Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Grid Molder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

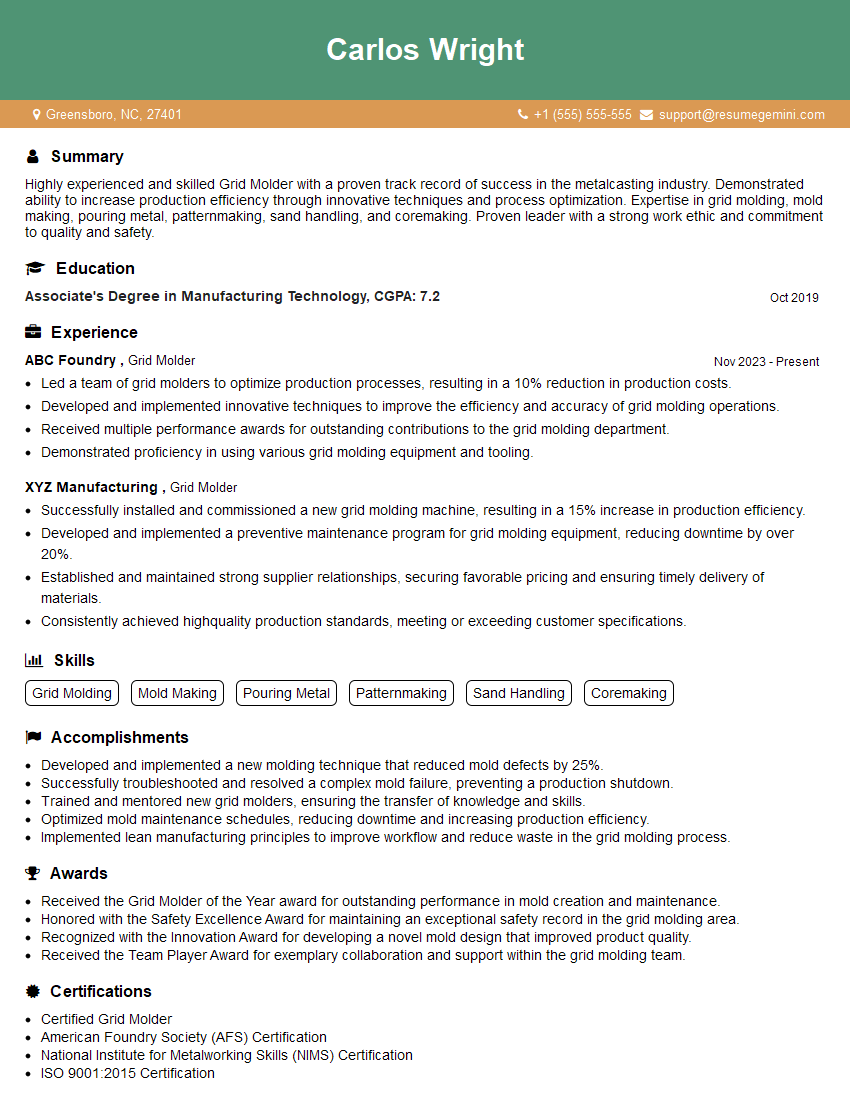

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Grid Molder

1. What are the key responsibilities of a Grid Molder?

As a Grid Molder, my primary responsibilities include the efficient operation of the grid molding machine, ensuring the production of high-quality grid castings that meet the specified requirements. This involves a comprehensive understanding of the molding process, machine functionality, and quality control procedures.

2. Describe the process of grid molding and the different types of molds used.

- Permanent Molds: These molds are made of metal and can be used multiple times. They are typically used for high-volume production.

- Semi-Permanent Molds: These molds are made of a combination of metal and sand. They can be used for medium-volume production.

- Expendable Molds: These molds are made of sand and are used for one-time use. They are typically used for low-volume production.

3. How do you maintain and calibrate the grid molding machine?

- Regularly inspect the machine for any wear or damage.

- Clean and lubricate the machine according to the manufacturer’s instructions.

- Calibrate the machine using precision measuring tools to ensure accurate dimensions.

4. What are the common defects that can occur during grid molding?

- Misruns: When the molten metal does not completely fill the mold cavity.

- Cold shuts: When the molten metal solidifies before it completely fills the mold cavity.

- Shrinkage cavities: When the molten metal shrinks as it cools, creating voids in the casting.

- Porosity: When gas bubbles are trapped in the molten metal, creating voids in the casting.

