Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Computer Numerical Control Process Control Programmer (CNC Process Control Programmer) position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

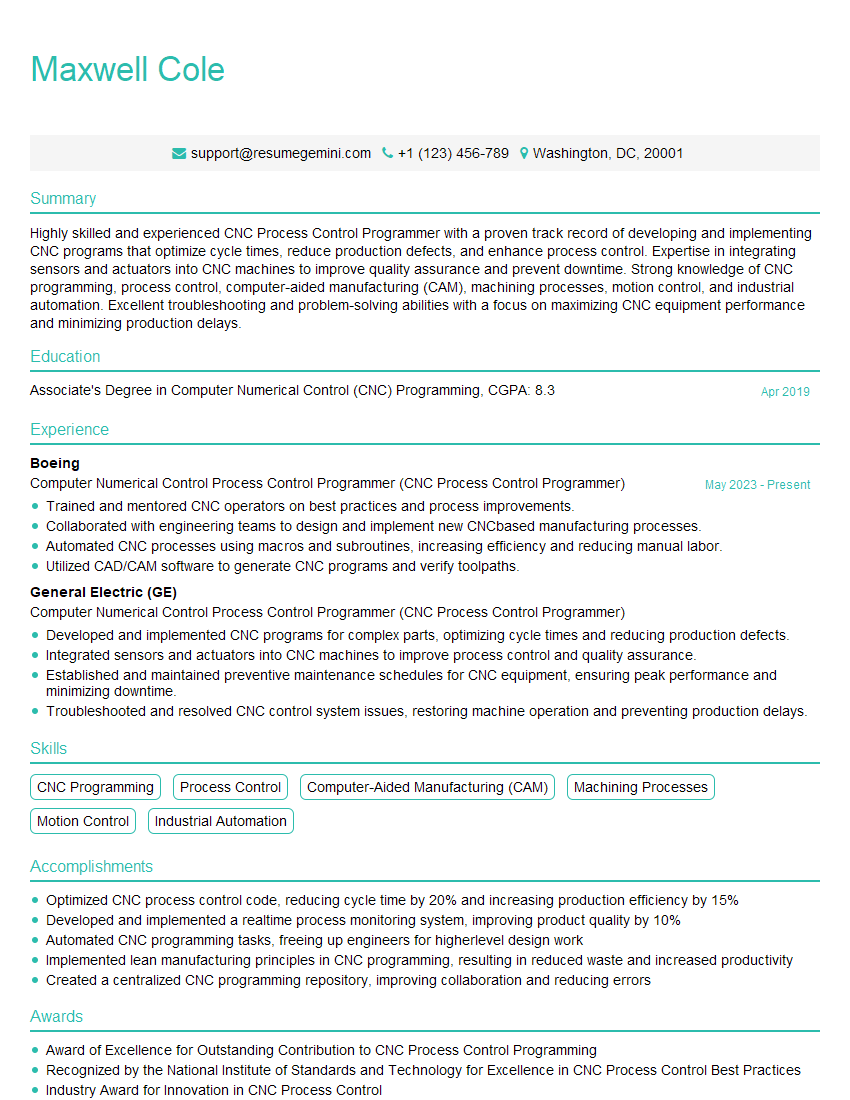

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Computer Numerical Control Process Control Programmer (CNC Process Control Programmer)

1. What are the different types of CNC control systems?

In answering this question, the candidate should provide detailed information about various CNC control systems, their functionalities, and their applications. Here is an example of a sample answer:

- Open-loop control systems: These systems do not use feedback to correct errors. Instead, they rely on the accuracy of the machine and the program to produce the desired results. Open-loop control systems are typically used for simple applications where accuracy is not critical.

- Closed-loop control systems: These systems use feedback to correct errors. This allows them to achieve greater accuracy than open-loop control systems. Closed-loop control systems are typically used for more complex applications where accuracy is critical.

- Computer numerical control (CNC) systems: These systems use computers to control the movement of the machine. CNC systems are typically used for complex applications where high accuracy and repeatability are required.

2. What are the advantages and disadvantages of using CNC machines?

Advantages

- Increased accuracy and precision

- Reduced labor costs

- Increased productivity

- Improved quality control

- Reduced setup time

Disadvantages

- High initial investment cost

- Requires skilled operators

- Can be complex to program

- Maintenance costs can be high

3. What types of programming languages are used for CNC machines?

In answering this question, the candidate should list and provide a brief description of the different programming languages used for CNC machines. Here is an example of a sample answer:

- G-code: G-code is a widely used programming language for CNC machines. It is a high-level language that is easy to learn and use.

- M-code: M-code is a machine-specific programming language. It is used to control the auxiliary functions of the machine, such as coolant, spindle speed, and tool changes.

- APT: APT (Automatically Programmed Tools) is a high-level programming language that is used to generate G-code and M-code programs.

4. What are the different types of CNC machine tools?

In answering this question, the candidate should provide detailed information about different CNC machine tools, their functionalities, and their applications. Here is an example of a sample answer:

- CNC milling machines: These machines are used to cut and shape metal by rotating a cutting tool at high speeds.

- CNC lathes: These machines are used to turn metal by rotating the workpiece while a cutting tool cuts away at it.

- CNC grinders: These machines are used to grind metal by using a rotating abrasive wheel.

- CNC routers: These machines are used to cut and shape wood, plastic, and other materials by using a rotating cutting tool.

5. What are the safety precautions that must be taken when operating CNC machines?

In answering this question, the candidate should provide detailed information about the different safety precautions that must be taken when operating CNC machines. Here is an example of a sample answer:

- Wear appropriate safety gear, such as safety glasses, gloves, and earplugs.

- Never operate a CNC machine while under the influence of alcohol or drugs.

