetary Melangeurs

- Similar to batch melangeurs, but have a rotating bowl that moves around a stationary blade.

- Provide more thorough mixing and can handle larger batches.

- Suitable for mixing a variety of materials, including chocolate, pastry dough, and meat.

3. What are the key factors to consider when selecting a Melangeur machine for a specific application?

When selecting a Melangeur machine, the following factors should be considered:

- The type of materials to be mixed.

- The desired consistency of the mixed product.

- The production volume required.

- The available space and budget.

4. How do you ensure the proper maintenance and calibration of a Melangeur machine?

To ensure proper maintenance and calibration of a Melangeur machine, the following steps should be taken:

- Regularly cleaning the machine, including the bowl, blades, and any other components that come into contact with the ingredients.

- Inspecting the machine for any worn or damaged parts and replacing them as necessary.

- Calibrating the machine’s timer and temperature controls to ensure accurate operation.

- Following the manufacturer’s instructions for maintenance and calibration procedures.

5. What are the safety precautions that must be observed when operating a Melangeur machine?

When operating a Melangeur machine, the following safety precautions should be observed:

- Wearing appropriate personal protective equipment, such as gloves and safety glasses.

- Ensuring that the machine is properly grounded and that all electrical connections are secure.

- Never reaching into the machine while it is operating.

- Keeping the work area clean and free of any potential hazards.

- Following all manufacturer’s instructions for safe operation.

6. Describe the different types of mixing blades used in Melangeur machines and their specific applications?

Paddle Blades

- Used for general mixing purposes.

- Suitable for mixing a wide range of materials.

Scraper Blades

- Used for scraping the sides of the bowl and preventing ingredients from sticking.

- Suitable for mixing thick or sticky materials.

Kneading Blades

- Used for kneading dough and other elastic materials.

- Provide a more intense mixing action.

Emulsifying Blades

- Used for creating emulsions, such as mayonnaise and salad dressings.

- Feature a high-speed rotation that breaks down and disperses ingredients.

7. How do you troubleshoot common problems that may occur during the operation of a Melangeur machine?

Some common problems that may occur during the operation of a Melangeur machine and their troubleshooting steps include:

- Problem: Machine not mixing properly.

- Troubleshooting: Check the blade assembly for damage or wear. Ensure that the machine is properly calibrated.

- Problem: Motor overheating.

- Troubleshooting: Check the electrical connections and ensure that the machine is not overloaded.

- Problem: Ingredients sticking to the bowl.

- Troubleshooting: Use a scraper blade or adjust the mixing speed.

8. What are the different methods used for controlling the temperature of the mixture in a Melangeur machine?

The temperature of the mixture in a Melangeur machine can be controlled using the following methods:

- Water Jackets: The bowl of the machine is surrounded by a jacket through which cold or hot water circulates to maintain the desired temperature.

- Heated Blades: The blades of the machine are heated to raise the temperature of the mixture.

- Temperature Sensors: The machine is equipped with temperature sensors that monitor the temperature of the mixture and adjust the heating or cooling system accordingly.

9. What are the advantages and disadvantages of using a Melangeur machine for mixing ingredients?

Advantages:

- Thorough and efficient mixing.

- Capable of handling a wide range of materials.

- Can be used for both small and large production batches.

- Versatile and can be used for a variety of applications.

Disadvantages:

- Can be expensive to purchase and maintain.

- Requires skilled operators to achieve optimal results.

- Can be noisy during operation.

10. Describe the different types of materials that can be processed using a Melangeur machine?

A Melangeur machine can be used to process a wide range of materials, including:

- Chocolate

- Candy

- Dough

- Meat

- Nuts

- Cosmetics

- Pharmaceuticals

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Melangeur Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Melangeur Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Melangeur Operator is responsible for operating a melangeur machine, which is used to mix and blend raw materials for the production of rubber compounds. The key job responsibilities of a Melangeur Operator include:

1. Operating the Melangeur Machine

The Melangeur Operator is responsible for operating the melangeur machine in accordance with established procedures. This involves loading the raw materials into the machine, setting the machine parameters, and monitoring the mixing process to ensure that the desired results are achieved.

- Loading the raw materials into the melangeur machine

- Setting the machine parameters, such as temperature, speed, and mixing time

- Monitoring the mixing process to ensure that the desired results are achieved

2. Maintaining the Melangeur Machine

The Melangeur Operator is also responsible for maintaining the melangeur machine in good working order. This involves cleaning the machine, lubricating the moving parts, and performing minor repairs as needed.

- Cleaning the melangeur machine

- Lubricating the moving parts

- Performing minor repairs as needed

3. Inspecting the Raw Materials

Before loading the raw materials into the melangeur machine, the Melangeur Operator must inspect them to ensure that they are of the correct quality and quantity. This involves visually inspecting the materials for any defects or contamination, and weighing the materials to ensure that the correct amount is used.

- Visually inspecting the raw materials for any defects or contamination

- Weighing the materials to ensure that the correct amount is used

4. Keeping Records

The Melangeur Operator is responsible for keeping records of the mixing process, including the raw materials used, the machine parameters, and the results achieved. These records must be accurate and complete, as they are used to ensure the quality of the rubber compounds produced.

- Keeping records of the raw materials used

- Keeping records of the machine parameters

- Keeping records of the results achieved

Interview Tips

Here are some tips to help you ace your interview for a Melangeur Operator position:

1. Research the Company and the Position

Before you go to your interview, take the time to research the company and the position you are applying for. This will help you to understand the company’s culture and values, and the specific requirements of the position. This will also show the interviewer that you are interested in the position and that you have taken the time to prepare for the interview.

- Visit the company’s website

- Read articles about the company in the news

- Talk to people who work for the company

- Review the job description carefully

- Make a list of your skills and experience that are relevant to the position

2. Be on Time for Your Interview

Punctuality is important for any job interview, but it is especially important for a Melangeur Operator position. This is because the Melangeur Operator is responsible for operating a machine that can be dangerous if not operated properly. Being on time for your interview shows the interviewer that you are reliable and that you take your job seriously.

- Plan your route to the interview in advance

- Leave early to give yourself plenty of time

- If you are running late, call the interviewer to let them know

3. Dress Appropriately

The way you dress for your interview will say a lot about you. For a Melangeur Operator position, it is important to dress professionally. This means wearing clean, pressed clothes that cover your body appropriately. You should also avoid wearing jewelry or accessories that could get caught in the machine.

- Wear a button-down shirt or blouse

- Wear khakis or dress pants

- Wear closed-toe shoes

- Avoid wearing jewelry or accessories that could get caught in the machine

4. Be Prepared to Answer Questions

The interviewer will likely ask you a variety of questions during your interview. Some of these questions will be about your skills and experience, while others will be about your personality and work ethic. It is important to be prepared to answer these questions in a clear and concise manner. The more prepared you are, the more confident you will be during your interview.

- Practice answering common interview questions

- Research the company and the position so that you can answer questions about them

- Be prepared to talk about your skills and experience

- Be prepared to talk about your personality and work ethic

5. Ask Questions

At the end of your interview, the interviewer will likely ask you if you have any questions. This is your opportunity to learn more about the company and the position, and to show the interviewer that you are interested in the job. Be sure to ask thoughtful questions that show that you have done your research. This will leave a lasting impression on the interviewer and will increase your chances of getting the job.

- Ask about the company’s culture and values

- Ask about the specific requirements of the position

- Ask about the company’s plans for the future

- Ask about the interviewer’s experience with the company

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Melangeur Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!