Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Power Equipment Mechanics Instructor interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Power Equipment Mechanics Instructor so you can tailor your answers to impress potential employers.

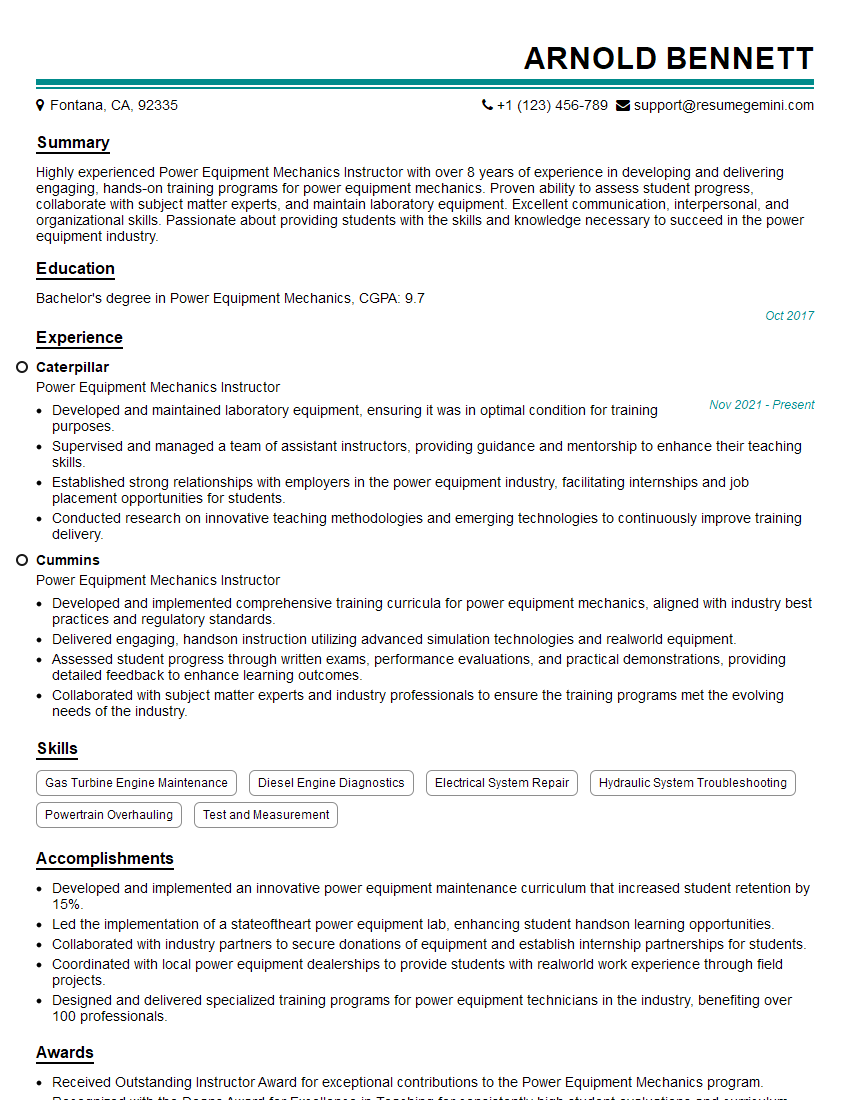

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Power Equipment Mechanics Instructor

1. What are the key components of a diesel engine and explain their functions?

- Cylinder: The cylindrical chamber where the combustion takes place.

- Piston: The movable part inside the cylinder that compresses the air-fuel mixture and powers the crankshaft.

- Crankshaft: The rotating shaft that converts the reciprocating motion of the piston into rotational motion.

- Connecting rod: The link between the piston and crankshaft that transfers the force of the piston’s movement.

- Camshaft: The shaft that controls the opening and closing of the valves.

- Valves: The devices that allow air, fuel, and exhaust gases to enter and exit the cylinder.

- Fuel injector: The device that sprays fuel into the cylinder.

- Turbocharger: The device that increases the air intake of the engine, boosting its power and efficiency.

2. Describe the different types of lubrication systems used in power equipment and their advantages and disadvantages.

Wet sump lubrication

- Advantages: Simple design, low cost, and reliable.

- Disadvantages: Oil can become contaminated, and oil capacity is limited.

Dry sump lubrication

- Advantages: Keeps oil clean, allows for a larger oil capacity, and provides better cooling.

- Disadvantages: More complex and expensive design.

Splash lubrication

- Advantages: Simple and inexpensive.

- Disadvantages: Not suitable for high-speed or high-load applications, and oil can become contaminated.

3. Explain the principles of hydraulic systems and how they are used in power equipment.

- Pascal’s principle: Pressure applied to a confined fluid is transmitted equally in all directions throughout the fluid.

- Hydraulic systems use this principle to transfer power and motion.

- Components of a hydraulic system: pump, reservoir, valves, hoses, and actuators.

- Applications in power equipment: power steering, brakes, lifting mechanisms, and attachments.

4. Discuss the safety precautions to take when repairing or maintaining power equipment.

- Disconnect the power source.

- Wear appropriate personal protective equipment (PPE) such as gloves, eye protection, and earplugs.

- Inspect the equipment for any damage or defects before operating it.

- Follow the manufacturer’s instructions for maintenance and repair procedures.

- Use proper tools and equipment for the job.

- Do not attempt repairs or maintenance unless you are qualified to do so.

5. Describe the troubleshooting process you would follow to diagnose a problem with a power equipment engine.

- Gather information: Observe the symptoms, check the fuel level and condition, inspect the spark plug, and listen for unusual noises.