- Keep the work area clean and free of clutter.

- Never reach into the cutting area while the machine is running.

- Be aware of the location of all emergency stop buttons.

6. What are the different types of CNC controls?

In answering this question, the candidate should provide detailed information about different types of CNC controls, their functionalities, and their applications. Here is an example of a sample answer:

- Manual controls: These controls are used to manually operate the CNC machine. They are typically used for simple operations or for setting up the machine.

- Computer-aided manufacturing (CAM) controls: These controls are used to program and control the CNC machine using a computer. They are typically used for complex operations or for mass production.

- Direct numerical control (DNC) controls: These controls are used to transmit CNC programs directly to the machine from a computer. They are typically used for large-scale manufacturing operations.

7. What are the different types of CNC software?

In answering this question, the candidate should provide detailed information about different types of CNC software, their functionalities, and their applications. Here is an example of a sample answer:

- CAD/CAM software: This software is used to design and create CNC programs. It typically includes features for 3D modeling, toolpath generation, and simulation.

- CNC simulation software: This software is used to simulate the operation of a CNC machine. It can be used to verify CNC programs and to identify potential problems.

- CNC monitoring software: This software is used to monitor the operation of a CNC machine. It can be used to track production data, identify errors, and troubleshoot problems.

8. What are the different types of CNC applications?

In answering this question, the candidate should provide detailed information about different types of CNC applications, their functionalities, and their applications. Here is an example of a sample answer:

- Aerospace: CNC machines are used to manufacture a variety of aerospace components, such as aircraft wings, fuselage panels, and engine parts.

- Automotive: CNC machines are used to manufacture a variety of automotive components, such as engine blocks, cylinder heads, and transmission cases.

- Medical: CNC machines are used to manufacture a variety of medical devices, such as surgical instruments, implants, and prosthetics.

9. What are the future trends in CNC technology?

In answering this question, the candidate should provide detailed information about future trends in CNC technology, such as the use of artificial intelligence (AI), machine learning (ML), and the Internet of Things (IoT). Here is an example of a sample answer:

- Artificial intelligence (AI): AI is being used to develop CNC machines that can learn from experience and make decisions on their own.

- Machine learning (ML): ML is being used to develop CNC machines that can automatically identify and correct errors.

- Internet of Things (IoT): IoT is being used to develop CNC machines that can be connected to the internet and monitored remotely.

10. What are the different career paths for CNC programmers?

In answering this question, the candidate should provide detailed information about different career paths for CNC programmers, such as becoming a CNC programmer, a CNC machinist, or a CNC engineer. Here is an example of a sample answer:

- CNC programmer: CNC programmers write and edit CNC programs. They typically work in a manufacturing environment.

- CNC machinist: CNC machinists operate CNC machines. They typically work in a manufacturing environment.

- CNC engineer: CNC engineers design and develop CNC machines and systems. They typically work in a research and development environment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Computer Numerical Control Process Control Programmer (CNC Process Control Programmer).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Computer Numerical Control Process Control Programmer (CNC Process Control Programmer)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Computer Numerical Control (CNC) Process Control Programmers are responsible for developing, maintaining, and troubleshooting CNC programs that control the operation of CNC machines. Their key responsibilities include:1. Developing CNC Programs

Writing and editing CNC programs using specialized software, ensuring that they are accurate and efficient.

- Analyzing engineering drawings and specifications to determine the required CNC program parameters.

- Selecting and configuring appropriate cutting tools, speeds, and feeds based on material properties and machine capabilities.

2. Maintaining CNC Programs

Updating and modifying existing CNC programs to optimize performance and address any issues that may arise.

- Monitoring CNC machine performance and identifying areas for improvement.

- Making adjustments to CNC programs to increase efficiency, reduce cycle times, and improve product quality.

3. Troubleshooting CNC Programs

Diagnosing and resolving problems with CNC programs and machine operation.

- Identifying and correcting errors in CNC programs, such as syntax errors, logic errors, and incorrect parameters.

- Analyzing machine performance data to identify potential issues and implement corrective actions.

4. Collaborating with Other Departments

Working closely with engineers, production staff, and quality control personnel to ensure that CNC programs meet the required specifications and production targets.

- Providing technical support and training to operators and maintenance staff.

- Participating in process improvement initiatives and implementing new technologies to enhance CNC operations.

Interview Tips

Preparing thoroughly for an interview is crucial for success. Here are some tips to help you ace your CNC Process Control Programmer interview:

1. Research the Company and the Role

Familiarize yourself with the company’s background, industry, products or services, and company culture. Research the specific role you are applying for and understand its responsibilities, requirements, and challenges.

2. Highlight Your Technical Skills

Emphasize your proficiency in CNC programming software, CNC machine operation, and troubleshooting techniques. Showcase your ability to write, edit, and interpret CNC programs, as well as your experience in developing and optimizing CNC processes.

3. Demonstrate Problem-Solving Abilities

Explain your approach to troubleshooting CNC programs and machine issues. Provide examples of how you have successfully resolved problems in the past, highlighting your analytical thinking, problem-solving skills, and attention to detail.

4. Prepare for Industry-Specific Questions

Research industry trends, advancements in CNC technology, and best practices in CNC programming. Be prepared to discuss your views on these topics and how they can impact your work as a CNC Process Control Programmer.

5. Show Your Enthusiasm and Passion

Let the interviewer know why you are passionate about CNC programming and what motivates you to excel in this field. Express your desire to contribute your skills and experience to the company’s success.

6. Ask Thoughtful Questions

Prepare insightful questions to ask the interviewer about the company, the role, the team, and the industry. This demonstrates your interest and engagement in the position and the company.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Computer Numerical Control Process Control Programmer (CNC Process Control Programmer) role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.