Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Forge Hand interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Forge Hand so you can tailor your answers to impress potential employers.

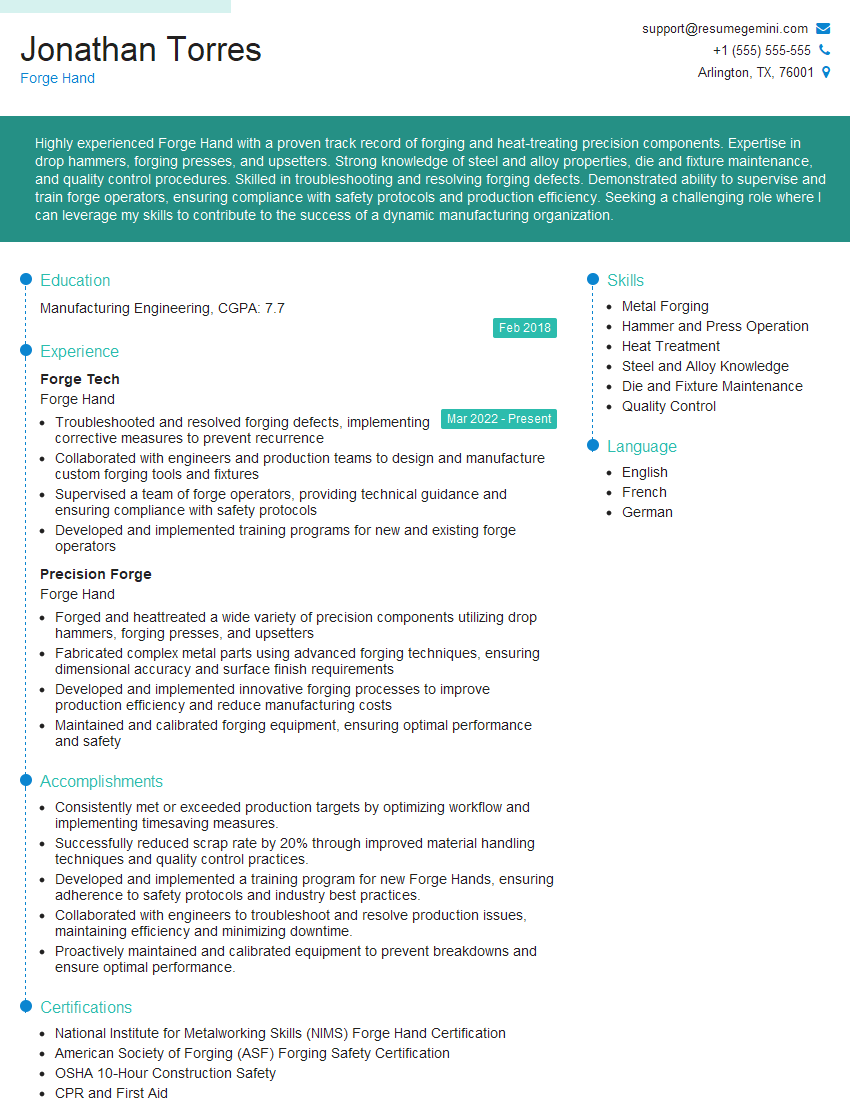

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Forge Hand

1. Explain the process of forging a metal component, including the steps involved and the equipment used?

- Annealing: Heat the metal to a high temperature, then cool it slowly to soften it.

- Forging: Use a hammer or press to shape the metal into the desired form.

- Normalizing: Heat the metal to a high temperature, then cool it in air to improve its strength and toughness.

- Tempering: Heat the metal to a lower temperature, then cool it in oil or water to increase its hardness.

2. What are the different types of forging processes? Discuss the advantages and disadvantages of each.

Open-die forging

- Advantages: allows for greater freedom of shape, can be used for large components.

- Disadvantages: less precise than closed-die forging, requires more skill from the operator.

Closed-die forging

- Advantages: more precise than open-die forging, can be used for smaller components.

- Disadvantages: requires more expensive tooling, can be less versatile than open-die forging.

Roll forging

- Advantages: can produce long, thin components with a high degree of precision.

- Disadvantages: requires specialized equipment, can be less versatile than other forging processes.

3. What are the key factors to consider when selecting a forging process?

- The shape and size of the component.

- The material of the component.

- The quantity of components to be produced.

- The cost of the forging process.

