Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Numerical Control Jig Boring Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Numerical Control Jig Boring Machine Operator so you can tailor your answers to impress potential employers.

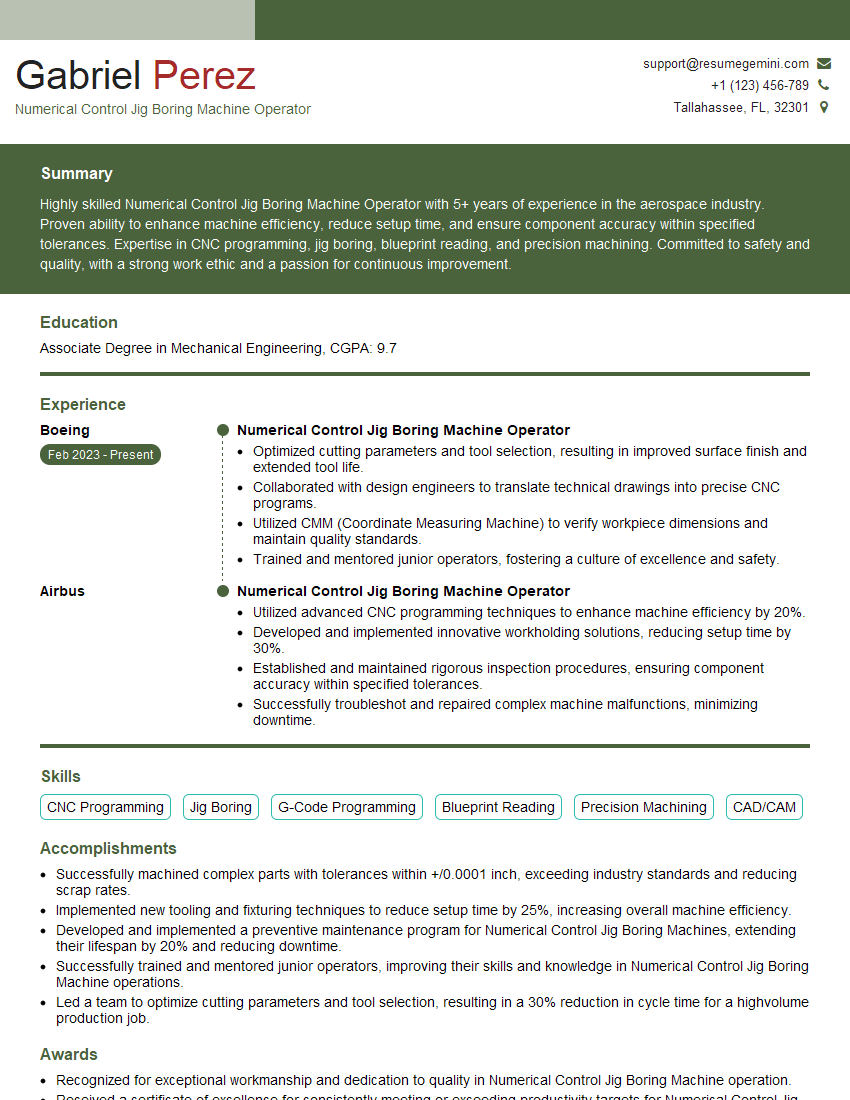

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Numerical Control Jig Boring Machine Operator

1. Describe the key responsibilities of a Numerical Control Jig Boring Machine Operator?

- Setting up and operating Numerical Control (NC) jig boring machines to produce precision parts

- Reading and interpreting blueprints and engineering drawings

- Performing quality control checks on finished parts

- Maintaining and calibrating NC jig boring machines

- Troubleshooting and resolving problems with NC jig boring machines

2. What are the different types of Numerical Control Jig Boring Machines?

types of NC jig boring machines

- Horizontal spindle machines

- Vertical spindle machines

- Bridge-type machines

- CNC jig boring machines

features of NC jig boring machines

- High precision and accuracy

- Automatic tool changing

- Computer-aided design (CAD) and computer-aided manufacturing (CAM) capabilities

