Feeling lost in a sea of interview questions? Landed that dream interview for Extrusion Press Adjuster but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Extrusion Press Adjuster interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

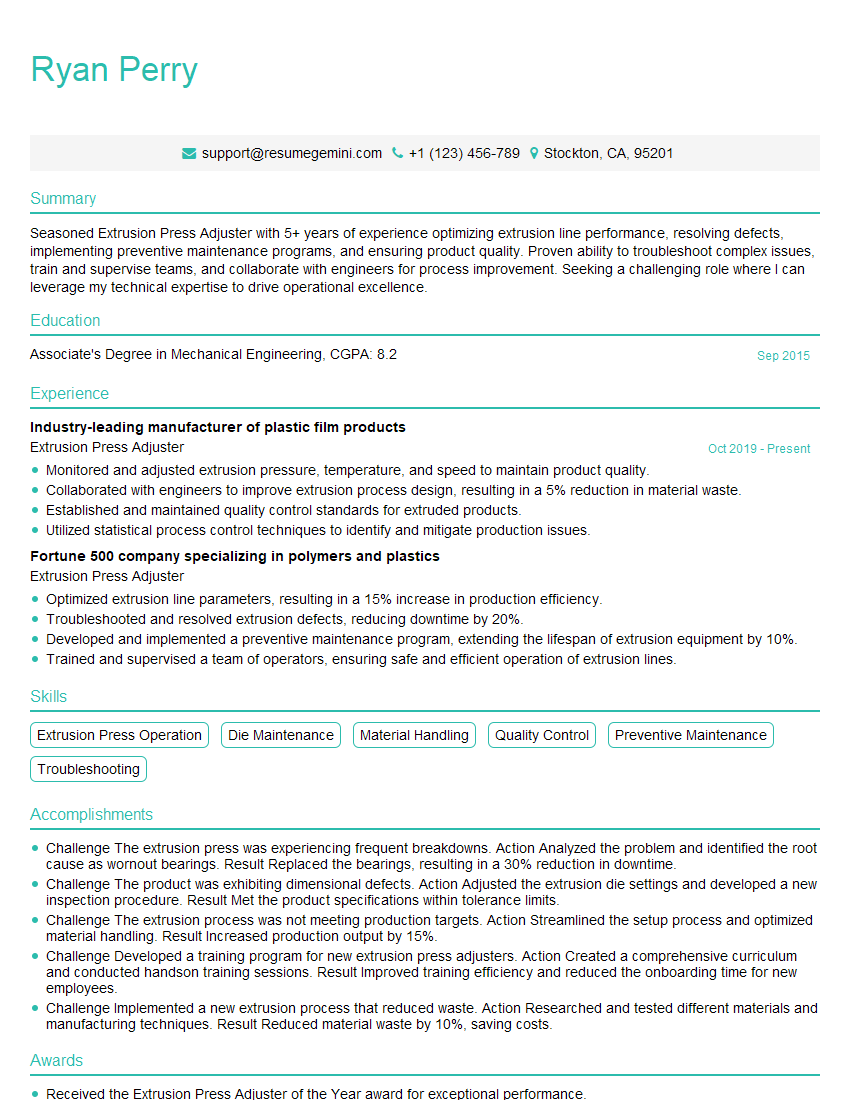

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Extrusion Press Adjuster

1. What are the key responsibilities of an Extrusion Press Adjuster?

The primary responsibilities of an Extrusion Press Adjuster typically include:

- Operating and adjusting extrusion presses to produce various plastic and rubber products

- Monitoring and controlling the extrusion process to ensure optimal product quality

2. Describe the extrusion process and the different types of extrusion machines.

Extrusion Process

- Melting or softening the raw material

- Forcing the material through a shaped die

- Cooling and solidifying the extruded product

Types of Extrusion Machines

- Single-screw extruders

- Twin-screw extruders

- Multi-screw extruders

3. How do you troubleshoot and resolve common issues related to extrusion presses?

Common issues and troubleshooting steps include:

- Blocked die: Clean or replace the die

- Material flow problems: Check material feed rate, temperature, and viscosity

- Product quality issues: Adjust process parameters, such as pressure, temperature, and speed

