Are you gearing up for an interview for a Forge Tender position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Forge Tender and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

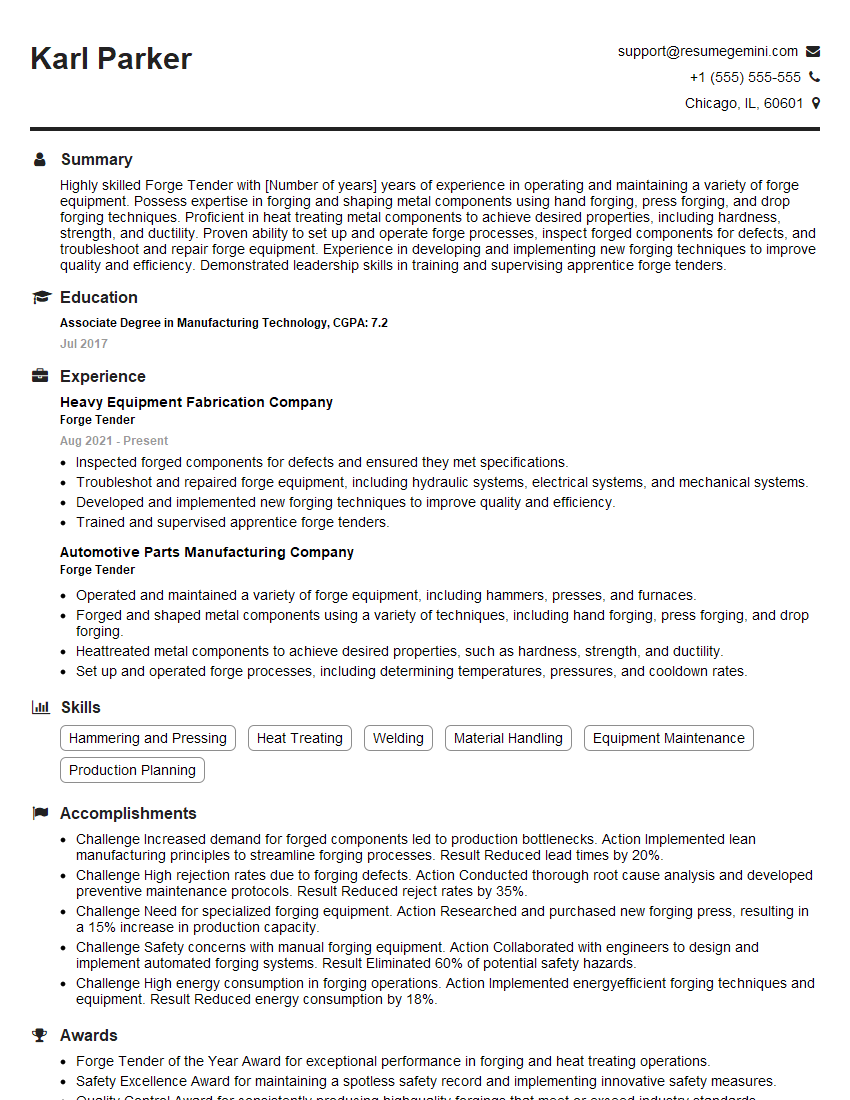

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Forge Tender

1. What are the different types of forging processes?

- Open-die forging: In this process, the metal is placed between two dies that do not have a closed impression. The metal is then shaped by blows from a hammer or press.

- Closed-die forging: In this process, the metal is placed in a closed die that has a cavity that matches the shape of the finished part. The metal is then shaped by blows from a hammer or press.

- Roll forging: In this process, the metal is passed between two rolls that have a pattern that matches the shape of the finished part. The metal is shaped by the pressure of the rolls.

- Swaging: In this process, the metal is shaped by blows from a hammer or press that is guided by a swage block.

- Upsetting: In this process, the metal is shaped by blows from a hammer or press that is applied to the end of the metal.

