Feeling lost in a sea of interview questions? Landed that dream interview for Job Molder but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Job Molder interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

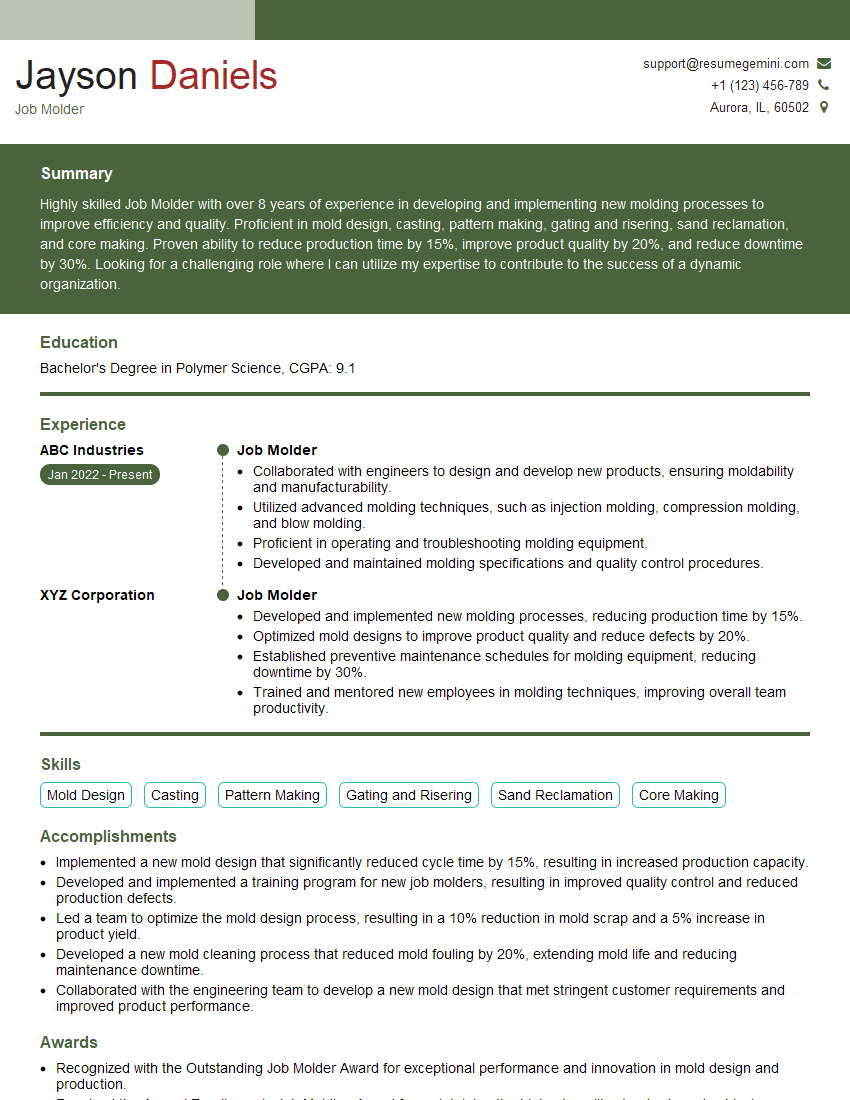

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Job Molder

1. What are the key characteristics of a good mold design?

- Robustness: The mold design should be able to withstand the rigors of the molding process, including high temperatures and pressures.

- Precision: The mold design should be precise enough to produce parts that meet the required specifications.

- Efficiency: The mold design should be efficient in terms of cycle time and material usage.

- Maintainability: The mold design should be easy to maintain and repair.

2. What are the different types of molding processes?

There are many different types of molding processes, including:

a) Injection molding:

- In this process, molten plastic is injected into a mold cavity under high pressure.

- Injection molding is a high-volume, automated process that is used to produce a wide variety of plastic parts.

b) Blow molding:

- In this process, molten plastic is blown into a mold cavity using compressed air.

- Blow molding is used to produce hollow plastic parts, such as bottles and containers.

c) Rotational molding:

- In this process, a mold is rotated while molten plastic is poured into it.

- Rotational molding is used to produce large, hollow plastic parts, such as toys and storage tanks.

3. What are the different types of mold materials?

- Steel: Steel is the most common mold material because it is strong, durable, and can withstand high temperatures.

- Aluminum: Aluminum is a lighter and less expensive alternative to steel, but it is not as strong or durable.

- Beryllium copper: Beryllium copper is a strong and durable material that is also resistant to corrosion.

- Plastic: Plastic is a less expensive alternative to metal, but it is not as strong or durable.

