Are you gearing up for an interview for a Numerical Control Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Numerical Control Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

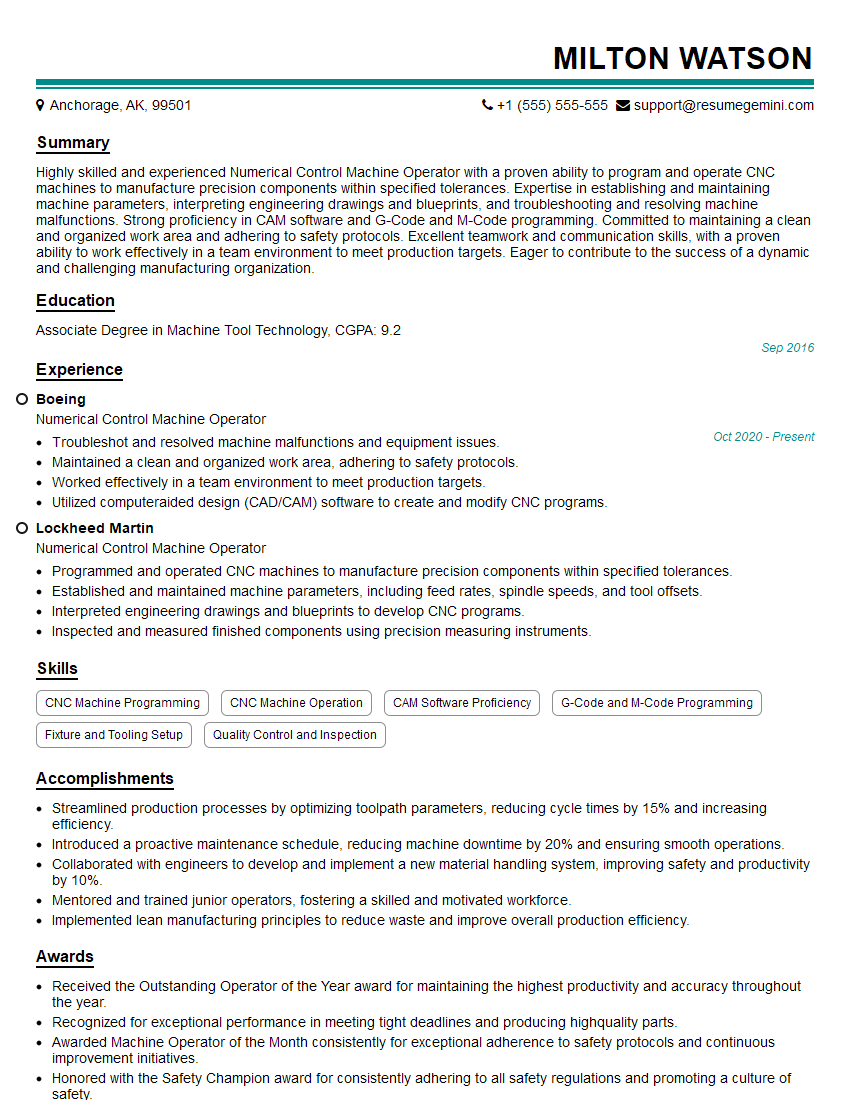

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Numerical Control Machine Operator

1. Describe the process of setting up a new workpiece on a Numerical Control (NC) machine?

Sample Answer:

- Securely mount the workpiece to the machine table using appropriate fixtures.

- Zero the machine axes relative to the workpiece reference point.

- Load the NC program into the machine control system.

- Set tool offsets and length compensation values.

- Perform a dry run or simulation to verify the program and toolpath.

2. Explain how to troubleshoot common errors that occur during NC machining, such as tool breakage, part inaccuracies, and surface finish problems?

Sample Answer:

- Tool breakage: Check tool condition, verify tool offset values, inspect for excessive cutting forces.

- Part inaccuracies: Examine NC program for errors, check machine accuracy and alignment, inspect for tool wear or damage.

- Surface finish problems: Adjust cutting parameters, check for proper tool selection, ensure optimal workpiece material conditions, consider lubrication or coolant use.

3. What types of NC programming software are you familiar with? Describe their capabilities and limitations?

Sample Answer:

- CAM software: Allows for 3D modeling, toolpath generation, and post-processing (e.g., Mastercam, SolidWorks).

- G-code editors: Enables manual creation and editing of NC programs (e.g., Notepad++, Visual Studio Code).

- Interpreter-based systems: Provide flexibility in program modification at the machine interface (e.g., Heidenhain, Fanuc).

4. How do you ensure the accuracy and precision of NC machined parts?

Sample Answer:

- Regularly calibrate and maintain the machine tool, including axis alignment and position feedback systems.

- Use high-quality cutting tools and materials with appropriate tolerances.

- Implement quality control procedures, such as dimensional inspection and surface roughness measurements.