2. What are the different types of forging equipment?

Power hammers

- Mechanical power hammers

- Hydraulic power hammers

- Pneumatic power hammers

Presses

- Mechanical presses

- Hydraulic presses

- Pneumatic presses

Rolls

- Two-high rolls

- Three-high rolls

- Four-high rolls

Swages

- Hand swages

- Power swages

Upsetters

- Mechanical upsetters

- Hydraulic upsetters

- Pneumatic upsetters

3. What are the different types of forging materials?

- Iron

- Steel

- Aluminum

- Copper

- Titanium

4. What are the different properties of forged materials?

- High strength

- Good toughness

- Excellent wear resistance

- Good corrosion resistance

- Low weight

5. What are the applications of forged materials?

- Automotive parts

- Aerospace parts

- Medical devices

- Construction materials

- Tools

6. What are the safety precautions that must be taken when working with forging equipment?

- Wear proper safety gear, including gloves, safety glasses, and earplugs.

- Keep the work area clean and free of debris.

- Never operate forging equipment without proper training.

- Be aware of the location of all safety controls and know how to use them.

- Never place your hands or any other body parts near moving parts.

7. What are the troubleshooting tips for forging equipment?

- If the equipment is not working properly, first check the power supply and make sure that the equipment is properly plugged in.

- Next, check the hydraulic fluid level and make sure that it is at the proper level.

- If the equipment is still not working properly, call a qualified technician.

8. What are the maintenance tips for forging equipment?

- Keep the equipment clean and free of debris.

- Lubricate the equipment regularly.

- Inspect the equipment regularly for any signs of wear or damage.

- Have the equipment serviced by a qualified technician on a regular basis.

9. What are the career advancement opportunities for Forge Tenders?

- Supervisor

- Manager

- Quality control inspector

- Production engineer

- Sales representative

10. What are the challenges of working as a Forge Tender?

- The work can be physically demanding.

- The work can be dangerous.

- The work can be repetitive.

- The work can be dirty.

- The work can be noisy.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Forge Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Forge Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Forge Tender, you will be responsible for operating and maintaining forge equipment to produce metal components. Your key responsibilities will include:

1. Setup and Operation

Setting up and operating forging equipment, including hammers, presses, and furnaces.

- following blueprints and specifications to ensure accurate production.

- Monitoring equipment performance and making adjustments as needed.

2. Material Handling

Loading and unloading materials into and out of forge equipment.

- Ensuring that materials are properly heated and positioned for forging.

- Inspecting finished products for defects.

3. Equipment Maintenance

Performing routine maintenance on forge equipment, including lubrication, cleaning, and repairs.

- Identifying and troubleshooting equipment problems.

- Making necessary repairs or adjustments.

4. Safety

Maintaining a safe work environment in the forge.

- Following all safety procedures and regulations.

- Using proper personal protective equipment.

- Reporting any unsafe conditions or practices.

Interview Tips

Preparing for an interview for a Forge Tender position requires understanding the key responsibilities of the role and tailoring your answers to highlight your relevant skills and experience. Here are some tips to help you ace your interview:

1. Research the Company

Research the company you are interviewing with to understand their products, services, and culture. This will help you tailor your answers to the specific needs of the company and demonstrate your interest in the position.

2. Practice Your Answers

Prepare for common interview questions by practicing your answers in advance. Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your experience.

3. Highlight Your Skills and Experience

Emphasize your skills and experience that are relevant to the job description. For example, if the job requires experience in operating specific forge equipment, highlight your proficiency in using those machines.

4. Be Enthusiastic

Show your enthusiasm for the role and the opportunity to contribute to the company’s success. Share your passion for forging and your eagerness to learn and grow in the industry.

5. Ask Questions

Asking thoughtful questions at the end of the interview demonstrates your engagement and interest in the position. Use this opportunity to clarify any aspects of the role or the company that you are curious about.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Forge Tender role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.