Are you gearing up for an interview for a Yeast Distiller position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Yeast Distiller and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

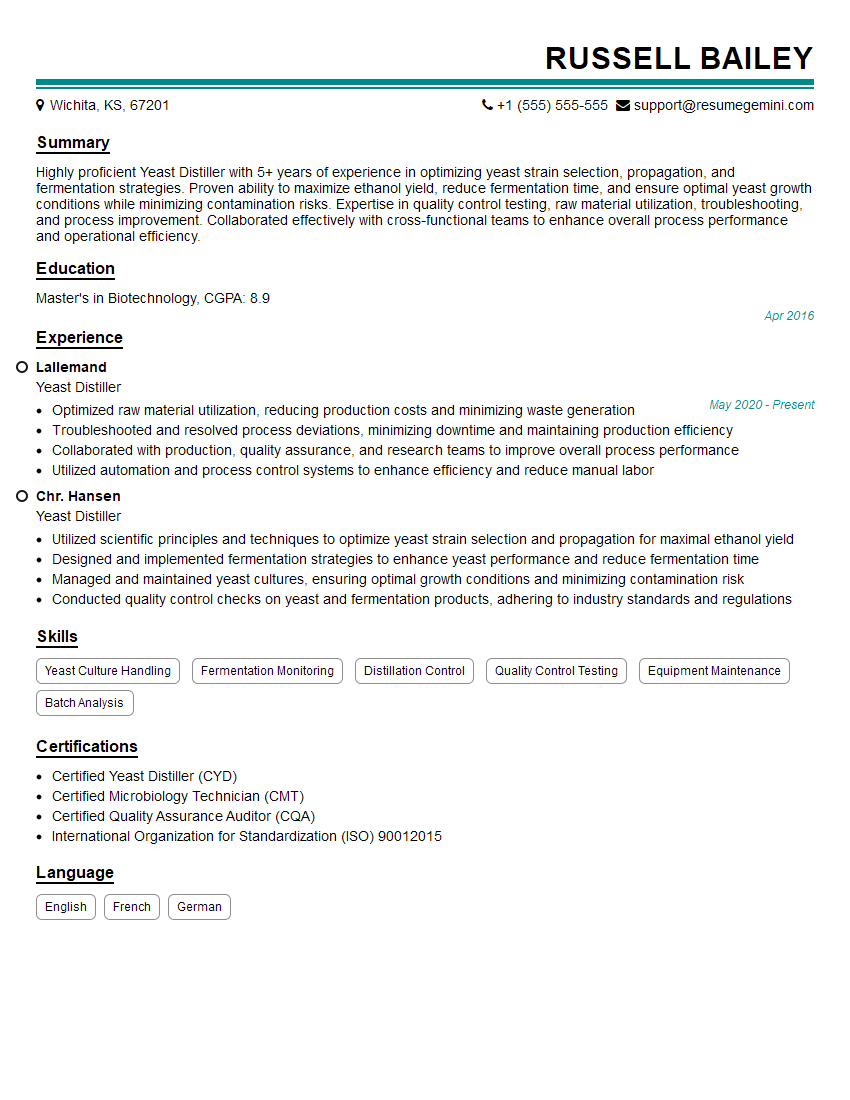

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Yeast Distiller

1. What are the different types of yeast used in distillation and how do they impact the final product?

- Saccharomyces cerevisiae: This is the most commonly used yeast in distillation. It is responsible for producing ethanol and carbon dioxide from sugars. Different strains of S. cerevisiae can produce different flavors and aromas in the final product.

- Saccharomyces uvarum: This yeast is used in the production of wine. It produces lower levels of ethanol than S. cerevisiae and can impart a more fruity flavor to the final product.

- Brettanomyces: This yeast is used in the production of some Belgian beers and lambics. It can produce a variety of flavors and aromas, including fruity, spicy, and earthy notes.

- Wild Yeast: These yeasts are found naturally on fruits and grains. They can produce a variety of flavors and aromas in the final product, depending on the specific strain of yeast.

