Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pickling Solution Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

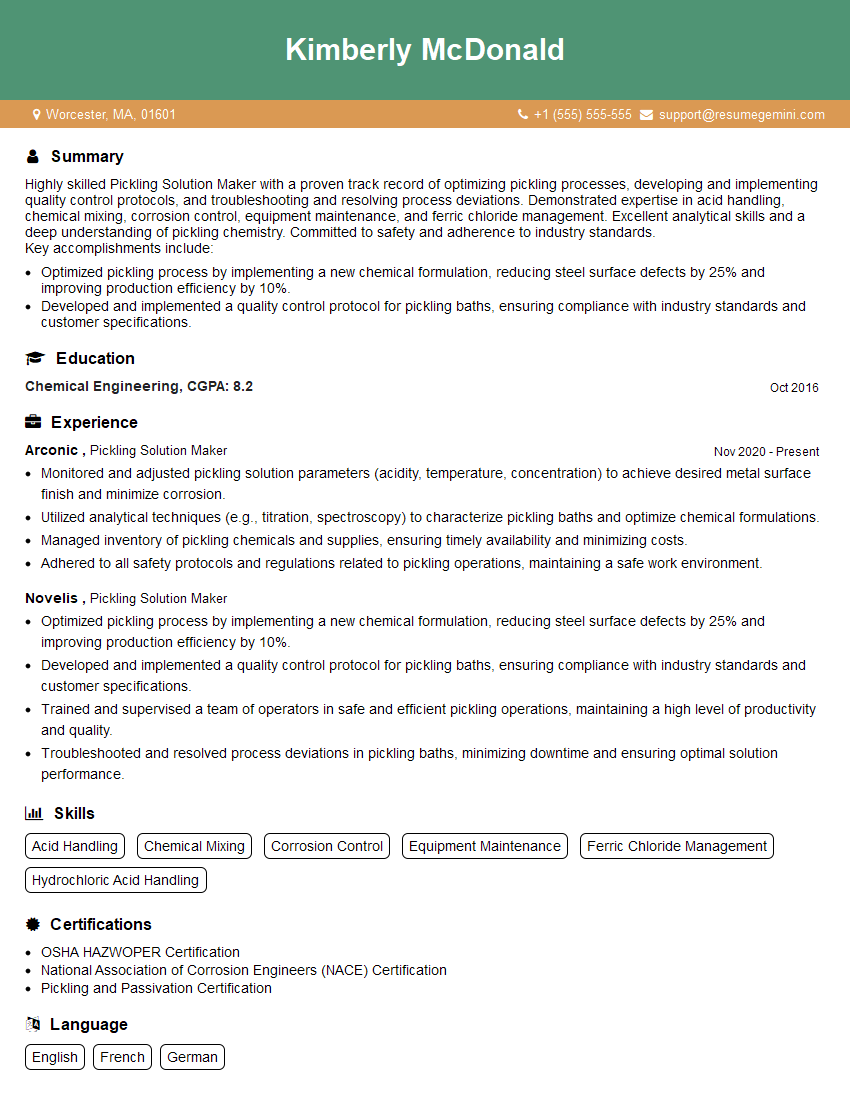

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pickling Solution Maker

1. Explain the process of pickling and the role of pickling solutions?

Pickling is a metal surface treatment process that removes rust, scale, and other contaminants to prepare the metal for further processing such as painting, plating, or welding. Pickling solutions are typically acidic and contain ingredients like hydrochloric acid, sulfuric acid, or nitric acid.

- The pickling process involves immersing the metal in the pickling solution for a period of time, which dissolves the rust and scale.

- The pickling solution is then rinsed off the metal, and the metal is dried and prepared for further processing.

2. What are the different types of pickling solutions and their applications?

Types of Pickling Solutions

- Hydrochloric Acid Based: Used for pickling steel and iron; removes rust and scale efficiently.

- Sulfuric Acid Based: Suitable for pickling stainless steel; also used as a general-purpose pickling solution.

- Nitric Acid Based: Commonly used for pickling aluminum and copper alloys; creates a passive layer on the metal surface.

Applications

- Pre-plating treatment for automotive parts, electronic components, and construction materials.

- Removing corrosion and rust from metal surfaces in industries such as shipbuilding and oil and gas.

- Etching and surface preparation for printing, engraving, and metalworking.

3. How do you determine the right pickling solution and concentration for a specific metal?

The selection of the pickling solution and its concentration depends on several factors:

- Metal Type: Different metals have different reactivity with acids.

- Contaminants: The type and amount of rust, scale, or other contaminants on the metal.

- Desired Result: Whether a light or heavy pickled finish is required.

- Safety and Environmental Regulations: Consider the toxicity and disposal requirements of different pickling solutions.

Referencing technical data sheets, consulting with chemical suppliers, or conducting trial tests can help determine the optimal pickling solution and concentration.

4. How do you monitor and control the pickling process to ensure product quality?

- Solution Strength: Regularly measure the acid concentration using titration or pH probes.

- Temperature: Monitor and adjust the temperature of the solution as it affects pickling rate and surface finish.

