Feeling lost in a sea of interview questions? Landed that dream interview for Mixing Tank Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Mixing Tank Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

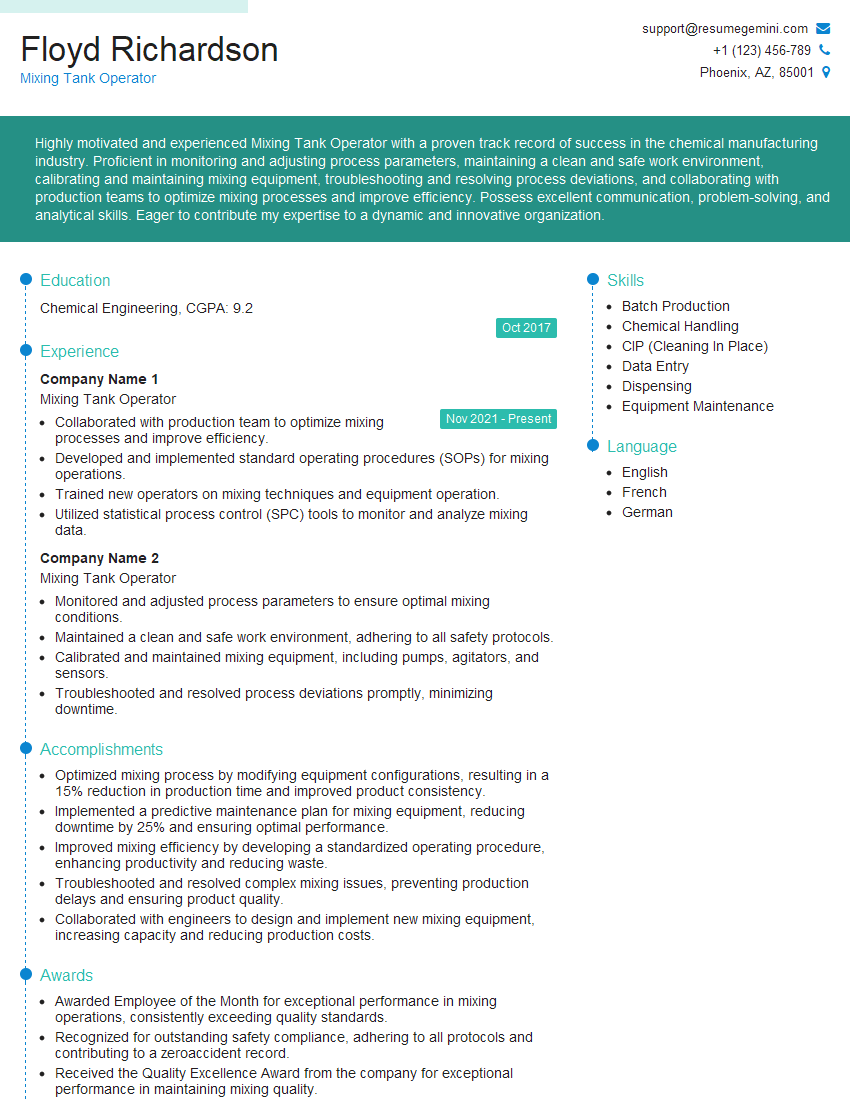

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mixing Tank Operator

1. What are the primary responsibilities of a Mixing Tank Operator?

As a Mixing Tank Operator, my key responsibilities would include:

- Operating and monitoring mixing tanks to ensure proper blending of ingredients according to specified formulations.

- Maintaining and calibrating mixing equipment, including tanks, agitators, and pumps, to ensure optimal performance.

- Performing quality control checks on mixed products to verify adherence to specifications.

- Following established safety protocols and adhering to industry best practices.

- Monitoring and maintaining inventory levels of raw materials and finished products.

- Working effectively with production and quality control teams to ensure smooth operation.

- Keeping accurate records of production and maintenance activities.

2. Explain the importance of maintaining accurate temperature and agitation levels in mixing tanks.

Benefits of Maintaining Accurate Temperature:

- Ensures desired chemical reactions and product quality.

- Prevents product degradation or contamination.

- Optimizes mixing efficiency and reduces production time.