4. What are the safety protocols and preventative maintenance measures for extrusion presses?

Safety Protocols

- Wear appropriate personal protective equipment

- Follow lockout/tagout procedures

- Inspect equipment before use

Preventative Maintenance

- Regularly clean and lubricate equipment

- Inspect and replace worn or damaged parts

- Monitor equipment performance and adjust settings as needed

5. How do you ensure the production of high-quality extruded products?

To ensure high-quality products:

- Monitor process parameters and make adjustments as needed

- Inspect products regularly and identify any defects

- Calibrate equipment regularly to ensure accuracy

6. What experience do you have with different types of extrusion materials, such as plastics and rubbers?

Provide details on:

- Types of materials worked with

- Specific extrusion techniques used

- Challenges encountered and how they were resolved

7. Describe a complex extrusion project that you have successfully managed.

Highlight:

- The type of product being extruded

- The challenges encountered and how they were overcome

- The results achieved

8. How do you stay updated on the latest advancements in extrusion technology?

Mention:

- Industry publications and conferences attended

- Training courses or certifications obtained

- Networking with other professionals in the field

9. What are your strengths and weaknesses as an Extrusion Press Adjuster?

Strengths

- Strong technical skills and knowledge of extrusion processes

- Ability to troubleshoot and resolve issues efficiently

- Attention to detail and commitment to quality

Weaknesses

- Less experience with certain types of extrusion materials

- Need to improve communication skills with other team members

10. Why are you interested in this Extrusion Press Adjuster position at our company?

Tailor your answer to the specific company and position, highlighting:

- Your interest in the company’s products or services

- The company’s reputation in the industry

- The growth opportunities within the organization

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Extrusion Press Adjuster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Extrusion Press Adjuster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Extrusion Press Adjuster is responsible for operating, monitoring, and maintaining extrusion presses used in various manufacturing processes. Their primary objective is to produce high-quality extruded products efficiently and in accordance with specified requirements.

1. Machine Operation and Monitoring

Operate extrusion presses to produce products such as plastic pipes, tubes, sheets, and profiles.

- Set up and adjust extrusion press parameters, including temperature, pressure, and speed.

- Monitor machine performance and make adjustments as needed to maintain optimal production.

- Identify and troubleshoot any operational issues promptly to minimize downtime.

2. Quality Control

Conduct quality checks on extruded products to ensure they meet specifications.

- Inspect products for defects, such as dimensional accuracy, surface finish, and material properties.

- Collect and record production data to monitor product quality and identify areas for improvement.

- Implement corrective actions to address any quality issues.

3. Maintenance and Repair

Perform routine maintenance and repairs on extrusion presses to ensure optimal operation.

- Lubricate and clean machinery regularly to prevent equipment failures.

- Conduct preventive maintenance tasks to identify and repair potential problems before they escalate.

- Troubleshoot and repair mechanical, electrical, and hydraulic issues.

4. Safety and Compliance

Maintain a safe and compliant work environment.

- Adhere to all safety protocols and follow established operating procedures.

- Inspect machinery and work area for potential hazards and take appropriate precautions.

- Maintain a clean and organized work area to minimize the risk of accidents.

Interview Tips

To prepare effectively for an Extrusion Press Adjuster interview, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s operations, products, and industry trends. This will enable you to speak intelligently about your qualifications and how you align with the company’s goals.

- Visit the company website and social media pages.

- Read industry publications and news articles.

2. Practice Your Skills and Examples

Demonstrate your proficiency in operating, monitoring, and maintaining extrusion presses. Provide specific examples of how you have successfully resolved operational issues, improved product quality, and implemented safety measures.

- Review your past experiences and identify key accomplishments.

- Prepare answers to common interview questions using the STAR method (Situation, Task, Action, Result).

3. Highlight Your Safety Awareness

Emphasize your commitment to safety and your understanding of safety protocols in the extrusion industry. Explain how you have maintained a safe work environment and addressed potential hazards in your previous roles.

- Describe your experience in implementing safety procedures and training team members.

- Discuss any certifications or training you have in safety-related areas.

4. Showcase Your Problem-Solving Ability

Extrusion press adjusters are often faced with unexpected issues. Highlight your ability to identify and solve problems effectively. Share examples of how you have diagnosed and repaired equipment malfunctions, improved production efficiency, or resolved quality issues.

- Emphasize your analytical skills and attention to detail.

- Describe how you have used troubleshooting techniques to resolve complex problems.

Next Step:

Now that you’re armed with the knowledge of Extrusion Press Adjuster interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Extrusion Press Adjuster positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini