Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Dextrine Mixer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

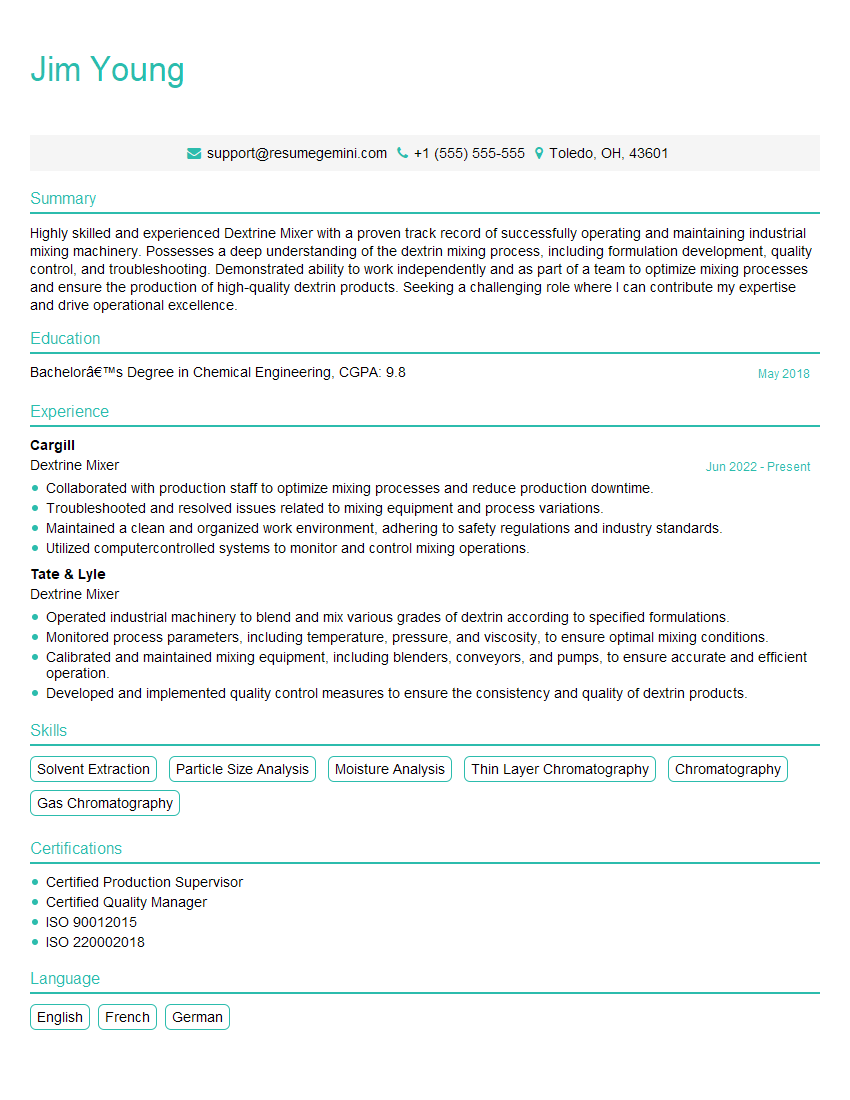

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dextrine Mixer

1. Describe the process of dextrinization in detail.

Dextrinization is the process of breaking down starch into smaller molecules, called dextrins. This can be done through the use of heat, acid, or enzymes. The degree of dextrinization can vary, depending on the desired end product.

- The first step in dextrinization is to gelatinize the starch. This involves heating the starch in water until it reaches a temperature of around 60°C (140°F). At this point, the starch granules will swell and burst, releasing their contents.

- Once the starch has been gelatinized, it can be broken down into dextrins using a variety of methods. One method is to use heat. When starch is heated to a high temperature, it will break down into smaller molecules. Another method is to use acid. Acid can also break down starch into dextrins. Finally, starch can be broken down into dextrins using enzymes. Enzymes are biological catalysts that can speed up the rate of chemical reactions. There are a number of different enzymes that can be used to break down starch into dextrins.

- The degree of dextrinization can be controlled by varying the temperature, pH, and time of the reaction. The higher the temperature, the more acidic the pH, and the longer the time of the reaction, the greater the degree of dextrinization.

2. What are the different types of dextrins?

- There are three main types of dextrins: white dextrin, yellow dextrin, and British gum.

- White dextrin is a white powder that is soluble in water. It is used as a thickener in a variety of food products, such as soups, sauces, and gravies.

- Yellow dextrin is a yellow powder that is soluble in water. It is used as a binder in a variety of food products, such as bread, cookies, and crackers.

- British gum is a brown powder that is soluble in water. It is used as an adhesive in a variety of products, such as paper, textiles, and wood.

3. How is dextrin used in the food industry?

- Dextrin is used in the food industry as a thickener, binder, and adhesive.

- As a thickener, dextrin is used to increase the viscosity of food products. This makes them thicker and more creamy.

- As a binder, dextrin is used to hold food products together. This makes them less likely to crumble or break apart.

- As an adhesive, dextrin is used to stick food products together. This makes them easier to handle and package.

4. How is dextrin used in the paper industry?

- Dextrin is used in the paper industry as a coating and adhesive.

- As a coating, dextrin is used to give paper a glossy finish. This makes it more resistant to water and wear.

- As an adhesive, dextrin is used to bind paper fibers together. This makes paper stronger and more durable.

5. How is dextrin used in the textile industry?

- Dextrin is used in the textile industry as a sizing agent and adhesive.

- As a sizing agent, dextrin is used to give textiles a stiff finish. This makes them more resistant to wrinkles and wear.

- As an adhesive, dextrin is used to bind textiles together. This makes them stronger and more durable.

6. What are the safety considerations for working with dextrin?

- Dextrin is a combustible dust. This means that it can easily catch fire and explode.

- Dextrin can also cause skin and eye irritation. It is important to wear gloves and eye protection when working with dextrin.

- Dextrin should be stored in a cool, dry place. It should not be exposed to heat or moisture.

7. What are the environmental considerations for working with dextrin?

- Dextrin is a biodegradable material. This means that it can be broken down by bacteria and other microorganisms.

- Dextrin can be released into the environment through wastewater and solid waste. It is important to properly dispose of dextrin to avoid environmental contamination.

8. What are the current trends in dextrin production and use?

- The demand for dextrin is increasing due to its use in a variety of industries.

- There is a growing trend towards using dextrin from renewable resources, such as corn and wheat.

- There is also a growing trend towards using dextrin in more sustainable ways, such as using it as a biodegradable material.

9. What are the future prospects for dextrin?

- The future prospects for dextrin are positive.

- The demand for dextrin is expected to continue to grow due to its versatility and sustainability.

- Dextrin is a promising material for a variety of applications, including food, paper, textiles, and adhesives.

10. What are your qualifications for this position?

I have a Bachelor of Science degree in Chemical Engineering from the University of Illinois at Urbana-Champaign. I have also worked as a Dextrin Mixer for the past five years at a large food processing company. In this role, I was responsible for the operation and maintenance of the dextrin mixing equipment. I also developed and implemented new methods for improving the efficiency of the dextrin mixing process.

- I am a highly motivated and results-oriented individual with a strong work ethic.

- I am also a team player with excellent communication and interpersonal skills.

- I am confident that I have the skills and experience necessary to be successful in this position.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dextrine Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dextrine Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Dextrine Mixers play a crucial role in the manufacturing process by following detailed recipes and operating specialized mixing equipment. They are responsible for ensuring the precise blending of raw materials and additives to produce dextrin, a modified starch used in various industries such as food, pharmaceuticals, and adhesives.

1. Raw Material Handling

Dextrine Mixers are responsible for receiving and inspecting raw materials such as starch, water, and chemicals. They ensure that the materials meet quality standards and specifications before being added to the mixing process.

2. Mixing and Processing

Dextrine Mixers operate and monitor mixing equipment to blend raw materials according to precise recipes. They adjust and control mixing parameters such as temperature, pressure, and mixing time to achieve desired dextrin properties.

3. Quality Control and Analysis

Dextrine Mixers conduct quality control checks at various stages of the mixing process. They perform laboratory tests and analyze samples to ensure that the dextrin meets specifications and customer requirements.

4. Equipment Maintenance and Troubleshooting

Dextrine Mixers are responsible for maintaining and troubleshooting mixing equipment. They identify and resolve issues to ensure smooth operation and prevent downtime.

Interview Tips

To ace an interview for a Dextrine Mixer position, candidates should prepare thoroughly by researching the role and the company. Here are some tips to help them succeed:

1. Research the Company and Industry

Candidates should thoroughly research the company and the dextrin industry to understand their business operations, products, and competitive landscape. This knowledge will help them demonstrate their understanding of the role and the company’s needs.

2. Practice Technical Skills

Candidates should brush up on their technical skills related to mixing and processing. They should be familiar with different types of mixing equipment, blending techniques, and quality control procedures.

3. Highlight Relevant Experience and Skills

Candidates should emphasize their relevant experience in the manufacturing or food processing industry. They should highlight their abilities in raw material handling, mixing and processing, quality control, and equipment maintenance.

4. Prepare for Common Interview Questions

Common interview questions for Dextrine Mixers include:

- Describe your experience in mixing and processing dextrin.

- How do you ensure the quality and consistency of dextrin products?

- What types of mixing equipment are you familiar with?

- How do you troubleshoot and resolve issues with mixing equipment?

5. Ask Insightful Questions

Candidates should ask thoughtful questions during the interview to demonstrate their engagement and interest in the role. This could include questions about the company’s growth plans, the role’s responsibilities, or the opportunities for professional development.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dextrine Mixer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!