4. Describe the different types of forging tools and their uses?

- Anvils: Large, heavy blocks of metal used to support the workpiece during forging.

- Hammers: Heavy tools used to strike the workpiece and shape it.

- Forging presses: Machines used to apply pressure to the workpiece and shape it.

- Dies: Molds used to shape the workpiece during forging.

5. How do you ensure the quality of forged components?

- Visual inspection: Inspect the component for defects such as cracks, voids, and burrs.

- Dimensional inspection: Measure the component to ensure that it meets the specified dimensions.

- Hardness testing: Test the hardness of the component to ensure that it meets the specified requirements.

- Destructive testing: Perform destructive tests, such as tensile testing or impact testing, to evaluate the strength and toughness of the component.

6. What are the safety precautions that need to be taken when working with a forge?

- Wear appropriate safety gear, such as gloves, safety glasses, and earplugs.

- Keep the work area clean and free of tripping hazards.

- Use the forge only in a well-ventilated area.

- Never forge alone.

7. What are your strengths and weaknesses as a Forge Hand?

- Strengths: I am a highly skilled Forge Hand with over 10 years of experience in the industry. I am proficient in all types of forging processes, and I have a strong understanding of the metallurgy of metals. I am also a safety-conscious worker, and I always follow proper safety procedures.

- Weaknesses: I am not as experienced with some of the newer forging technologies, such as computer-controlled forging. I am also not as strong as some of the other Forge Hands in the shop.

8. Why are you interested in working as a Forge Hand for our company?

- I am interested in working as a Forge Hand for your company because I am impressed with your company’s reputation for quality and innovation. I believe that my skills and experience would be a valuable asset to your team.

- I am also interested in the opportunity to work with some of the newest forging technologies. I am confident that I can learn quickly and become a productive member of your team.

9. What are your salary expectations?

- My salary expectations are in line with the industry average for Forge Hands with my experience and skills.

- I am also willing to negotiate a salary that is based on my performance.

10. Do you have any questions for me?

- I am interested in learning more about the specific forging processes that your company uses.

- I am also interested in learning more about the company’s safety policies and procedures.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Forge Hand.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Forge Hand‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Forge Hand is a skilled professional responsible for operating and maintaining forging equipment such as hammers, presses, and manipulators in forge shops.

1. Forge Operation

Set up and operate forging equipment such as hammers, presses, and manipulators to shape and form metal stock.

- Control temperatures and pressures to ensure proper forging conditions.

- Monitor equipment for potential problems and make necessary adjustments.

2. Material Handling

Load, unload, and move metal stock, dies, and fixtures in the forge shop.

- Coordinate with other team members to ensure efficient material flow.

- Inspect and maintain tools and equipment used for material handling.

3. Quality Control

Check and measure forged products to ensure they meet specifications.

- Identify and correct defects in forged components.

- Maintain records of quality control inspections and tests.

4. Safety and Maintenance

Follow safety protocols to ensure a safe working environment.

- Inspect and maintain forging equipment regularly.

- Report any potential hazards or safety concerns to supervisors.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips and hacks to help you ace your Forge Hand interview:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific Forge Hand position you are applying for.

- Visit the company’s website to learn about their mission, values, and products or services.

- Review the job description carefully to understand the key responsibilities and requirements of the role.

2. Practice Answering Common Interview Questions

There are certain interview questions that are commonly asked in Forge Hand interviews. Practice answering these questions in advance so that you can deliver clear and concise responses during the interview.

- Tell me about your experience in operating forging equipment.

- How do you ensure the quality of forged products?

- What safety precautions do you take when working in a forge shop?

3. Highlight Your Skills and Experience

During the interview, be sure to highlight your skills and experience that are relevant to the Forge Hand position.

- Emphasize your ability to operate and maintain forging equipment safely and efficiently.

- Showcase your knowledge of quality control processes and your commitment to producing high-quality products.

- Provide specific examples of your work experience that demonstrate your skills and abilities.

4. Be Enthusiastic and Professional

Throughout the interview, maintain a positive and enthusiastic attitude. Show the interviewer that you are genuinely interested in the position and that you have the skills and experience to be successful in the role.

- Dress professionally and arrive on time for your interview.

- Maintain eye contact and speak clearly and confidently.

- Thank the interviewer for their time and consideration.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Forge Hand, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Forge Hand positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.