Feeling lost in a sea of interview questions? Landed that dream interview for Drop Forge Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Drop Forge Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

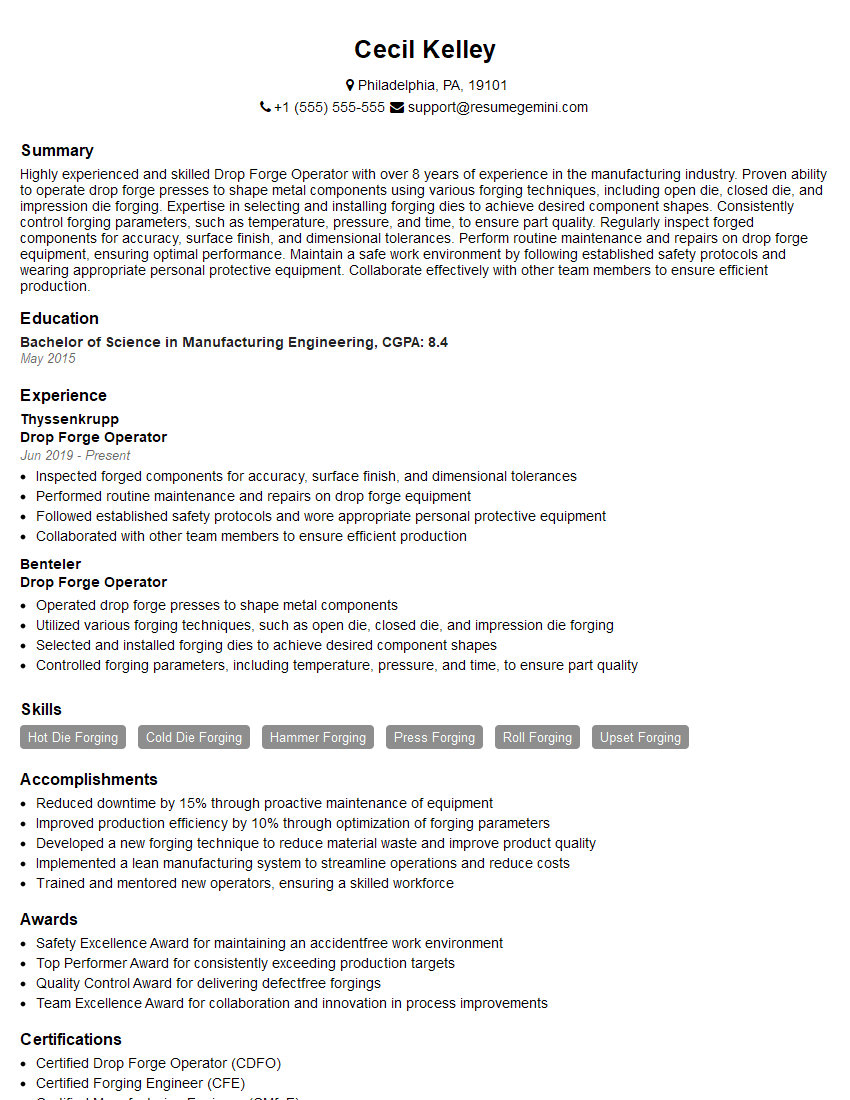

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Drop Forge Operator

1. Describe the process of drop forging?

In drop forging, the workpiece is placed between two dies, which are then struck by a hammer or press to shape the metal. The process can be used to produce a wide variety of shapes, from simple to complex.

- The process begins with heating the workpiece to a high temperature.

- The workpiece is then placed between the dies and struck by the hammer or press.

- The force of the blow causes the metal to flow into the shape of the dies.

- The part is then ejected from the dies and allowed to cool.

2. What are the different types of drop forging hammers?

There are two main types of drop forging hammers: gravity drop hammers and power drop hammers.

Gravity drop hammers

- Gravity drop hammers are powered by gravity, and the force of the blow is determined by the weight of the hammer.

- Gravity drop hammers are typically used for small to medium-sized parts.

Power drop hammers

- Power drop hammers are powered by a motor, and the force of the blow is controlled by the operator.

- Power drop hammers are typically used for larger parts.

3. What are the different types of drop forging dies?

There are two main types of drop forging dies: open dies and closed dies.

Open dies

- Open dies are used for forging parts that have a simple shape.

- Open dies do not completely enclose the workpiece, and the metal can flow out of the sides of the die.

Closed dies

- Closed dies are used for forging parts that have a complex shape.

