Are you gearing up for an interview for a Retort Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Retort Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

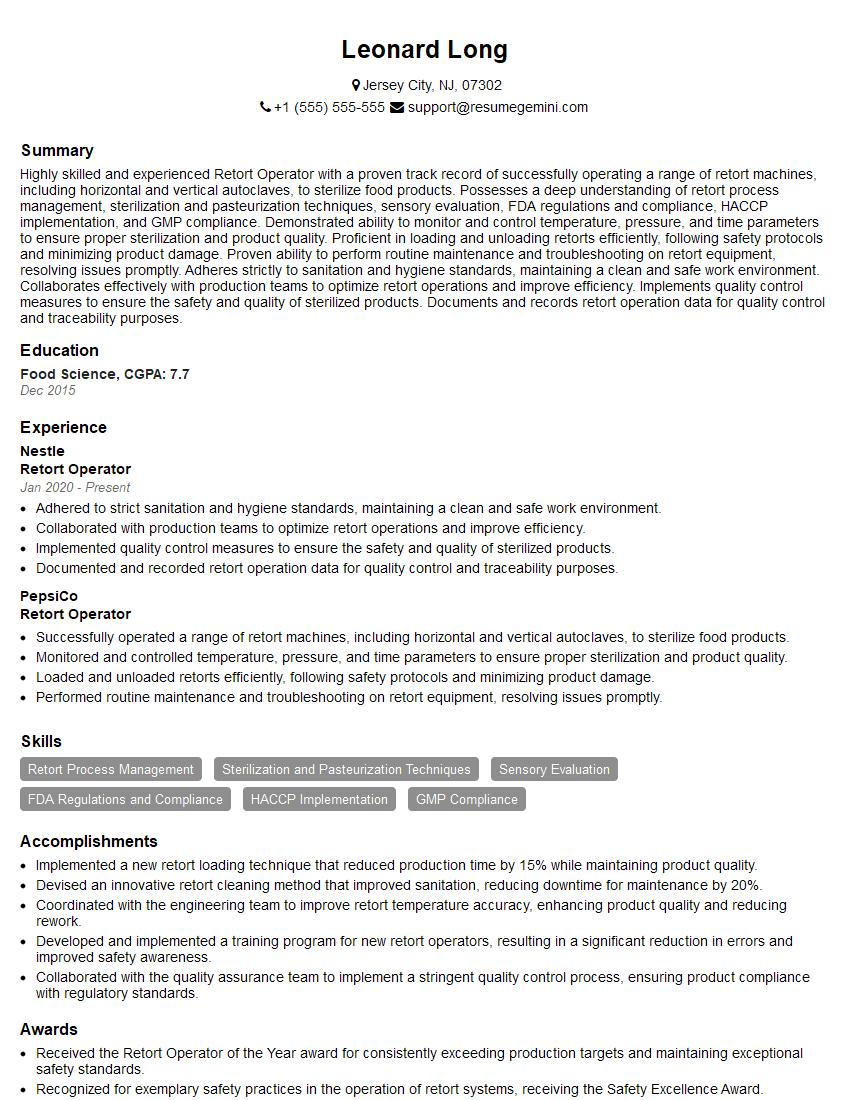

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Retort Operator

1. Describe the key responsibilities of a Retort Operator.

The key responsibilities of a Retort Operator include:

- Operating and monitoring retort systems to sterilize food products.

- Ensuring that products meet quality and safety standards.

- Maintaining a safe and clean work environment.

2. What are the different types of retorts used in the food industry?

Steam Retorts

- Use saturated steam to sterilize products.

- Commonly used for low-acid foods.

Hydrostatic Retorts

- Use hot water or a water-steam mixture to sterilize products.

- Suitable for high-acid foods.

Rotary Retorts

- Use a rotating drum to move products through the sterilization process.

- Can sterilize both large and small containers.

3. Explain the process of conducting a temperature profile in a retort.

A temperature profile involves monitoring the temperature of a product during the sterilization process to ensure it reaches the target temperature and holds it for the required time.

- Place a temperature probe in the product.

- Start the sterilization cycle.

- Record the temperature readings at regular intervals.

- Analyze the data to ensure compliance with sterilization requirements.

4. What are the critical control points (CCPs) in retort operations?

Critical control points in retort operations include:

- Temperature control during sterilization.