- Immersion Time: Control the duration of metal immersion to achieve the desired level of pickling.

- Agitation: Ensure proper mixing and agitation of the solution to facilitate uniform pickling.

- Surface Inspection: Regularly inspect the pickled metal for any defects or inconsistencies.

5. What are the safety precautions and environmental regulations that need to be followed when working with pickling solutions?

-

Safety Precautions:

- Wear appropriate personal protective equipment (PPE) such as gloves, goggles, and respirators.

- Handle acids with care, avoid contact with skin and eyes, and follow proper spill containment procedures.

- Ensure adequate ventilation in the workspace to prevent exposure to fumes. Environmental Regulations:

- Dispose of spent pickling solutions and rinse water in accordance with local regulations.

- Neutralize acidic waste before disposal to minimize environmental impact.

- Comply with industry standards and best practices for waste management.

6. Describe the different methods used to prepare and store pickling solutions?

Preparation Methods

- Dilution: Diluting concentrated acids with water to achieve the desired concentration.

- Inhibition: Adding inhibitors to prevent excessive metal loss and improve pickling efficiency.

Storage Methods

- Tanks: Store solutions in corrosion-resistant tanks made of materials like polyethylene or fiberglass.

- Drums: Use heavy-duty plastic or metal drums for smaller volumes.

- Proper Ventilation: Ensure adequate ventilation around storage areas to prevent fume buildup.

7. Explain the role of inhibitors in pickling solutions and how they affect the pickling process?

Inhibitors are chemical additives that reduce the rate of metal dissolution during pickling and improve surface finish:

- Reduced Metal Loss: Inhibitors create a protective layer on the metal surface, minimizing unnecessary etching.

- Improved Surface Finish: They help prevent pitting and uneven pickling, resulting in a smoother and more uniform surface.

- Extended Solution Life: Inhibitors slow down the pickling reaction, prolonging the life of the pickling solution.

8. Discuss the factors that influence the pickling rate and how to optimize it?

- Solution Concentration: Higher acid concentrations generally increase pickling rate.

- Temperature: Elevated temperatures accelerate the pickling process.

- Agitation: Proper agitation ensures uniform contact between the solution and metal surface, enhancing pickling rate.

- Metal Type and Condition: Different metals have varying reactivity with acids, and the presence of contaminants can affect pickling rate.

- Inhibitor Concentration: Optimizing inhibitor concentration balances pickling rate with surface finish requirements.

9. Describe the equipment used in a pickling line and their functions?

- Tanks: Hold the pickling solution and the metal being pickled.

- Conveyors: Transport metal parts through the pickling line.

- Rinsing Equipment: Used to rinse the metal after pickling to remove residual acid.

- Dryers: Remove moisture from the metal after rinsing.

- Fume Scrubbers: Control and remove fumes generated during pickling.

10. What are the challenges in pickling and how can they be overcome?

- Excessive Metal Loss: Optimize pickling parameters and use inhibitors to minimize unnecessary etching.

- Surface Defects: Control pickling conditions, such as temperature and agitation, to prevent pitting and uneven pickling.

- Hydrogen Embrittlement: Use proper pickling practices and post-pickling treatments to avoid hydrogen absorption by the metal.

- Waste Disposal: Implement proper waste management practices to comply with environmental regulations.

- Safety Hazards: Ensure adequate ventilation, wear appropriate PPE, and follow safety protocols to mitigate risks associated with handling acids.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pickling Solution Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pickling Solution Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Pickling Solution Maker is responsible for overseeing the preparation and maintenance of pickling solutions used in the metalworking industry.

1. Solution Preparation

- Measure and mix chemicals according to specified formulas to create pickling solutions.

- Monitor solution concentration using titration equipment to ensure it meets required specifications.

2. Solution Maintenance

- Regularly monitor solution composition and make necessary adjustments to maintain optimal pickling performance.

- Conduct chemical and physical tests on solutions to identify any potential issues.

- Filter and replace spent solutions to ensure consistent solution quality.

3. Equipment Operation

- Operate and maintain pickling equipment, including tanks, pumps, and mixing systems.

- Clean and inspect equipment regularly to ensure proper functionality.

4. Safety and Environmental Compliance

- Follow all safety procedures and wear appropriate protective gear.

- Handle and dispose of chemicals safely and in accordance with environmental regulations.

Interview Tips

To ace an interview for a Pickling Solution Maker position, it’s essential to demonstrate your technical knowledge and understanding of the role.

1. Research the Industry

- Familiarize yourself with the metalworking industry and the specific applications of pickling solutions.

- Understand the different types of pickling processes and the role of pickling solutions in each.

2. Highlight Your Experience

- Emphasize your experience in preparing and maintaining pickling solutions.

- Provide specific examples of your work and the results you achieved.

3. Demonstrate Your Technical Skills

- Show your understanding of chemical formulas and titration techniques.

- Discuss your experience in operating pickling equipment and troubleshooting any issues.

4. Emphasize Your Safety Awareness

- Discuss your experience in handling and disposing of chemicals safely.

- Explain your understanding of relevant safety regulations and your commitment to following them.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pickling Solution Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!