Benefits of Maintaining Proper Agitation:

- Creates a homogeneous mixture, ensuring consistent product quality.

- Prevents settling or separation of ingredients.

- Reduces the risk of product defects or imperfections.

3. How do you ensure the proper cleaning and sanitation of mixing tanks to prevent contamination?

To ensure proper cleaning and sanitation, I follow a rigorous protocol:

- Thoroughly rinsing the tank with water to remove any residual product.

- Using appropriate cleaning agents and following specific cleaning procedures to eliminate contaminants.

- Sanitizing the tank with approved disinfectants to kill bacteria and microorganisms.

- Inspecting the tank to verify that it meets cleanliness standards.

- Following established SOPs (Standard Operating Procedures) for cleaning and sanitation.

4. Describe the different types of mixing equipment used in a production facility and their specific applications.

- Paddle mixers: Used for blending solids or liquids with low to medium viscosity.

- Ribbon mixers: Ideal for mixing dry powders and granules, providing gentle agitation to prevent particle damage.

- Turbine mixers: Used for high-shear mixing applications, dispersing solids in liquids or creating emulsions.

- Propeller mixers: Suitable for agitating liquids with high flow rates, providing axial mixing.

- Homogenizers: Used for creating fine emulsions and dispersions, breaking down particles to nanoscale.

5. Explain the safety precautions you observe when operating mixing tanks, including the use of personal protective equipment (PPE).

I prioritize safety by adhering to established protocols and utilizing appropriate PPE:

- Wearing protective clothing, including flame-retardant coveralls, safety glasses, gloves, and a hard hat.

- Using respiratory protection if handling hazardous chemicals.

- Following lockout/tagout procedures when performing maintenance or repairs.

- Maintaining a clean and organized work area to minimize tripping hazards.

- Being aware of potential hazards, such as spills, leaks, or electrical risks.

6. How do you troubleshoot common problems that may arise during mixing operations, such as uneven mixing or equipment malfunctions?

To troubleshoot common problems, I follow a systematic approach:

- Uneven mixing: Check agitator speed, blade alignment, and ingredient proportions.

- Equipment malfunction: Inspect electrical connections, belts, and bearings. Consult maintenance personnel if necessary.

- Clogging or blockages: Inspect nozzles, pumps, and filters for any obstructions.

- Leaks or spills: Identify the source of the leak and immediately contain it using appropriate measures.

- Temperature deviations: Check temperature sensors, heating or cooling systems, and insulation.

7. Describe the role of monitoring and record-keeping in ensuring the efficiency and quality of mixing operations.

Monitoring and record-keeping are crucial for:

- Ensuring consistent product quality: By tracking temperature, agitation, and ingredient ratios.

- Identifying areas for improvement: Analyzing data to optimize mixing parameters and reduce waste.

- Maintaining compliance with regulations: Adhering to established quality control standards and industry best practices.

- Providing evidence for auditing purposes: Documenting activities to demonstrate adherence to procedures.

- Facilitating knowledge transfer: Sharing records with colleagues to promote best practices and ensure continuity.

8. Explain how you collaborate with other departments, such as production and quality control, to ensure seamless mixing operations.

Effective collaboration is essential:

- Production: Coordinating production schedules, ensuring timely delivery of mixed products.

- Quality control: Providing samples for testing, receiving feedback on product quality, and implementing corrective actions.

- Maintenance: Reporting equipment issues, scheduling maintenance, and ensuring equipment reliability.

- Research and development: Testing new formulations and optimizing mixing processes for improved efficiency.

- Health and safety: Adhering to safety protocols, reporting hazards, and participating in safety training.

9. Describe your experience in using automated control systems for mixing operations, including programming and troubleshooting.

I have experience in operating and troubleshooting automated control systems:

- Programming: Configuring parameters, recipes, and safety interlocks.

- Troubleshooting: Identifying and resolving issues with sensors, actuators, and software.

- Calibration: Ensuring accuracy and reliability of measurement instruments.

- Maintenance: Performing routine maintenance tasks to prevent breakdowns.

- Data analysis: Interpreting data from control systems to identify trends and areas for improvement.

10. How do you stay updated with the latest advancements in mixing technology and best practices?

I prioritize continuous learning:

- Attending industry conferences and workshops: Gaining knowledge about new technologies and industry trends.