- Time control during sterilization.

- Cooling rate after sterilization.

- Container integrity.

- Process validation.

5. How do you ensure the safety of food products after retorting?

To ensure the safety of food products after retorting, it is important to:

- Follow established sterilization protocols.

- Monitor critical control points during the sterilization process.

- Conduct product testing to verify sterility.

- Implement proper handling and storage procedures.

6. Describe the maintenance procedures for retort systems.

Maintenance procedures for retort systems include:

- Inspecting and cleaning retorts regularly.

- Lubricating moving parts.

- Calibrating temperature and pressure gauges.

- Testing safety systems.

7. What is the role of a Retort Operator in food safety management?

Retort Operators play a vital role in food safety management by:

- Adhering to established sterilization protocols.

- Monitoring critical control points during processing.

- Reporting any deviations from standard procedures.

- Participating in food safety training and audits.

8. How do you handle situations where a retort system malfunction occurs?

In the event of a retort system malfunction, it is important to:

- Stop the sterilization process immediately.

- Identify the source of the malfunction.

- Follow established emergency procedures.

- Document the incident and notify the supervisor.

9. What are the industry standards and regulations that govern retort operations?

Retort operations must comply with various industry standards and regulations, including:

- FDA’s Current Good Manufacturing Practices (CGMPs)

- USDA’s Food Safety and Inspection Service (FSIS) regulations

- American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code

10. How do you stay updated on the latest advancements in retort technology and best practices?

To stay updated on advancements and best practices in retort technology, it is important to:

- Attend industry conferences and workshops.

- Read technical publications and journals.

- Network with other retort operators and experts.

- Receive training from equipment manufacturers and industry organizations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Retort Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Retort Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Retort Operator is responsible for operating and maintaining retort equipment used in the sterilization of food products. They ensure that the products meet safety and quality standards. Key job responsibilities include:

1. Operation of Retort Equipment

Operate retort equipment to sterilize food products according to established procedures.

- Monitor and adjust retort operating parameters, including temperature, pressure, and time.

- Ensure that all equipment is functioning properly and safely.

2. Product Quality Control

Conduct quality control checks on sterilized products to ensure they meet safety and quality standards.

- Inspect products for any defects or contamination.

- Take corrective actions if any deviations from standards are observed.

3. Maintenance and Troubleshooting

Perform routine maintenance and troubleshooting on retort equipment to ensure optimal performance.

- Identify and resolve any mechanical or electrical issues.

- Keep accurate records of maintenance and repairs.

4. Compliance with Regulations

Ensure compliance with all applicable food safety and quality regulations.

- Follow established protocols for sterilization and product handling.

- Maintain a clean and sanitary work environment.

5. Teamwork and Communication

Work effectively as part of a team and communicate clearly with supervisors, colleagues, and customers.

- Provide support to other operators and assist with training.

- Participate in safety meetings and training programs.

Interview Tips

To ace your interview for a Retort Operator position, follow these tips:

1. Research the Company and Industry

Demonstrate your interest in the company and the food industry by researching their products, values, and recent developments.

- Visit the company’s website and read industry news and publications.

- Be prepared to discuss your understanding of the retort sterilization process.

2. Highlight Relevant Skills and Experience

Emphasize your skills in operating and maintaining retort equipment. Quantify your experience with specific examples.

- Provide details of your involvement in product quality control and compliance initiatives.

- Describe your role in troubleshooting and resolving equipment issues.

3. Demonstrate Attention to Detail

Retort Operators must be meticulous in their work. Highlight your attention to detail and ability to follow procedures precisely.

- Share experiences where you identified and corrected product defects.

- Explain how you maintain and calibrate equipment to ensure accuracy.

4. Emphasize Safety and Compliance

Convey your commitment to safety and compliance in the food industry.

- Describe your understanding of food safety regulations and sterilization standards.

- Explain how you ensure a clean and sanitary work environment.

5. Show Enthusiasm and a Positive Attitude

Retort Operators play a crucial role in food safety. Express your passion for the industry and your dedication to ensuring product quality.

- Share your interest in food processing and your desire to contribute to the safety of the food supply.

- Maintain a positive and enthusiastic attitude throughout the interview.

Next Step:

Now that you’re armed with the knowledge of Retort Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Retort Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini