Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Hot Mill Observer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Hot Mill Observer so you can tailor your answers to impress potential employers.

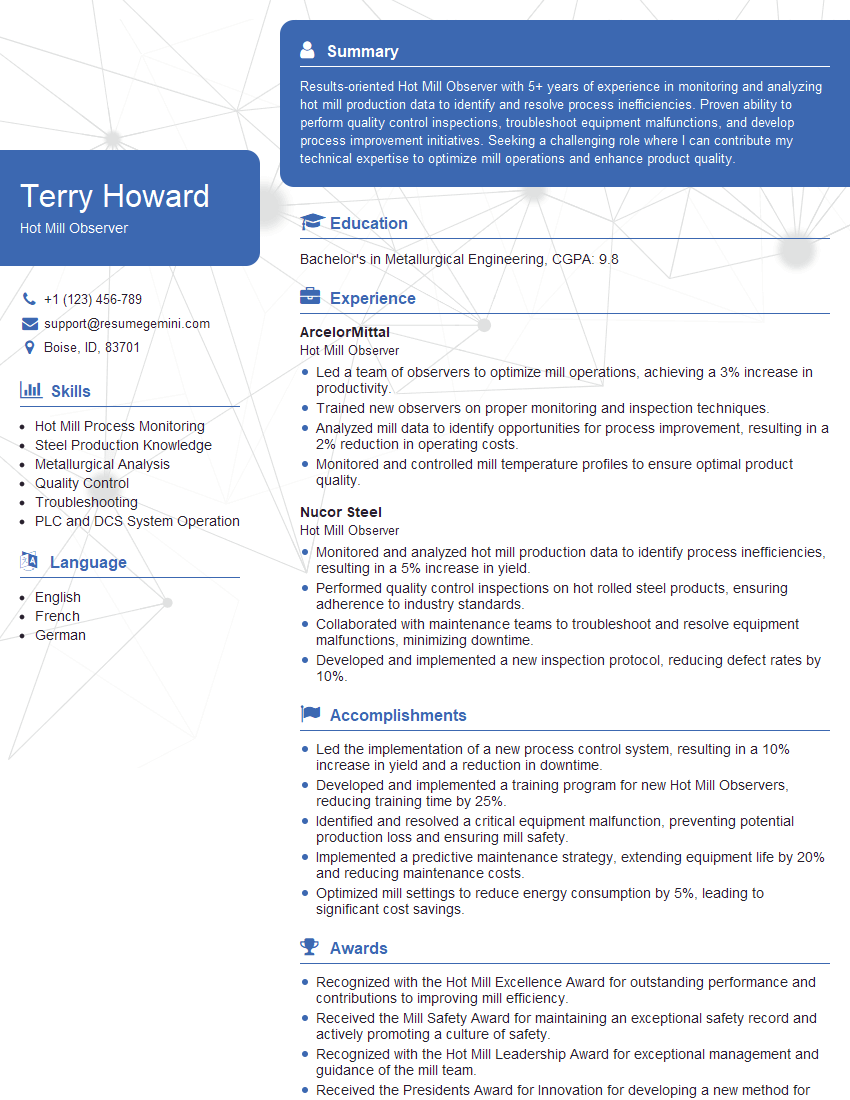

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hot Mill Observer

1. Explain the key responsibilities of a Hot Mill Observer?

As a Hot Mill Observer, my primary responsibilities include:

- Monitoring and observing the hot rolling process to ensure adherence to specifications

- Inspecting slabs, blooms, and hot-rolled coils for defects and quality issues

- Communicating with operators, supervisors, and quality control personnel to resolve issues and maintain production efficiency

- Maintaining accurate records of all observations and measurements

- Analyzing data and identifying areas for improvement in the hot rolling process

2. Describe the equipment and gauges used in the hot mill and their purposes?

Temperature Measurement Devices

- Thermocouples: Measure the temperature of slabs, blooms, and coils

- Infrared thermometers: Non-contact temperature measurement

Dimensional Measurement Devices

- Laser micrometers: Measure the thickness, width, and length of hot-rolled products

- Ultrasonic thickness gauges: Accurate thickness measurement without contact

Defect Detection Equipment

- Surface inspection machines: Detect defects such as cracks, scratches, and inclusions

- Ultrasonic testing: Non-destructive testing to identify internal defects

3. Explain how you identify and classify defects in hot-rolled steel products?

I classify defects based on their type, size, and location:

