Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Drophammer Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

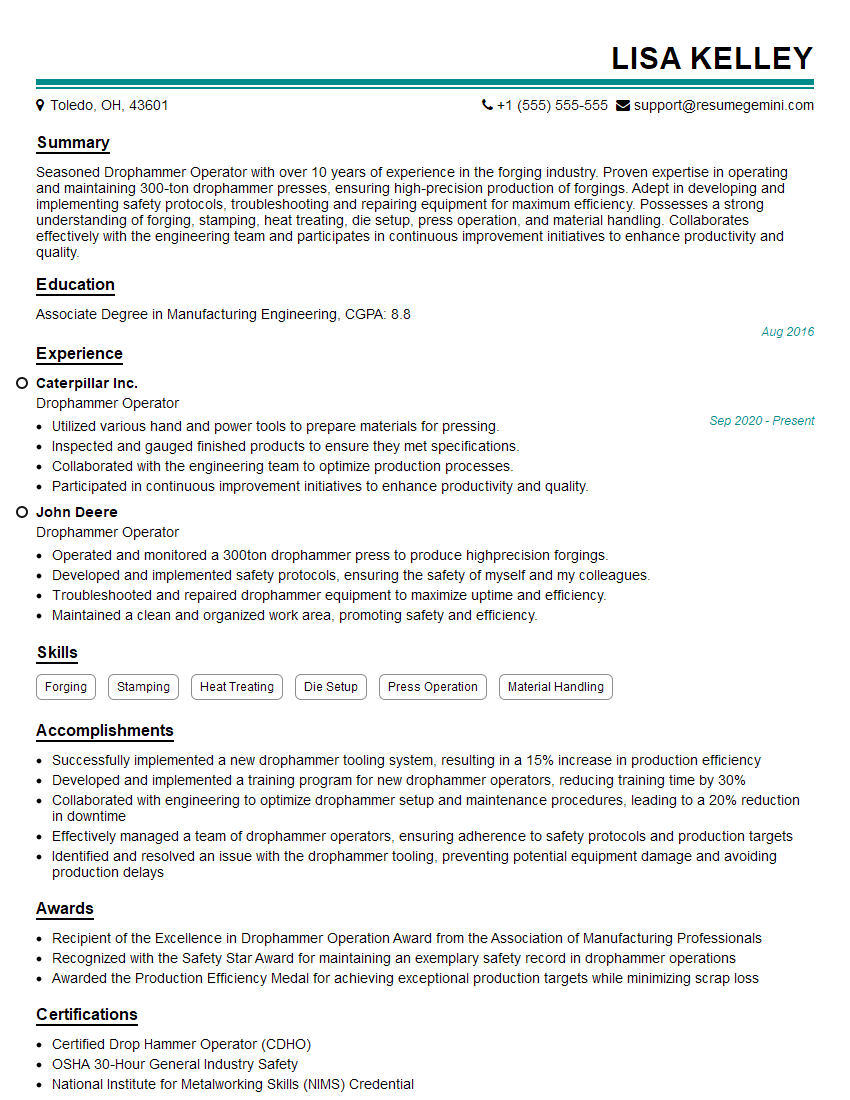

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Drophammer Operator

1. Describe the key responsibilities of a Drophammer Operator?

As a highly skilled Drophammer Operator I am responsible for several key tasks that contribute to the success of the manufacturing process. These responsibilities may vary depending on the company and industry, but some typical duties include:

- Operating and maintaining drop hammers to shape and form metal workpieces

- Using a variety of tools and equipment to set up, adjust, and operate drop hammers

- Inspecting raw materials and finished products to ensure quality standards are met

- Troubleshooting and resolving any issues that arise during the drop hammering process

- Following safety protocols and maintaining a clean and organized work area

2. What are the different types of drop hammers and their applications?

Mechanical Drop Hammers

- Powered by a motor and use a flywheel to generate the force needed to strike the workpiece