- Monitor and adjust cutting parameters (e.g., feed rates, spindle speeds) to optimize performance.

5. Discuss the safety precautions that must be taken when operating an NC machine?

Sample Answer:

- Always wear appropriate safety gear (e.g., goggles, gloves, earplugs).

- Ensure proper guarding and interlocks are in place.

- Inspect the machine and tooling before each use.

- Be aware of the potential for flying chips and coolant.

- Follow established safety procedures and protocols.

6. What maintenance tasks are required to keep an NC machine running in optimal condition?

Sample Answer:

- Regular lubrication and cleaning of mechanical components.

- Inspection and replacement of worn or damaged parts.

- Software updates and firmware maintenance.

- Preventive maintenance schedules to address potential issues.

- Monitoring of machine performance and diagnostic reporting.

7. How do you handle complex machining operations involving multiple axes and complex geometries?

Sample Answer:

- Utilize advanced programming techniques (e.g., subroutines, macros).

- Leverage CAM software for collision avoidance and toolpath optimization.

- Conduct thorough simulations and dry runs to verify program integrity.

- Employ appropriate fixturing and workholding methods to ensure part stability.

8. Describe your experience in working with different types of materials, such as metals, plastics, and composites?

Sample Answer:

- Metals: Steel, aluminum, titanium, exotic alloys (e.g., Inconel).

- Plastics: Acrylic, polycarbonate, polyethylene, composites (e.g., carbon fiber).

- Composites: Fiberglass, Kevlar, honeycomb structures.

- Knowledge of specific cutting parameters, tool selection, and fixturing techniques for each material.

9. What are your strengths and weaknesses as an NC machine operator?

Sample Answer:

-

Strengths:

- Proficient in G-code programming and CAM software.

- Excellent attention to detail and quality assurance.

- Strong understanding of machine operation and maintenance. Weaknesses:

- Limited experience with certain advanced machining techniques.

- Working in a fast-paced environment with tight deadlines.

10. Why are you interested in this position, and how do you think your skills and experience would benefit our company?

Sample Answer:

- Enthusiasm for challenging and demanding roles in the manufacturing industry.

- Desire to contribute to a team-oriented environment focused on precision and efficiency.

- Belief that my skills in NC programming, machine operation, and quality control would add value to your production process.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Numerical Control Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Numerical Control Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Numerical Control Machine Operators are responsible for operating and maintaining numerically controlled (NC) machines, which are used in the manufacturing industry to produce complex parts with high precision. Their primary responsibilities include:

1. Machine Setup and Operation

Setting up and operating NC machines according to blueprints and specifications.

- Loading and unloading raw materials.

- Entering and modifying NC programs.

- Monitoring machine performance and making adjustments as needed.

2. Inspection and Quality Control

Inspecting finished parts to ensure they meet quality standards.

- Using measuring tools and gauges.

- Identifying and correcting defects.

- Maintaining records of inspections.

3. Maintenance and Troubleshooting

Conducting routine maintenance on NC machines to ensure optimal performance.

- Lubricating and cleaning machines.

- Identifying and troubleshooting mechanical and electrical problems.

- Performing minor repairs.

4. Safety and Compliance

Following all safety protocols and regulations.

- Wearing appropriate personal protective equipment.

- Maintaining a clean and organized work area.

- Adhering to environmental regulations.

Interview Tips

Preparing for a Numerical Control Machine Operator interview requires thorough understanding of the role, its responsibilities, and the industry. Here are some preparation tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and industry. Research their website, news articles, and LinkedIn page. This knowledge will help you understand their business objectives and align your skills with their needs.

2. Highlight Your Machine Operation Skills

Emphasize your experience operating different types of NC machines. Quantify your accomplishments by providing specific examples of complex parts you have produced, the tolerances you achieved, and any productivity improvements you implemented.

3. Demonstrate Troubleshooting Abilities

Interviewers want to know that you can resolve issues independently. Share examples of how you identified and solved machine problems, reduced downtime, and ensured smooth production flow.

4. Explain Safety and Quality Control Practices

Highlight your commitment to safety and quality. Describe the safety protocols you follow, explain how you inspect finished parts, and mention any quality improvement initiatives you have participated in.

5. Showcase Your Industry Knowledge

Stay up-to-date with the latest advancements in NC technology and industry trends. Discussing these topics shows that you are passionate about your field and eager to embrace new developments.

6. Prepare for Technical Questions

Practice answering questions about NC programming, machine setup, and troubleshooting. Be prepared to discuss different types of cutting tools, workholding devices, and measurement techniques.

7. Emphasize Your Attention to Detail

Numerical Control Machine Operators must be meticulous and detail-oriented. Provide examples of how you ensure accuracy in your work, such as using measuring tools precisely and following blueprints carefully.

8. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows your interest in the company and the position. Consider asking about their growth plans, training opportunities, or the latest projects they are working on.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Numerical Control Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Numerical Control Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.