4. What are the different types of mold components?

The main components of a mold include:

a) Mold base:

- This is the foundation of the mold and provides support for the other components.

b) Mold cavity:

- This is the part of the mold that forms the shape of the part being produced.

c) Mold core:

- This is the part of the mold that forms the interior features of the part being produced.

d) Mold inserts:

- These are used to create specific features in the part being produced, such as threads or holes.

5. What are the different types of mold finishes?

- Polished: This finish is used to produce parts with a smooth, glossy surface.

- Textured: This finish is used to produce parts with a rough, textured surface.

- Matte: This finish is used to produce parts with a dull, non-glossy surface.

6. What are the different types of mold maintenance tasks?

Mold maintenance tasks include:

a) Cleaning:

- This is the most basic mold maintenance task and involves removing any dirt, debris, or other contaminants from the mold.

b) Inspection:

- This involves inspecting the mold for any signs of wear or damage.

c) Repair:

- This involves repairing any damage to the mold.

d) Calibration:

- This involves adjusting the mold to ensure that it is producing parts that meet the required specifications.

7. What are the different types of mold quality control procedures?

Mold quality control procedures include:

a) Dimensional inspection:

- This involves measuring the dimensions of the parts produced by the mold to ensure that they meet the required specifications.

b) Visual inspection:

- This involves inspecting the parts produced by the mold for any signs of defects.

c) Functional testing:

- This involves testing the parts produced by the mold to ensure that they function properly.

8. What are the different types of mold safety procedures?

Mold safety procedures include:

a) Proper use of safety equipment:

- This includes wearing appropriate clothing, safety glasses, and gloves when working with molds.

b) Proper handling of molds:

- This includes using proper lifting techniques and avoiding contact with sharp edges.

c) Proper storage of molds:

- This includes storing molds in a safe and dry location.

9. What are the different types of mold troubleshooting procedures?

Mold troubleshooting procedures include:

a) Identifying the problem:

- This involves determining the cause of the problem.

b) Developing a solution:

- This involves developing a plan to fix the problem.

c) Implementing the solution:

- This involves putting the plan into action.

d) Verifying the solution:

- This involves ensuring that the problem has been fixed.

10. What are the different types of mold design software?

There are many different types of mold design software available, including:

a) SolidWorks:

- This is a popular 3D CAD software program that can be used to create mold designs.

b) Catia:

- This is a powerful 3D CAD software program that can be used to create mold designs.

c) Siemens NX:

- This is a comprehensive 3D CAD software program that can be used to create mold designs.

d) Pro/ENGINEER:

- This is a popular 3D CAD software program that can be used to create mold designs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Job Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Job Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Job Molder is responsible for creating molds used in the production of metal castings, ceramics, and plastics. The Job Molder sets up and operates molding machines, inspects and maintains equipment, and ensures that the molds meet quality standards.

1. Mold Making

Job Molders create molds by pouring molten metal or plastic into a mold cavity, then allowing it to cool and solidify. Once the mold is set, the Job Molder removes it from the mold cavity and inspects it for defects.

- Creating and maintaining molds for casting processes

- Preparing and pouring molten metal or plastic into molds

- Inspecting and repairing molds to ensure accuracy and quality

2. Equipment Operation

Job Molders operate and maintain a variety of equipment, including molding machines, sand mixers, and cranes. They also maintain the work area and keep it clean and safe.

- Setting up and operating molding machines

- Maintaining and repairing equipment

- Ensuring a safe and efficient work environment

3. Quality Control

Job Molders inspect molds to ensure that they meet quality standards. They also inspect castings to ensure that they are free of defects.

- Inspecting molds and castings for defects

- Taking corrective action to correct any defects

4. Customer Service

Job Molders may also be responsible for providing customer service. They may answer questions about molds, castings, and the molding process. They may also help customers troubleshoot problems.

- Providing customer service and support

- Answering questions about products and services

- Resolving customer issues

Interview Tips

To ace your Job Molder interview, it is important to prepare thoroughly. Here are a few tips:

1. Research the Company and the Position

Before your interview, take some time to learn about the company and the position you are applying for. This will help you understand the company’s culture and the specific requirements of the job.

- Visit the company’s website

- Read the job description carefully

- Research the industry and the competition

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Prepare answers to common interview questions

- Practice your answers out loud

- Get feedback from a friend or family member

3. Be Prepared to Talk About Your Experience

The interviewer will want to know about your experience and how it relates to the position you are applying for. Be prepared to talk about your skills and accomplishments, and how they would benefit the company.

- Highlight your relevant skills and experience

- Use specific examples to demonstrate your abilities

- Quantify your accomplishments whenever possible

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are serious about the position and that you respect their time.

- Dress in business attire

- Arrive on time for your interview

- Be polite and respectful to everyone you meet

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Job Molder, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Job Molder positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.