- Suitable for a wide range of materials and applications, including forging, stamping, and riveting

Hydraulic Drop Hammers

- Use hydraulic pressure to generate force

- Provide precise control over the force and speed of the blow

- Ideal for applications requiring high accuracy and repeatability, such as precision forging and stamping

Pneumatic Drop Hammers

- Use compressed air to generate force

- Lightweight and portable, suitable for smaller workpieces and applications where space is limited

- Often used in automotive and aerospace industries

3. How do you prevent accidents and maintain safety while operating a drop hammer?

Safety is of utmost importance when operating a drop hammer. I adhere to strict safety protocols to prevent accidents and maintain a safe work environment. Some key safety measures include:

- Wearing appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs, to minimize the risk of injury

- Ensuring that the drop hammer is properly set up and maintained to prevent malfunctions or accidents

- Inspecting the workpiece and surrounding area before each operation to identify any potential hazards

- Following lockout/tagout procedures to prevent accidental activation of the drop hammer

- Being aware of my surroundings and maintaining a safe distance from the drop hammer during operation

4. What are the common maintenance tasks required for a drop hammer?

Regular maintenance is crucial to ensure the optimal performance and longevity of a drop hammer. I perform various maintenance tasks to keep the equipment in good working condition, including:

- Lubricating moving parts to minimize friction and wear

- Inspecting and replacing worn or damaged components, such as dies, guides, and springs

- Checking the hydraulic or pneumatic system for leaks and ensuring proper pressure levels

- Cleaning the machine and work area to remove debris and prevent corrosion

- Performing regular inspections and adjustments to maintain accuracy and precision

5. How do you determine the correct die size and shape for a particular forming operation?

Selecting the appropriate die size and shape is critical to achieving the desired workpiece shape and dimensions. I consider several factors when determining the correct die, including:

- The geometry and dimensions of the desired workpiece

- The material properties of the workpiece, such as its thickness, hardness, and ductility

- The type of drop hammer being used and its capabilities

- The desired production rate and accuracy requirements

- Consulting with engineers or design teams to ensure the selected die meets the product specifications

6. What is the importance of die clearance in drop hammer operations?

Die clearance plays a vital role in drop hammer operations and directly affects the quality of the formed workpiece. I ensure proper die clearance to achieve the following:

- Preventing the workpiece from sticking to the dies and ensuring smooth release

- Allowing for material flow during forming to achieve the desired shape

- Minimizing wear and tear on the dies, extending their lifespan

- Maintaining dimensional accuracy and consistency in the formed workpieces

7. Describe the process of heat treating drop hammer dies.

Heat treating is an essential process for prolonging the life of drop hammer dies and improving their performance. I follow these steps when heat treating dies:

- Selecting the appropriate heat treatment method based on the die material and application

- Properly preparing the dies by cleaning and preheating them

- Heating the dies to a specific temperature in a controlled furnace

- Holding the dies at the desired temperature for a predetermined time to allow for structural changes

- Cooling the dies in a controlled manner to achieve the desired hardness and toughness

- Tempering the dies to relieve any internal stresses and improve their durability

8. How do you troubleshoot common problems that arise during drop hammer operations?

Troubleshooting is a critical skill for a Drophammer Operator. I have encountered various issues during my experience and have developed a systematic approach to troubleshooting:

- Identifying the problem and its symptoms

- Inspecting the drop hammer, dies, and workpiece for any visible defects or damage

- Checking the hydraulic or pneumatic system for leaks, pressure issues, or other malfunctions

- Consulting with more experienced operators or maintenance personnel if necessary

- Implementing appropriate corrective actions to resolve the problem

- Documenting the problem and the steps taken to resolve it for future reference

9. How do you ensure the quality of drop hammer formed parts?

Quality is paramount in drop hammer operations. I employ several methods to ensure the quality of formed parts:

- Inspecting raw materials before forming to identify any defects or inconsistencies