3. What are the key skills and qualifications required for a Numerical Control Jig Boring Machine Operator?

- Strong understanding of the principles of NC jig boring

- Experience in operating NC jig boring machines

- Proficient in reading and interpreting blueprints and engineering drawings

- Skilled in performing quality control checks

- Ability to troubleshoot and resolve problems with NC jig boring machines

4. How do you ensure the accuracy and precision of parts produced on a Numerical Control Jig Boring Machine?

- Using high-precision tools and fixtures

- Calibrating the machine regularly

- Following the specified operating procedures

- Performing quality control checks on finished parts

5. What are the safety precautions that must be taken when operating a Numerical Control Jig Boring Machine?

- Wearing appropriate safety gear, such as safety glasses, gloves, and earplugs

- Keeping the work area clean and free of debris

- Following the specified operating procedures

- Being aware of the potential hazards associated with the machine

6. How do you troubleshoot common problems that may occur with a Numerical Control Jig Boring Machine?

- Identifying the source of the problem

- Consulting the machine’s manual or troubleshooting guide

- Performing the necessary repairs or adjustments

- Testing the machine to ensure that the problem has been resolved

7. What are the latest trends in Numerical Control Jig Boring Machine technology?

- Increased use of CNC technology

- Development of more user-friendly software

- Integration of advanced sensors and monitoring systems

8. How do you stay up-to-date on the latest developments in Numerical Control Jig Boring Machine technology?

- Reading industry publications

- Attending trade shows and conferences

- Participating in online forums and discussion groups

9. What are your career goals as a Numerical Control Jig Boring Machine Operator?

- To become a highly skilled and experienced NC jig boring machine operator

- To learn about the latest advancements in NC jig boring machine technology

- To contribute to the success of my company

10. Why should we hire you as a Numerical Control Jig Boring Machine Operator?

- I have the necessary skills and experience to be an effective NC jig boring machine operator

- I am committed to producing high-quality work

- I am a team player and I am always willing to learn new things

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Numerical Control Jig Boring Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Numerical Control Jig Boring Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Numerical Control Jig Boring Machine Operators are responsible for the precise and efficient operation of Numerical Control (NC) jig boring machines to create precision parts and assemblies. Their primary tasks include:

1. Machine Setup and Programming

• Configuring and setting up the NC jig boring machine according to specifications

• Loading and securing workpieces and fixtures

• Programming the machine using Computer-aided Manufacturing (CAM) software or manual code

2. Machine Operation

• Activating and monitoring the machine during operation

• Ensuring proper tool selection and cutting parameters

• Troubleshooting and resolving any machine or tooling issues

3. Quality Control and Inspection

• Conducting in-process and final inspections of machined parts

• Using measuring tools and equipment to verify dimensions and tolerances

• Maintaining a record of inspection results and identifying any non-conformances

4. Maintenance and Troubleshooting

• Performing basic maintenance tasks on the machine, such as lubrication and cleaning

• Identifying and diagnosing machine malfunctions

• Reporting any maintenance or repair requirements

Interview Tips

To ace the interview for a Numerical Control Jig Boring Machine Operator position, candidates should:

1. Research the Company and Industry

• Learn about the company’s products, services, and industry

• Identify any specific requirements or expectations for the role

2. Showcase Technical Skills and Experience

• Emphasize proficiency in operating and programming NC jig boring machines

• Highlight experience in precision machining, quality control, and troubleshooting

3. Prepare Examples and Quantify Results

• Provide specific examples of successful projects or challenges faced in previous roles

• Quantify accomplishments whenever possible, using metrics and data

4. Demonstrate Attention to Detail and Precision

• Highlight a strong understanding of dimensional tolerances and quality standards

• Convey attention to detail and a commitment to producing accurate and precise work

5. Ask Insightful Questions

• Prepare thoughtful questions about the company, the role, and the industry

• Questions demonstrate engagement and interest in the position

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Numerical Control Jig Boring Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!