Feeling lost in a sea of interview questions? Landed that dream interview for CNC Operator (Computer Numeric Control Operator) but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common CNC Operator (Computer Numeric Control Operator) interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

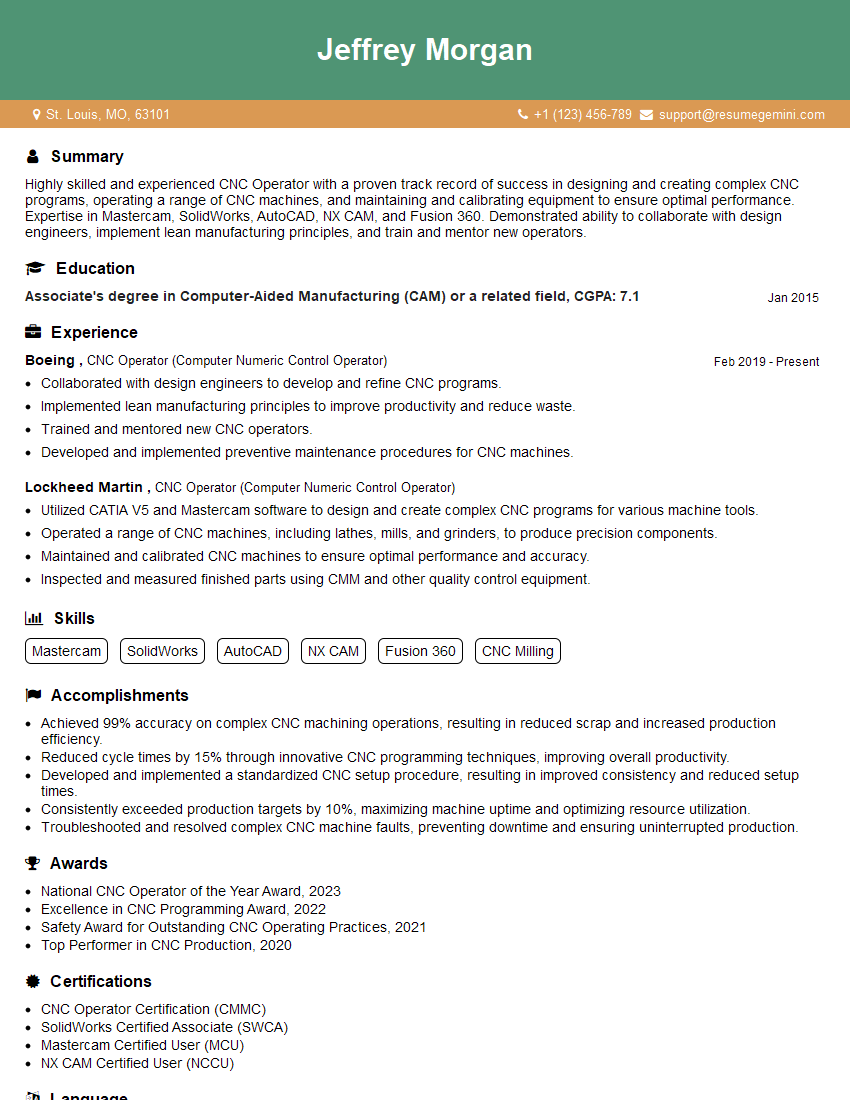

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For CNC Operator (Computer Numeric Control Operator)

1. What are the different types of CNC machines and their applications?

There are several types of CNC machines, each designed for specific applications. Some common types include:

- CNC Mills: Used for cutting and shaping metal, plastic, and other materials using rotating cutting tools.

- CNC Lathes: Used for turning and shaping cylindrical workpieces, such as shafts and gears.

- CNC Routers: Used for cutting and carving wood, plastics, and composite materials.

- CNC Grinders: Used for grinding and finishing metal surfaces to achieve precise dimensions and surface finishes.

- CNC EDM (Electrical Discharge Machining): Used for cutting complex shapes and features in hard and difficult-to-machine materials using electrical discharges.

2. Explain the process of developing and running a CNC program.

Creating the CNC Program

- Design: Create a 3D model or drawing of the part to be machined.

- CAM (Computer-Aided Machining): Use CAM software to generate the CNC program based on the design.

Running the CNC Program

- Setup: Mount the workpiece on the CNC machine, set up the cutting tools, and calibrate the machine.

- Loading Program: Load the CNC program into the machine’s control system.

- Execution: Start the CNC program and monitor its progress, making adjustments as needed.

3. What are the different cutting tools used in CNC machining and their applications?

- End Mills: Used for cutting pockets, slots, and contours.

- Drills: Used for creating holes.

- Taps: Used for creating threads.

- Boring Bars: Used for enlarging existing holes and creating precision bores.

- Reamers: Used for finishing holes to achieve precise dimensions and surface finishes.

4. Describe the different types of workholding devices used in CNC machining and their advantages/disadvantages.

Types of Workholding Devices:

- Vises: Hold workpieces securely using jaws that can be tightened or loosened.

- Clamps: Clamp workpieces to the CNC table or fixture.

- Fixtures: Custom-designed devices that hold workpieces in a specific orientation and position.

- Chucks: Used on lathes to hold cylindrical workpieces.

Advantages/Disadvantages:

Consider factors such as workpiece shape, size, and accuracy requirements when selecting the appropriate workholding device.5. How do you set up and calibrate a CNC machine?