- Properly setting up and maintaining the drop hammer to minimize errors

- Using appropriate dies and die clearance to achieve the desired shape and dimensions

- Monitoring the forming process and making adjustments as needed

- Performing dimensional checks and other quality control tests on the formed parts

- Maintaining detailed records of production and quality control data

10. How do you stay updated on the latest technologies and best practices in drop hammer operations?

To stay current with the latest technologies and best practices in drop hammer operations, I engage in continuous learning and development activities:

- Attending industry conferences, workshops, and training programs

- Reading technical journals and articles related to drop hammer technology

- Consulting with experts in the field and sharing knowledge with colleagues

- Exploring innovative techniques and experimenting with different approaches to improve efficiency and quality

- Actively seeking opportunities to enhance my skills and knowledge

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Drophammer Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Drophammer Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Drophammer Operator is accountable for operating drophammers, which are machines used to shape metal. They are responsible for ensuring that the machines are functioning properly and producing high-quality products.

1. Operating Drophammers

The primary responsibility of a Drophammer Operator is to operate drophammers. This involves setting up the machine, loading the workpiece, and operating the controls to drop the hammer onto the workpiece. They must be able to adjust the machine settings to produce the desired results and ensure that the workpiece is shaped correctly.

- Set up and operate drophammers to shape metal workpieces.

- Control the speed and force of the hammer to create the desired shape.

2. Inspecting Workpieces

Drophammer Operators are also responsible for inspecting workpieces to ensure that they meet specifications. They must be able to identify any defects or imperfections and take corrective action as needed. They may also be responsible for maintaining records of the workpieces produced.

- Inspect workpieces for defects and ensure they meet specifications.

- Identify and correct any problems with the drophammer or workpieces.

3. Maintaining Equipment

Drophammer Operators are responsible for maintaining the equipment they use. This includes cleaning and lubricating the machines, and replacing worn or damaged parts. They must be able to troubleshoot problems with the equipment and make repairs as needed.

- Clean and lubricate drophammers and other equipment.

- Replace worn or damaged parts to ensure the equipment is in good working condition.

4. Safety

Drophammer Operators must always follow safety procedures when operating drophammers. This includes wearing proper safety gear and following all lockout/tagout procedures. They must be aware of the potential hazards of working with drophammers and take steps to avoid accidents.

- Follow all safety procedures and wear proper safety gear.

- Be aware of the potential hazards of working with drophammers.

Interview Tips

Here are some tips to help you ace your interview for a Drophammer Operator position:

1. Research the Company

Before your interview, take some time to research the company you are applying for. This will help you understand the company’s culture, values, and goals. You can also learn about the company’s products or services and its competition. This knowledge will help you answer questions about the company in a thoughtful and informed way.

- Visit the company’s website.

- Read the company’s blog and social media pages.

- Talk to people you know who work for the company.

2. Practice Your Answers

Once you have researched the company, take some time to practice your answers to common interview questions. This will help you sound confident and prepared during your interview. You can practice answering questions with a friend or family member, or you can practice on your own in front of a mirror.

- Prepare answers to questions about your experience, skills, and qualifications.

- Practice answering questions about your strengths and weaknesses.

- Be prepared to talk about your salary expectations.

3. Dress Professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting. You should also make sure your shoes are clean and polished.

- Wear a suit or dress pants and a button-down shirt.

- Make sure your clothes are clean and pressed.

- Wear closed-toe shoes.

4. Be Punctual

Punctuality shows that you are respectful of the interviewer’s time. Make sure you arrive at your interview on time, or even a few minutes early. If you are running late, call or email the interviewer to let them know.

- Plan your route to the interview in advance.

- Leave yourself plenty of time to get to the interview.

- If you are running late, call or email the interviewer to let them know.

5. Be Yourself

The most important thing is to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be honest and authentic, and let your personality shine through.

- Be honest and authentic.

- Let your personality shine through.

- Don’t try to be someone you’re not.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Drophammer Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!