- Surface defects: Scratches, cracks, inclusions, and blisters

- Internal defects: Porosity, segregation, and voids

- Shape defects: Edge cracks, shape deviations, and thickness variations

4. How do you prioritize and respond to different types of defects in the hot mill?

Defects are prioritized based on their potential impact on product quality and safety:

- Critical defects: Immediately stop production and initiate corrective actions

- Major defects: Halt production until repairs are made

- Minor defects: Monitored and assessed to determine if they can be reworked or scrapped

5. Describe your understanding of the different hot rolling mill types and their applications?

- Reversing mills: Produce plates and sheets, offering flexibility in thickness and width

- Continuous mills: High-speed production of coils, used for automotive, construction, and appliance industries

- Sendzimir mills: Produce thin, high-quality strips used in electronic components and packaging

6. Explain how you maintain accurate records of your observations and measurements?

I use a combination of manual and automated systems:

- Manual logging: Record observations and measurements in a notebook or data sheets

- Electronic data collection: Use handheld devices or computerized systems to capture and store data

- Regular audits: Verify the accuracy and completeness of records

7. How do you analyze data and identify areas for improvement in the hot rolling process?

I use statistical techniques and process analysis tools to:

- Identify trends and patterns in defect occurrence

- Determine the root causes of defects

- Develop and implement corrective actions to reduce defects and improve quality

8. Describe your experience with hot mill process optimization and how you have contributed to improving efficiency and quality?

In my previous role, I worked on optimizing the hot rolling process by:

- Analyzing production data to identify bottlenecks and inefficiencies

- Developing and implementing process improvements to reduce cycle times and improve yield

- Collaborating with operators and engineers to implement new technologies and practices

9. Explain how you ensure compliance with quality standards and regulations in the hot mill environment?

I adhere to the following practices:

- Regular audits: Perform internal audits to ensure adherence to established standards

- Statistical process control: Monitor processes using statistical methods to identify and address deviations

- Training: Conduct training for operators on quality standards and procedures

10. How do you handle conflicts or disagreements with operators or supervisors in the hot mill?

I approach these situations professionally and respectfully by:

- Clearly communicating my observations and findings

- Listening to their perspectives and understanding their concerns

- Working collaboratively to find solutions that align with quality standards and production objectives

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hot Mill Observer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hot Mill Observer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Hot Mill Observer plays a critical role in steel production by monitoring the hot rolling process and ensuring the quality of the finished steel products.

1. Monitoring Rolling Operations

Observes the hot rolling process, including the temperature, speed, and tension of the steel.

- Ensures the rolling parameters meet specifications.

- Identifies and corrects deviations to optimize production.

2. Controlling Mill Equipment

Operates and monitors mill equipment, such as furnaces, rolling mills, and cooling systems.

- Adjusts equipment settings to achieve desired product dimensions and properties.

- Troubleshoots equipment malfunctions and performs minor repairs.

3. Quality Assurance

Inspects steel products for defects and verifies their compliance with quality standards.

- Uses measuring instruments and gauges to assess product dimensions, surface quality, and thickness.

- Reports any discrepancies to supervisors and initiates corrective actions.

4. Communication and Coordination

Collaborates with other mill personnel, including operators, engineers, and supervisors.

- Provides feedback on production issues and makes recommendations for improvements.

- Coordinates with other departments, such as quality control and maintenance.

Interview Tips

To ace the interview for a Hot Mill Observer position, it’s essential to prepare thoroughly and showcase your knowledge and skills.

1. Research the Company and Industry

Learn about the company’s operations, products, and reputation in the industry. Familiarize yourself with current trends and challenges in steel production.

- Visit the company website and social media pages.

- Read industry publications and news articles.

2. Highlight Your Technical Skills

Emphasize your understanding of hot rolling processes, equipment operation, and quality control techniques. Quantify your experience with specific instruments and equipment.

- Describe your experience in monitoring and controlling rolling parameters.

- Provide examples of how you have identified and resolved equipment issues.

3. Demonstrate Problem-Solving Abilities

Hot Mill Observers encounter various production issues, so it’s important to showcase your problem-solving skills. Provide examples of how you have analyzed problems, identified root causes, and implemented solutions.

- Share a situation where you faced a production problem and describe how you resolved it.

- Explain your approach to troubleshooting and the steps you take to prevent recurrence.

4. Emphasize Safety and Quality Consciousness

Hot Mill Observers play a vital role in ensuring the safety and quality of steel production. Highlight your commitment to these aspects.

- Describe your understanding of safety procedures and how you comply with them.

- Provide examples of how you have maintained a high level of product quality and identified potential defects.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hot Mill Observer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!