2. What are the key factors that affect yeast fermentation during distillation?

Temperature

- Yeast fermentation is an exothermic process, meaning that it produces heat. The ideal temperature for yeast fermentation is between 25-30°C (77-86°F).

- Temperatures below 20°C (68°F) can slow down fermentation and lead to the production of off-flavors.

- Temperatures above 35°C (95°F) can kill the yeast and stop fermentation.

pH

- The pH of the fermentation medium can also affect yeast fermentation. The ideal pH for yeast fermentation is between 4.5-5.5.

- A pH below 4.0 can inhibit yeast growth and fermentation.

- A pH above 6.0 can lead to the production of off-flavors.

3. What are the different methods of yeast propagation and how do they affect the fermentation process?

- Batch propagation: This is the simplest method of yeast propagation. Yeast is added to a sterile medium and allowed to grow for a period of time. Once the yeast has reached the desired cell density, it is harvested and used for fermentation.

- Continuous propagation: This method involves adding fresh medium to a yeast culture on a regular basis. This allows the yeast to grow continuously and maintain a high cell density. Continuous propagation can be used to produce large volumes of yeast for fermentation.

- Fed-batch propagation: This method is a combination of batch and continuous propagation. Fresh medium is added to the yeast culture at regular intervals, but the rate of addition is controlled to maintain a specific cell density. Fed-batch propagation can be used to produce large volumes of yeast with a high cell density.

4. What are the common problems that can occur during yeast fermentation and how can they be prevented or corrected?

-

Slow or incomplete fermentation: This can be caused by a number of factors, including low yeast cell density, incorrect temperature or pH, or the presence of inhibitors. To prevent slow or incomplete fermentation, it is important to ensure that the yeast is healthy and active, the fermentation medium is at the correct temperature and pH, and there are no inhibitors present.

- Off-flavors: Off-flavors can be caused by a number of factors, including the presence of contaminants, incorrect fermentation temperature or pH, or the use of the wrong type of yeast. To prevent off-flavors, it is important to use clean equipment and ingredients, maintain the correct fermentation temperature and pH, and use the right type of yeast for the desired flavor profile.

- Yeast infections: Yeast infections can occur if the yeast is contaminated with bacteria or other microorganisms. To prevent yeast infections, it is important to use clean equipment and ingredients, and to maintain the correct fermentation temperature and pH.

5. What are the different types of distillation equipment used in yeast distillation and how do they affect the final product?

- Pot stills: Pot stills are the oldest and simplest type of distillation equipment. They consist of a pot or kettle that is heated to vaporize the alcohol. The vapors are then condensed and collected. Pot stills produce a full-flavored distillate with a high congeners content.

- Column stills: Column stills are more efficient than pot stills and can produce a higher-purity distillate. They consist of a column that is filled with packing material. The alcohol vapors rise through the packing material and are condensed and collected. Column stills produce a lighter-flavored distillate with a lower congeners content.

- Hybrid stills: Hybrid stills combine features of both pot stills and column stills. They can produce a variety of distillates with different flavor profiles.

6. What are the different factors that affect the yield and quality of the final distillate?

-

The type of yeast used: Different types of yeast produce different flavors and aromas in the final distillate.

- The fermentation conditions: The temperature, pH, and other factors during fermentation can affect the yield and quality of the distillate.

- The distillation equipment used: The type of distillation equipment used can also affect the yield and quality of the distillate.

- The skill of the distiller: The skill of the distiller can also play a role in the yield and quality of the distillate.

7. What are the different quality control tests that can be performed on yeast and distilled spirits?

- Yeast viability: This test measures the percentage of yeast cells that are alive and active.

- Yeast purity: This test checks for the presence of contaminants in the yeast culture.

- Alcohol content: This test measures the percentage of alcohol in the distilled spirits.

- Congeners content: This test measures the presence of other compounds in the distilled spirits, such as esters, aldehydes, and ketones.

- Sensory evaluation: This test evaluates the flavor and aroma of the distilled spirits.

8. What are the different regulations that govern the production and sale of distilled spirits?

- The Alcohol and Tobacco Tax and Trade Bureau (TTB): The TTB is the federal agency responsible for regulating the production and sale of distilled spirits in the United States.

- The Food and Drug Administration (FDA): The FDA is the federal agency responsible for regulating the safety of food and beverages, including distilled spirits.

- State and local governments: State and local governments also have regulations governing the production and sale of distilled spirits.

9. What are the different career paths available to yeast distillers?

- Production manager: Production managers are responsible for overseeing the production of distilled spirits.

- Quality control manager: Quality control managers are responsible for ensuring that distilled spirits meet quality standards.

- Sales manager: Sales managers are responsible for selling distilled spirits to distributors and retailers.

- Marketing manager: Marketing managers are responsible for developing and implementing marketing campaigns for distilled spirits.

- Distillery owner: Distillery owners are responsible for owning and operating a distillery.

10. What are your strengths and weaknesses as a yeast distiller?

Strengths:- I have a strong understanding of the yeast fermentation process.

- I am experienced in operating different types of distillation equipment.

- I am passionate about producing high-quality distilled spirits.

- I am relatively new to the industry.

- I do not have a formal education in distilling.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Yeast Distiller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Yeast Distiller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Yeast Distillers are responsible for cultivating and maintaining yeast cultures for the production of alcoholic beverages, pharmaceuticals, and other industrial applications. Key job responsibilities include:

1. Yeast Management

Cultivating, propagating, and maintaining yeast strains to ensure optimal growth and performance.

- Monitoring yeast growth and viability

- Performing quality control tests to ensure yeast purity and viability

2. Fermentation Process

Designing and optimizing fermentation processes to maximize yeast efficiency and product yield.

- Selecting and preparing fermentation media

- Monitoring and controlling fermentation parameters (e.g., temperature, pH, aeration)

3. Equipment Maintenance

Ensuring the proper operation and maintenance of yeast fermentation and distillation equipment.

- Cleaning and sterilizing equipment

- Performing routine maintenance and calibrations

4. Quality Control and Safety

Conducting quality control tests on yeast products and ensuring adherence to safety and regulatory guidelines.

- Testing yeast purity, viability, and product quality

- Implementing safety protocols and maintaining a clean and sterile work environment

5. Research and Development

Participating in research and development projects to improve yeast strains and fermentation processes.

- Evaluating new yeast strains and technologies

- Developing innovative fermentation techniques

Interview Tips

To ace the interview for a Yeast Distiller position, candidates should consider the following tips:

1. Research and Preparation

Thoroughly research the company, the job description, and the industry to demonstrate your understanding and interest.

- Study key concepts related to yeast distillation, fermentation, and quality control.

- Prepare questions to ask the interviewer to show your engagement and curiosity.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills, such as yeast culture management, fermentation optimization, and quality control techniques.

- Provide specific examples of projects or responsibilities that showcase your abilities.

- Quantify your achievements using metrics to demonstrate the impact of your work.

3. Showcase Your Passion for Yeast Distillation

Express your enthusiasm for the field and your commitment to producing high-quality yeast products.

- Discuss your interests in the industry and any personal projects related to yeast distillation.

- Share your vision for how you can contribute to the company’s success in this area.

4. Be Prepared for Technical Questions

Anticipate technical questions about yeast cultivation, fermentation processes, and distillation techniques.

- Review your knowledge and prepare concise answers that demonstrate your understanding.

- Consider using examples from your previous experience to illustrate your responses.

5. Ask Thoughtful Questions

Prepare intelligent questions to ask the interviewer, which not only demonstrate your engagement but also provide you with valuable insights.

- Ask about the company’s fermentation processes, product quality standards, or future plans.

- Inquire about opportunities for professional development and growth within the organization.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Yeast Distiller, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Yeast Distiller positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.