- Closed dies completely enclose the workpiece, and the metal cannot flow out of the sides of the die.

4. What are the advantages of drop forging?

- Drop forging produces parts that are strong and durable.

- Drop forging can produce parts with a high degree of accuracy.

- Drop forging is a relatively fast and inexpensive process.

5. What are the disadvantages of drop forging?

- Drop forging can only be used to produce parts that have a relatively simple shape.

- Drop forging can produce parts that have a high degree of flash.

- Drop forging can be a noisy and dangerous process.

6. What are the safety precautions that must be taken when operating a drop forging hammer?

- Always wear proper safety gear, including safety glasses, gloves, and earplugs.

- Never operate a drop forging hammer if you are not properly trained.

- Always keep the work area clean and free of debris.

- Never place your hands or any other body parts in the path of the hammer.

- Always follow the manufacturer’s instructions for operating the drop forging hammer.

7. How do you maintain a drop forging hammer?

- Regularly inspect the hammer for wear and tear.

- Lubricate the hammer according to the manufacturer’s instructions.

- Replace any worn or damaged parts immediately.

8. What are the different types of materials that can be drop forged?

A wide variety of materials can be drop forged, including:

- Steel

- Aluminum

- Copper

- Brass

- Titanium

9. What are the different applications for drop forgings?

Drop forgings are used in a wide variety of applications, including:

- Automotive

- Aerospace

- Construction

- Agriculture

- Mining

10. What is the future of drop forging?

The future of drop forging is bright. Drop forging is a versatile and cost-effective process that can produce high-quality parts. As new technologies are developed, drop forging will continue to be a valuable manufacturing process.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Drop Forge Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Drop Forge Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Drop Forge Operators are responsible for operating and maintaining drop forge machines to shape metal components. They work in a variety of industries, including automotive, aerospace, and manufacturing.

1. Machine Operation

The primary responsibility of a Drop Forge Operator is to operate drop forge machines. These machines use a hammer or ram to strike a heated piece of metal, forcing it into a die to shape it. Operators must be able to control the machine’s speed, force, and timing to ensure that the metal is shaped correctly.

- Operate drop forge machines to shape metal components.

- Control the machine’s speed, force, and timing to ensure that the metal is shaped correctly.

- Monitor the machine’s operation and make adjustments as needed.

2. Die Maintenance

Drop Forge Operators are also responsible for maintaining the dies used in the forging process. Dies are precision-machined tools that must be kept in good condition to ensure that the metal is shaped correctly. Operators must be able to inspect dies for wear and tear, and to make repairs or replacements as needed.

- Inspect dies for wear and tear.

- Make repairs or replacements to dies as needed.

- Maintain a clean and organized work area.

3. Quality Control

Drop Forge Operators are responsible for ensuring that the metal components produced by the drop forge machine meet quality standards. They must be able to inspect components for defects, and to make adjustments to the machine or dies as needed to correct any problems.

- Inspect metal components for defects.

- Make adjustments to the machine or dies to correct any problems.

- Maintain records of production and quality control.

4. Safety

Drop Forge Operators work in a potentially hazardous environment. They must be familiar with all safety procedures and regulations, and must be able to work safely in a team environment.

- Follow all safety procedures and regulations.

- Work safely in a team environment.

- Wear appropriate personal protective equipment.

Interview Tips

Preparing for a job interview can be daunting, but there are a few things you can do to make the process easier and increase your chances of success.

1. Research the company and the position

Before you go to an interview, it is important to do your research and learn as much as you can about the company and the position you are applying for. This will help you to answer questions intelligently and show the interviewer that you are genuinely interested in the job.

- Visit the company’s website and read about their history, mission, and values.

- Look for news articles and press releases about the company.

- Talk to people you know who work for the company.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is a good idea to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Write out your answers to common interview questions.

- Practice saying your answers out loud.

- Get feedback from a friend or family member.

3. Be prepared to talk about your skills and experience

The interviewer will want to know what skills and experience you have that make you qualified for the position. Be prepared to talk about your skills and experience in detail, and to provide examples of how you have used them in the past.

- Make a list of your skills and experience.

- Prepare examples of how you have used your skills and experience in the past.

- Be able to articulate how your skills and experience make you qualified for the position.

4. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This will show the interviewer that you are serious about the job and that you respect their time.

- Dress in clean, pressed clothes that are appropriate for the job you are applying for.

- Arrive at the interview on time, or even a few minutes early.

- Be polite and respectful to everyone you meet.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Drop Forge Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!