Feeling lost in a sea of interview questions? Landed that dream interview for Robotic Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Robotic Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

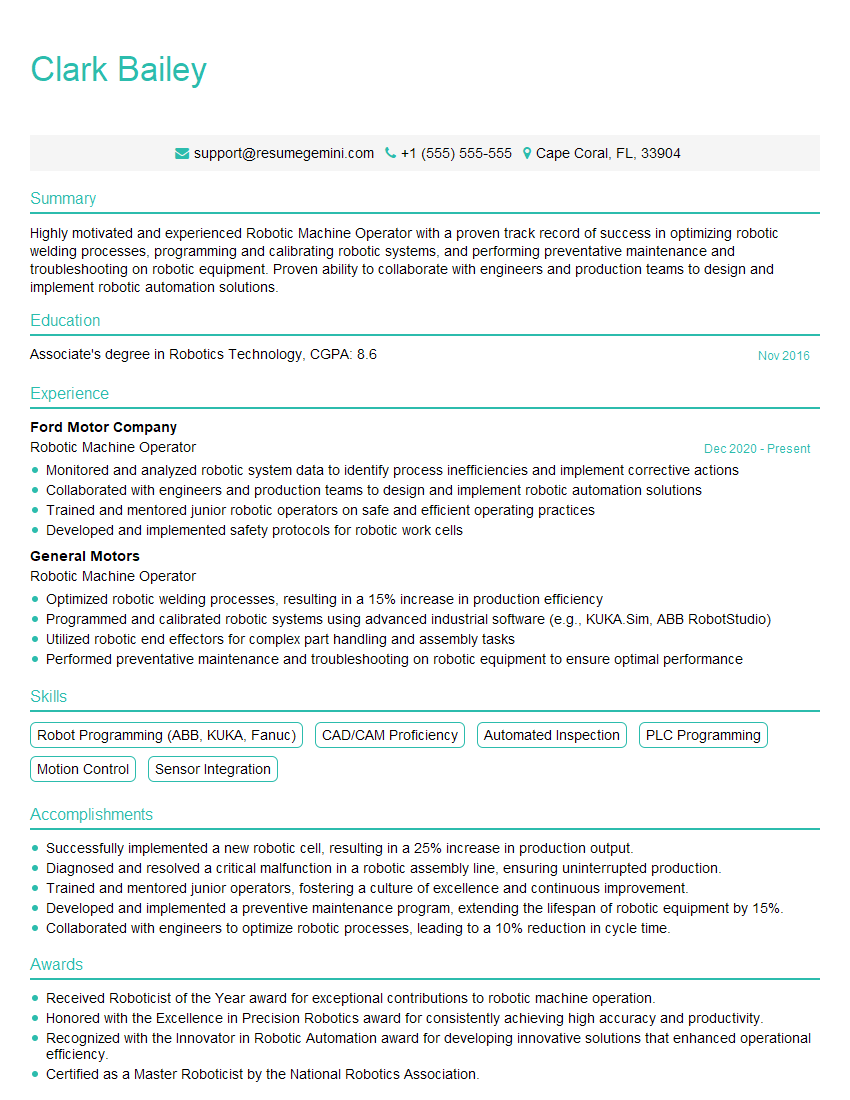

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Robotic Machine Operator

1. Explain how motion control is used in robotics?

Motion control is essential in robotics as it allows the precise and coordinated movement of robotic arms. Here are some specific applications of motion control in robotics:

- Controlling the movement of robotic arms for precise tasks such as manufacturing, assembly, and painting.

- Ensuring smooth and accurate movement of robots in automated systems, such as assembly lines and packaging machines.

- Enabling robots to navigate and interact with their environment, including obstacle avoidance and path planning.

- Providing feedback and error correction to ensure accurate and repeatable movements.

2. What are the different types of actuators used in robotics?

There are several types of actuators used in robotics, each with its own advantages and applications:

Electric Actuators

- Servomotors: High precision and torque, used in applications requiring precise motion control.

- Steppers: Low cost and simple to control, used in applications with limited precision requirements.

- DC Motors: Versatile and inexpensive, used in a wide range of robotics applications.

Pneumatic Actuators

- Air Cylinders: Provide high force and speed, used in applications requiring heavy lifting or fast actuation.

- Air Motors: Rotary motion, used in applications requiring high torque and speed.

Hydraulic Actuators

- Hydraulic Cylinders: High force and precision, used in applications requiring high pressure and load-bearing capabilities.

- Hydraulic Motors: Rotary motion, used in applications requiring high torque and precision.

3. How do you ensure the safety of robotic systems?

Ensuring the safety of robotic systems is crucial to prevent accidents and protect both humans and equipment. Here are some key practices:

- Risk Assessment: Conducting thorough risk assessments to identify potential hazards and implement appropriate safety measures.

- Guarding and Barriers: Installing physical barriers and guards to prevent human contact with hazardous areas.

- Emergency Stop Systems: Providing easily accessible emergency stop buttons to quickly halt robotic operations in case of an emergency.

- Sensor Integration: Utilizing sensors to detect obstacles, monitor system status, and trigger safety mechanisms.

- Training and Procedures: Providing comprehensive training to operators and maintenance personnel to ensure proper operation and emergency response.

4. What are the advantages of using simulation in robotic applications?

Simulation offers numerous benefits in robotic applications, including:

- Testing and Validation: Simulating robotic systems allows for rigorous testing and validation of control algorithms, motion planning, and system behavior.

