Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Welding Robot Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Welding Robot Operator so you can tailor your answers to impress potential employers.

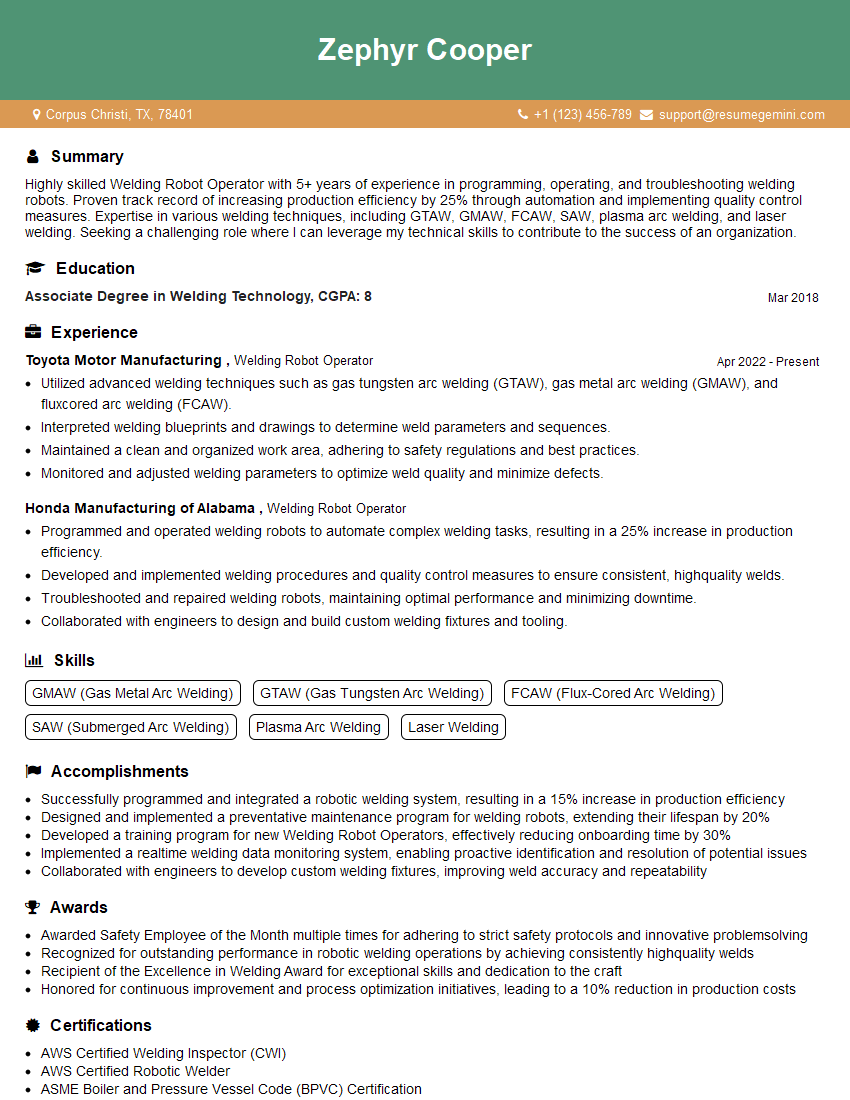

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Welding Robot Operator

1. How do you ensure the accuracy of the robot’s welding process?

To ensure the accuracy of the robot’s welding process, I employ the following measures:

- Regularly calibrate the robot to maintain its precision.

- Inspect and maintain the welding head to prevent any operational issues.

- Use high-quality materials and follow industry standards for welding parameters.

2. Explain the different welding techniques used by robots.

Robots can perform various welding techniques, including:

- Gas Metal Arc Welding (GMAW): Uses a shielding gas to protect the weld pool from contamination.

- Gas Tungsten Arc Welding (GTAW): Employs a tungsten electrode to create an arc, resulting in high-quality welds.

- Laser Welding: Utilizes a focused laser beam to melt and fuse metals together.

- Resistance Welding: Generates heat through electrical resistance at the joint.

3. How do you troubleshoot common errors encountered during robotic welding?

To troubleshoot common errors during robotic welding, I follow a systematic approach:

- Identify the error code: Analyze the robot’s display or system logs to determine the specific error.

- Check for physical issues: Inspect the welding head, cables, and other components for damage or loose connections.

- Review welding parameters: Ensure that the settings for voltage, amperage, and speed are appropriate for the material and joint design.

4. Describe the safety precautions you take when working with robotic welding systems.

When working with robotic welding systems, I strictly adhere to the following safety precautions:

- Wear appropriate PPE: Including welding helmet, gloves, and protective clothing.

- Ensure proper ventilation: To remove fumes and gases generated during the welding process.

- Follow lockout/tagout procedures: To prevent accidental activation of the robot.

- Maintain a safe work area: Free from clutter and potential hazards.

5. How do you optimize welding speed and efficiency without compromising quality?

To optimize welding speed and efficiency without compromising quality, I employ the following strategies:

- Selecting the appropriate welding parameters: Based on the material, joint design, and desired weld quality.

- Using advanced welding techniques: Such as pulsed or modulated welding to increase deposition rates.

- Automating repetitive tasks: Programming the robot to perform consistent and accurate welds.

- Minimizing downtime: By performing regular maintenance and troubleshooting issues promptly.

6. How do you ensure the quality of welds produced by the welding robot?

To ensure the quality of welds produced by the welding robot, I implement the following measures:

- Visual inspection: Examining the welds for proper penetration, shape, and surface finish.

- Non-destructive testing (NDT): Using methods such as ultrasonic testing or radiographic inspection to detect internal defects.

- Compliance with standards: Adhering to industry standards and specifications for weld quality.

7. How do you handle welding different materials, such as steel, aluminum, and stainless steel?

I have experience in welding a variety of materials, including:

- Steel: Using the appropriate welding process and parameters to achieve strong and durable welds.

- Aluminum: Employing specialized techniques to prevent oxidation and ensure weld integrity.

- Stainless steel: Utilizing specific welding consumables and techniques to maintain corrosion resistance.

8. How do you stay updated with the latest advancements in robotic welding technology?

To stay updated with the latest advancements in robotic welding technology, I engage in the following activities:

- Attending industry conferences and workshops: To learn about new developments and best practices.

- Reading technical journals and articles: To stay informed about emerging technologies and research.

- Participating in online forums and discussions: To connect with other professionals and exchange knowledge.

9. Explain how you would approach programming a welding robot to perform a complex weld sequence.

To program a welding robot for a complex weld sequence, I follow these steps:

- Analyze the weld joint geometry and determine the required process parameters: This includes identifying the welding technique, travel speed, and power settings.

- Create a robot program using a programming language or software: Defining the robot’s movements, welding parameters, and any necessary logic.

- Simulate and test the program: Using simulation software or physical testing to validate the accuracy and efficiency of the program.

- Optimize the program for speed and quality: By adjusting parameters and implementing advanced programming techniques.

10. How do you maintain and calibrate a welding robot to ensure optimal performance?

I ensure optimal performance of a welding robot by adhering to a comprehensive maintenance and calibration schedule:

- Regular cleaning and inspection: To remove debris and identify potential issues.

- Calibration of axes and sensors: Using precision instruments to ensure accuracy and repeatability.

- Checking for software updates: To implement bug fixes and performance enhancements.

- Preventive maintenance: Replacing worn or damaged components to prevent breakdowns.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Welding Robot Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Welding Robot Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Welding Robot Operator is responsible for the operation, maintenance, and repair of welding robots. They work in a variety of industries, including automotive, aerospace, and construction. Key job responsibilities include:

1. Preparation

Setting up and calibrating welding robots

- Loading and unloading workpieces

- Monitoring welding parameters

2. Operation

Operating welding robots to weld metal components

- Ensuring that welds meet quality standards

- Troubleshooting and resolving welding problems

3. Maintenance

Performing preventive maintenance on welding robots

- Cleaning and lubricating robots

- Replacing worn parts

4. Repair

Repairing welding robots

- Diagnosing and troubleshooting robot malfunctions

- Replacing defective parts

Interview Tips

Preparing for an interview for a Welding Robot Operator position can be daunting, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace your interview:

1. Research the Company and the Position

Take some time to learn about the company you’re interviewing with and the specific position you’re applying for. This will help you answer questions intelligently and show that you’re genuinely interested in the opportunity.

- Visit the company website

- Read industry news and articles

- Talk to people in your network who work in the field

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Prepare your answers to these questions in advance so that you can deliver them confidently and concisely.

- Use the STAR method when answering interview questions

- Be specific and provide examples

- Tailor your answers to the specific position and company

3. Be Prepared to Talk About Your Experience and Skills

The interviewer will want to know about your experience and skills as a Welding Robot Operator. Be prepared to talk about your previous work experience, any relevant training or certifications you have, and your key skills and abilities.

- Quantify your accomplishments whenever possible

- Highlight your strengths and how they relate to the position

- Be prepared to discuss your weaknesses and how you’re working to improve them

4. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally for your interview. Arrive on time and be prepared to make a good impression. Be polite and respectful to everyone you meet, including the receptionist and other employees.

- Choose clothing that is clean, pressed, and appropriate for the work environment

- Arrive 10-15 minutes early for your interview

- Be polite and respectful to everyone you meet

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Welding Robot Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Welding Robot Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.