- Reading technical journals and articles: Keeping abreast of research and best practices.

- Participating in online forums and discussions: Connecting with other professionals and sharing knowledge.

- Seeking guidance from mentors and experts: Learning from experienced individuals in the field.

- Exploring vendor resources: Staying informed about product updates and advancements.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mixing Tank Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mixing Tank Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mixing Tank Operators play a crucial role in maintaining a safe and efficient work environment within chemical processing plants and other industrial settings. Their primary responsibilities involve monitoring and operating mixing tanks, ensuring that the blending process aligns with established specifications and quality standards. Here are some key job responsibilities of a Mixing Tank Operator:

1. Monitoring and Controlling Mixing Process

Mixing Tank Operators are responsible for overseeing the mixing process, ensuring that the desired blend of materials is achieved. This involves:

- Receiving and interpreting work orders, blueprints, and process specifications

- Setting up mixing tanks and selecting appropriate mixing equipment

- Loading raw materials into the mixing tank and adjusting ingredient ratios

- Initiating and monitoring the mixing process, adjusting variables such as temperature, speed, and duration

- Collecting samples for quality control testing and making necessary adjustments to the mixing process based on test results

- Maintaining accurate records of all mixing operations, including materials used, process parameters, and quality control data

2. Equipment Maintenance and Troubleshooting

Mixing Tank Operators are responsible for ensuring that equipment is operating smoothly and efficiently. This involves:

- Performing regular maintenance on mixing tanks, pumps, and other associated equipment

- Identifying and troubleshooting equipment malfunctions

- Coordinating with maintenance personnel for repairs and replacements

- Ensuring that all equipment is in compliance with safety regulations and industry standards

3. Adherence to Safety Protocols

Safety is paramount in the role of a Mixing Tank Operator. They are responsible for:

- Adhering to all established safety protocols and regulations

- Wearing appropriate personal protective equipment (PPE) at all times

- Following proper lockout/tagout procedures

- Handling hazardous materials with utmost care and following proper disposal procedures

- Maintaining a clean and organized work area

- Reporting any accidents, spills, or other safety concerns promptly and accurately

4. Communication and Teamwork

Mixing Tank Operators often work as part of a team. They are responsible for communicating effectively with:

- Supervisors and managers

- Quality control personnel

- Maintenance technicians

- Co-workers

- Customers or clients (if applicable)

Effective communication ensures smooth operation, coordination of tasks, and timely problem-solving.

Interview Tips

Preparing for a Mixing Tank Operator interview requires a combination of technical knowledge, safety awareness, and a commitment to teamwork. Here are some tips to help you ace the interview:

1. Research the Company and Role

Before the interview, take the time to research the company, their industry, and the specific role you are applying for. This will help you understand the company culture, their business objectives, and the key responsibilities of the Mixing Tank Operator position. You can find this information on the company website, industry publications, or through networking.

2. Practice Answering Common Interview Questions

There are certain common interview questions that you are likely to encounter during a Mixing Tank Operator interview. Prepare your responses to these questions in advance. Some examples include:

- “Tell me about your experience in operating mixing tanks and related equipment.”

- “Describe your knowledge of safety protocols and regulations in a chemical processing environment.”

- “How do you handle troubleshooting and problem-solving in a fast-paced production setting?”

- “What is your approach to working as part of a team and communicating effectively with others?”

- “Why are you interested in this position and how do your skills align with the job requirements?”

3. Highlight Your Skills and Experience

Make sure to highlight your relevant skills and experience during the interview. Quantify your accomplishments whenever possible, using specific examples to demonstrate your abilities. For instance, you could mention the number of mixing tanks you have operated, the types of materials you have worked with, or any specific safety improvements you have implemented.

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. Prepare a few questions that demonstrate your understanding of the role and the company. This could include questions about the company’s growth plans, their commitment to safety, or any specific challenges the Mixing Tank Operator may face.

5. Be Professional and Enthusiastic

First impressions matter, so make sure to dress professionally and arrive for your interview on time. Maintain a positive and enthusiastic attitude throughout the interview, as this will convey your interest in the position and your commitment to the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mixing Tank Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.