- Reduced Development Time: Simulation enables rapid prototyping and iterative design, significantly reducing the development time for robotic systems.

- Safety Assessment: Simulation can be used to assess the safety of robotic systems in various scenarios, reducing the risk of accidents during real-world deployment.

- Training and Education: Simulations provide a safe and effective platform for training robot operators and researchers.

5. How do you handle errors and faults in robotic systems?

Handling errors and faults in robotic systems is critical to ensure reliable operation and prevent system failures. Here are some common approaches:

- Error Detection and Diagnosis: Implementing mechanisms to detect and diagnose errors and faults in real-time.

- Error Recovery: Developing strategies to recover from errors and faults gracefully, such as retry mechanisms or fail-safe modes.

- Fault Tolerance: Designing systems with redundant components or backup systems to maintain functionality in the event of a fault.

- Error Logging: Maintaining logs to record errors and faults for analysis and future troubleshooting.

6. What troubleshooting techniques do you use for robotic systems?

Troubleshooting robotic systems requires a systematic approach and a combination of techniques, including:

- Error Messages and Logs: Analyzing error messages and logs to identify the source of the problem.

- Visual Inspection: Checking for physical damage, loose connections, or other visible issues.

- Diagnostic Tools: Using specialized diagnostic tools to gather data and identify the root cause of the fault.

- Code Debugging: Stepping through code to identify logical errors or performance issues.

- Simulation: Running simulations to recreate the problem and test potential solutions.

7. How do you stay up-to-date with the latest advancements in robotics?

To stay current with the rapidly evolving field of robotics, I actively engage in the following practices:

- Attending Industry Conferences: Participating in conferences and workshops to learn about emerging technologies and research.

- Reading Technical Journals: Subscribing to robotics journals and publications to stay informed about the latest developments.

- Joining Professional Organizations: Becoming a member of professional organizations, such as IEEE Robotics and Automation Society, for networking and access to industry resources.

- Online Learning Platforms: Enrolling in online courses and tutorials to expand knowledge and skills.

8. What are your strengths and weaknesses as a Robotic Machine Operator?

Strengths

- Strong understanding of robotic systems, including motion control, actuators, and sensors.

- Experience in programming and operating robotic arms and manipulators.

- Excellent troubleshooting and problem-solving skills.

- Proficient in safety protocols and risk assessment for robotic operations.

- Ability to work independently and as part of a team.

Weaknesses

- Limited experience with specific industry-specific robotic applications.

- Still developing expertise in advanced simulation techniques for robotic systems.

9. What are your career goals and how does this position align with them?

My career goal is to become a highly skilled Robotic Machine Operator and contribute to the advancement of robotics technology. This position aligns perfectly with my aspirations as it provides an opportunity to:

– Gain hands-on experience in operating and maintaining robotic systems.

– Develop expertise in troubleshooting and optimizing robotic performance.

– Collaborate with engineers and technicians to improve robotic processes and applications.

– Stay at the forefront of robotic advancements and explore new and innovative solutions.

10. Why are you interested in working for our company?

I am eager to join your company because of its reputation as a leader in robotics innovation. Your commitment to research and development, coupled with the opportunity to work with cutting-edge technologies, makes this position highly appealing. I believe that my skills and experience would be a valuable asset to your team, and I am confident that I can make significant contributions to your ongoing success in the field of robotics.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Robotic Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Robotic Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Robotic Machine Operators are responsible for operating, monitoring, and maintaining robotic machines in various industrial settings. They play a crucial role in the production process by ensuring the efficient and safe functioning of these machines.

1. Machine Operation

Operate robotic machines according to established programs and procedures.

- Load and unload workpieces into the machine.

- Monitor machine performance and adjust parameters as needed.

2. Machine Maintenance

Perform routine maintenance and inspections on robotic machines.

- Clean and lubricate machines.

- Identify and troubleshoot minor issues.

3. Quality Control

Inspect finished products for defects and ensure they meet quality standards.

- Use measuring tools and gauges to verify accuracy.

- Reject non-conforming products.

4. Safety and Compliance

Follow all safety protocols and regulations related to the operation of robotic machines.

- Wear appropriate personal protective equipment.

- Report any unsafe conditions or practices.

Interview Tips

Preparing for an interview for a Robotic Machine Operator position requires a combination of technical knowledge and soft skills. Here are some tips to help you ace the interview:

1. Research the Company and Position

Thoroughly research the company and the specific role you are applying for. This will give you a better understanding of the company’s culture, products, and the specific responsibilities of the position.

2. Highlight Your Technical Skills

Emphasize your technical skills related to robotic machine operation, maintenance, and troubleshooting. Provide examples of your experience in operating and troubleshooting robotic machines, and how you have contributed to improving efficiency and productivity.

3. Showcase Your Attention to Detail

Robotic Machine Operators must have a keen eye for detail to ensure the accuracy and quality of finished products. Highlight your attention to detail by providing examples of how you have identified and corrected errors in your previous roles.

4. Demonstrate Safety Awareness

Safety is paramount when working with robotic machines. Emphasize your knowledge of safety protocols and regulations related to the operation of robotic machines. Share examples of how you have maintained a safe work environment and followed safety procedures.

5. Practice Common Interview Questions

Practice answering common interview questions such as “Tell me about yourself,” “Why are you interested in this position?” and “What are your strengths and weaknesses?” Prepare thoughtful and concise answers that highlight your qualifications and enthusiasm for the role.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Robotic Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Robotic Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.