5. What are the safety precautions that must be observed when operating a grid molding machine?

- Wear appropriate personal protective equipment, including gloves, safety glasses, and a hard hat.

- Ensure that the machine is properly grounded.

- Keep the work area clean and free of debris.

- Follow the manufacturer’s operating instructions.

6. How do you troubleshoot common problems that may arise during grid molding?

- Identify the problem by observing the symptoms and gathering data.

- Consult the manufacturer’s documentation or consult with experienced colleagues.

- Implement corrective actions to resolve the problem.

- Document the problem and the solution for future reference.

7. What are the different grades of grid castings?

- Grade 1: High-quality castings with excellent surface finish and dimensional accuracy.

- Grade 2: Good-quality castings with acceptable surface finish and dimensional accuracy.

- Grade 3: Lower-quality castings with less stringent requirements for surface finish and dimensional accuracy.

8. How do you ensure the quality of grid castings?

- Inspect the castings for any defects or imperfections.

- Measure the castings to ensure they meet the specified dimensions.

- Perform non-destructive testing, such as radiography or ultrasonic testing, to detect any internal defects.

9. What are the advantages and disadvantages of using different molding materials?

Sand

- Advantages: Low cost, easy to form, high heat resistance

- Disadvantages: Not as strong as metal, can create rough surfaces

Metal

- Advantages: Strong, durable, precise

- Disadvantages: Expensive, difficult to form, not heat resistant

Ceramic

- Advantages: High heat resistance, corrosion resistance

- Disadvantages: Brittle, expensive

10. What are the latest advancements in grid molding technology?

- Automated molding machines: These machines can reduce labor costs and increase production efficiency.

- Vacuum molding: This process uses a vacuum to draw the molten metal into the mold cavity, reducing defects.

- 3D printing: This technology can be used to create complex mold shapes that are difficult to produce using traditional methods.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Grid Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Grid Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Grid Molder is a skilled professional responsible for operating and maintaining grid molding machines in a foundry or manufacturing environment. They are responsible for producing high-quality molds and cores for casting metal products.

1. Machine Operation

Grid Molders operate grid molding machines by following specific patterns. They use specialized tools and techniques to achieve the desired results.

- Set up and adjust the machine according to the mold specifications.

- Pour molten metal into the mold.

2. Mold Creation

They are responsible for creating molds and cores for casting metal products. This involves following specific patterns to ensure that the molds are accurate and meet the required specifications.

- Use various hand tools and equipment to create and assemble molds.

- Inspect and test molds and cores to ensure they meet specifications.

3. Maintenance and Troubleshooting

Grid Molders are also responsible for performing maintenance and troubleshooting on the grid molding machines. This involves cleaning, lubricating, and repairing the machines to ensure they are in good working order.

- Perform preventative maintenance and repairs on molding machines.

- Identify and resolve any issues that arise during the molding process.

4. Safety

Grid Molders must adhere to all safety regulations and procedures in the workplace. This includes wearing appropriate safety gear and following established safety protocols.

- Follow safety procedures and wear appropriate personal protective equipment.

- Maintain a clean and organized work area.

Interview Tips

Preparing for a job interview can be a daunting task, but there are some tips you can follow to increase your chances of success. Here are some interview tips and hacks that can help you ace your interview for a Grid Molder position.

1. Research the Company and Position

Before you go to your interview, it’s important to do your research on the company and the position you’re applying for. This will help you understand the company’s culture, values, and what they’re looking for in a Grid Molder.

- Visit the company’s website and read about their mission statement, values, and recent news.

- Check out the company’s social media pages to get a sense of their culture and values.

2. Practice Your Answers to Common Interview Questions

There are some common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s a good idea to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Brainstorm a list of common interview questions.

- Practice your answers out loud in front of a mirror.

3. Be Prepared to Talk About Your Experience

The interviewer will want to know about your experience as a Grid Molder. Be prepared to talk about your skills, experience, and accomplishments, and how they relate to the requirements in the job description.

- Highlight your experience in operating and maintaining grid molding machines.

- Emphasize your knowledge of different types of molds and cores.

4. Dress Professionally

It’s important to dress professionally for your interview. This shows the interviewer that you’re serious about the job and that you want to make a good impression.

- Wear a suit or other business attire.

- Make sure your clothes are clean and pressed.

5. Be Confident and Enthusiastic

The interviewer will be able to tell if you’re confident and enthusiastic about the job. Be yourself and show the interviewer that you’re excited about the opportunity to work at their company.

- Maintain eye contact with the interviewer.

- Speak clearly and confidently.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Grid Molder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!