Setting up and calibrating a CNC machine involves:

- Mechanical Setup: Mount the workpiece, install the cutting tools, and ensure proper alignment.

- Tool Offset Calibration: Determine and set the positions of the cutting tools relative to the workpiece.

- Machine Calibration: Use precision instruments to verify the accuracy of the machine’s movements and axes.

6. What are some common troubleshooting techniques for CNC machines?

- Check for Errors: Review the CNC program for any errors or inconsistencies.

- Inspect Tooling: Ensure that the cutting tools are sharp, undamaged, and properly installed.

- Examine Workpiece: Check the workpiece for any defects or inconsistencies that may affect machining.

- Calibrate Machine: Recalibrate the machine’s axes and tool offsets to ensure accuracy.

7. Describe the importance of coolant in CNC machining and its different types.

Coolant plays a crucial role in CNC machining by:

- Temperature Control: Dissipating heat generated during cutting, preventing tool and workpiece damage.

- Chip Removal: Flushing away chips and debris from the cutting zone, improving surface finish and extending tool life.

- Lubrication: Reducing friction between the tool and workpiece, minimizing wear and extending tool life.

Types of Coolant:

- Flooding Coolant: Sprayed or poured directly onto the cutting zone.

- Mist Coolant: Atomized spray of coolant that reduces coolant consumption and environmental impact.

- Cryogenic Coolant: Sub-zero temperature coolant that provides better cooling and lubrication.

8. What are the safety precautions to consider when operating a CNC machine?

- Wear Proper Safety Gear: Including safety glasses, gloves, and hearing protection.

- Secure Workpiece: Ensure the workpiece is securely clamped or held in place.

- Clear Work Area: Keep the CNC machine area free of debris and tripping hazards.

- Follow Operating Procedures: Adhere to established safety guidelines and protocols.

- Never Reach into a Running Machine: Avoid touching the machine or workpiece while it is operating.

9. Explain the concept of G-codes and M-codes in CNC programming.

G-Codes:

- Geometric Codes: Control machine movements, such as X, Y, and Z axes positioning.

- Motion Codes: Define motion types, such as linear, circular, and rapid.

M-Codes:

- Miscellaneous Codes: Control non-motion functions, such as tool changes, spindle speeds, and coolant on/off.

10. What are the key maintenance tasks for a CNC machine?

- Regular Cleaning: Remove chips, debris, and coolant from the machine.

- Spindle Lubrication: Lubricate the spindle bearings regularly to prevent wear and ensure smooth operation.

- Axis Maintenance: Clean and lubricate the machine’s axes to maintain accuracy and precision.

- Tool Inspection: Check cutting tools for wear and damage, replacing them as needed.

- Electrical Inspection: Inspect electrical components for any signs of damage or loose connections.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for CNC Operator (Computer Numeric Control Operator).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the CNC Operator (Computer Numeric Control Operator)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities for a CNC Operator

CNC Operators are responsible for programming and operating computer numerically controlled (CNC) machines to manufacture precise parts. Their key responsibilities include:1. Programming CNC Machines

CNC Operators use computer-aided design (CAD) software to create or modify CNC programs. These programs provide the machine with instructions on how to move, cut, or shape the workpiece.

- Plan and design tooling, fixtures and machine processes

- Develop and optimize CNC programs

2. Operating CNC Machines

Once the program is created, the CNC Operator mounts the workpiece onto the CNC machine and initiates the program. They monitor the machine’s progress and make adjustments as needed.

- Set up CNC machines according to specifications

- Load materials, check tolerances, and monitor machine operations

- Make adjustments to the machine or program to ensure optimal performance and workpiece accuracy

3. Quality Control

CNC Operators are responsible for ensuring that the parts produced by the machine meet the required quality standards. They visually inspect the parts and use measuring instruments to verify accuracy.

- Inspect the final products for errors and accuracy

- Measure and verify that the parts conform to specifications

- Maintain detailed records of all inspections and measurements

4. Machine Maintenance

CNC Operators are also responsible for maintaining the CNC machines. They perform daily inspections, lubricate moving parts, and make minor repairs.

- Lubricate, adjust, and maintain CNC machines

- Troubleshoot and resolve machine issues

- Adhere to safety protocols and regulations

Interview Tips for a CNC Operator

To ace a CNC Operator interview, it is crucial to have a strong understanding of the job responsibilities and the industry. Here are some interview preparation tips and hacks:1. Research the Company and the Position

Read the company’s website and the job description carefully. This will give you a good understanding of their business, the role you are applying for, and the skills and experience they are seeking.

2. Prepare Your Resume and Portfolio

Highlight your relevant skills and experience on your resume. If you have any examples of your work, such as previous CNC programs or projects, be sure to bring them to the interview.

3. Practice Common Interview Questions

There are several common interview questions that you are likely to encounter. Prepare your answers to these questions in advance so that you can deliver them confidently.

4. Be Enthusiastic and Professional

Employers are looking for candidates who are passionate about their work and who are eager to learn and grow. Show your enthusiasm for the CNC industry and demonstrate your commitment to delivering high-quality work.

5. Ask Questions

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. Prepare a few questions that will help you gain a better understanding of the company and the role.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the CNC Operator (Computer Numeric Control Operator) role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.