- Test and inspect: Perform diagnostic tests on the engine components, such as compression test, spark test, and fuel pressure test.

- Analyze the results: Interpret the test results and identify the likely cause of the problem.

- Repair or replace: Make the necessary repairs or replacements to fix the engine.

- Test and verify: Test the engine after the repair to ensure it is operating properly.

6. Explain the importance of regular maintenance for power equipment and describe the recommended maintenance schedule.

- Regular maintenance prevents breakdowns, extends equipment life, and ensures optimal performance.

- Recommended maintenance schedule:

- Daily: Check fluid levels, inspect belts and hoses.

- Weekly: Clean air filters, lubricate moving parts.

- Monthly: Change oil and filter, inspect spark plugs.

- Yearly: Comprehensive inspection and servicing by a qualified technician.

7. Discuss the different transmission systems used in power equipment and their applications.

- Manual transmission: The operator manually shifts gears using a clutch and gear lever.

- Automatic transmission: The transmission automatically shifts gears based on engine speed and load.

- Hydrostatic transmission: Uses hydraulic fluid to transfer power from the engine to the wheels, providing smooth and variable speed control.

- CVT transmission: Similar to a hydrostatic transmission, but uses a continuously variable pulley system for even smoother and more efficient power transfer.

8. Describe the techniques used to diagnose and repair electrical problems in power equipment.

- Visual inspection: Check for loose connections, damaged wires, and burnt components.

- Electrical testing: Use a multimeter to check for voltage, continuity, and resistance.

- Circuit tracing: Follow the electrical circuit to identify the source of the problem.

- Component replacement: Replace any faulty components, such as switches, relays, or solenoids.

9. Explain the principles of combustion and how they apply to power equipment engines.

- Combustion: The chemical reaction between a fuel and oxygen, releasing heat and energy.

- In power equipment engines, combustion occurs in the cylinder.

- The fuel is mixed with air and compressed by the piston.

- The spark plug ignites the mixture, causing combustion and expansion of gases.

- The expanding gases drive the piston down, converting the thermal energy into mechanical energy.

10. Describe the principles of hydraulics and how they apply to power equipment systems.

- Hydraulics: The use of pressurized fluid to transmit power and motion.

- In power equipment, hydraulic systems are used for tasks such as lifting, steering, and braking.

- Components of a hydraulic system: pump, reservoir, valves, hoses, and actuators.

- Hydraulic fluid is pumped through the system, creating pressure.

- The pressure is used to actuate hydraulic cylinders or motors, which perform the desired functions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Power Equipment Mechanics Instructor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Power Equipment Mechanics Instructor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Power Equipment Mechanics Instructors are responsible for the training and development of students in the field of power equipment mechanics. They teach students the theory and practical skills necessary to work on power equipment, including generators, engines, and turbines. Power Equipment Mechanics Instructors also assess students’ progress and provide guidance and support to ensure their success.

1. Develop and deliver lesson plans

Power Equipment Mechanics Instructors develop and deliver lesson plans that align with the curriculum and learning objectives. They use a variety of teaching methods, including lectures, demonstrations, and hands-on activities.

- Plan and prepare lesson materials, including handouts, presentations, and assignments.

- Deliver engaging and informative lectures on power equipment mechanics principles and practices.

2. Assess student learning

Power Equipment Mechanics Instructors assess student learning through a variety of methods, including tests, quizzes, and projects. They provide feedback to students on their progress and help them to identify areas where they need improvement.

- Administer and grade tests, quizzes, and assignments to evaluate student understanding.

- Provide timely and constructive feedback to students on their academic performance.

3. Provide guidance and support

Power Equipment Mechanics Instructors provide guidance and support to students both inside and outside the classroom. They help students to develop their skills, knowledge, and confidence. They also serve as mentors and role models for students.

- Advise and counsel students on academic and career matters.

- Collaborate with other faculty and staff to provide a supportive learning environment.

4. Maintain a safe learning environment

Power Equipment Mechanics Instructors are responsible for maintaining a safe learning environment. They ensure that students follow safety procedures and that the equipment is in good working order.

- Enforce safety regulations and ensure that students adhere to proper lab protocols.

- Inspect and maintain equipment to ensure a safe and functional learning environment.

Interview Tips

Preparing thoroughly for an interview is crucial to showcasing your skills and making a positive impression on the hiring manager. Here are some tips to help you ace your interview for a Power Equipment Mechanics Instructor position:

1. Research the school and position

Before the interview, take the time to research the school and the position you are applying for. This will help you to understand the school’s mission, values, and curriculum. You should also learn as much as you can about the specific position you are applying for, including the job responsibilities and qualifications.

- Visit the school’s website to learn about its history, mission, and academic programs.

- Review the job description carefully to identify the key responsibilities and qualifications.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Prepare answers to common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?”.

- Use the STAR method to answer questions about your experience and skills.

3. Be prepared to talk about your teaching philosophy

As a Power Equipment Mechanics Instructor, you will be asked to share your teaching philosophy during the interview. This is an opportunity to explain your approach to teaching and learning, and to demonstrate your commitment to student success.

- Develop a clear and concise statement of your teaching philosophy.

- Be prepared to discuss your teaching methods and how you would apply them to the power equipment mechanics curriculum.

4. Be enthusiastic and passionate about teaching

Power Equipment Mechanics Instructors are passionate about teaching and helping students to learn. They are enthusiastic about their subject matter and are able to communicate their knowledge and skills effectively. If you are not passionate about teaching, it will be difficult to succeed in this role.

- Demonstrate your enthusiasm for teaching by sharing examples of your experience.

- Explain how you would motivate and engage students in the learning process.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Power Equipment Mechanics Instructor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!