Are you gearing up for a career in Forgesmith? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Forgesmith and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

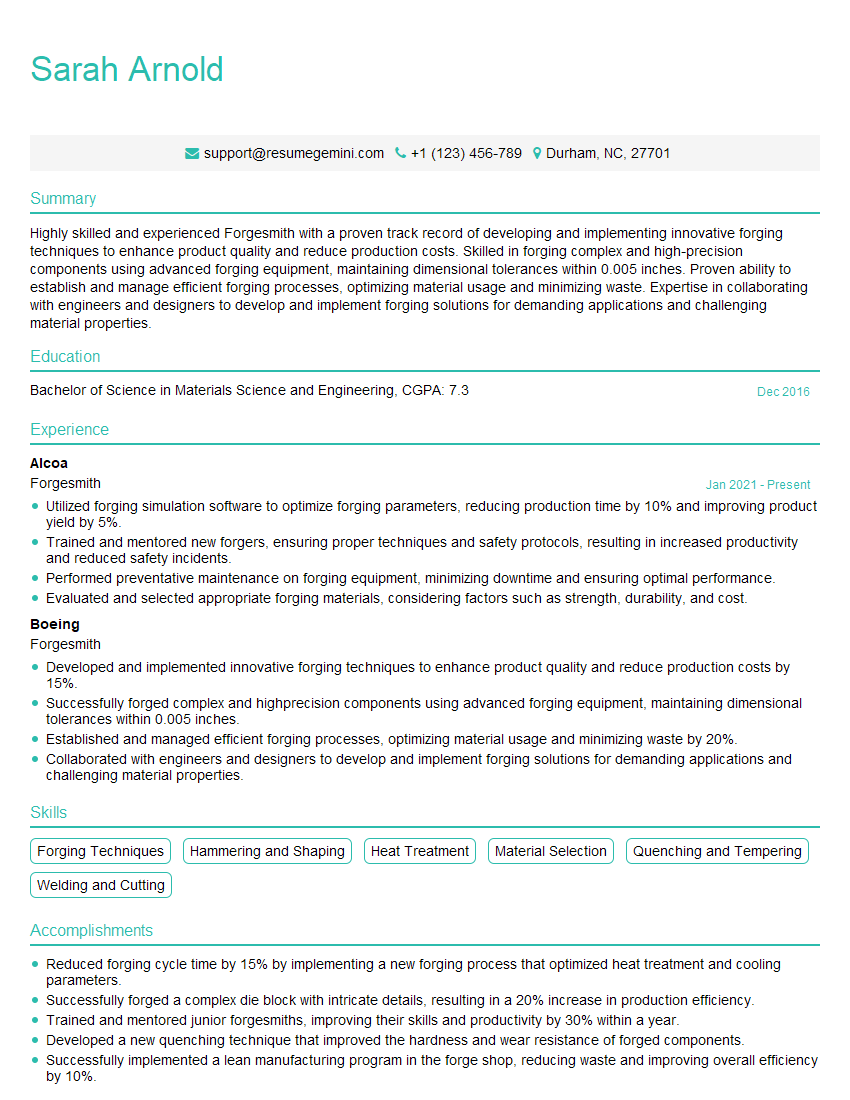

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Forgesmith

1. Walk me through the process of forging a sword from start to finish.

A step-by-step description of the forging process, including material preparation, heating, shaping, quenching, and tempering.

2. What are the different types of forging techniques, and when would you use each one?

Types of Forging Techniques

- Hammer forging

- Press forging

- Roll forging

- Drop forging

When to use each technique

- Hammer forging: Small, intricate parts

- Press forging: Large, flat parts

- Roll forging: Continuous production of long, thin parts

- Drop forging: Mass production of complex shapes

3. How do you ensure the quality of your forged products?

Quality control measures, such as inspection, testing, and documentation.

4. What are the common defects that can occur during forging, and how do you prevent them?

- Cracks

- Inclusions

- Voids

- Warpage

Prevention methods, such as proper material selection, forging temperature control, and heat treatment.

5. What are the different types of forge equipment, and what are their advantages and disadvantages?

- Coal forge

- Gas forge

- Electric forge

Advantages and disadvantages of each type.

6. What are the safety precautions that must be taken when forging?

- Proper ventilation

- Protective clothing

- Eye protection

- Fire extinguisher

7. How do you stay up to date on the latest forging techniques and technologies?

- Trade shows

- Workshops

- Online resources

- Technical journals

8. What are your strengths and weaknesses as a forgesmith?

- Strengths: Attention to detail, precision, problem-solving skills

- Weaknesses: Limited experience in certain forging techniques

9. Why are you interested in this position?

Specific reasons for applying to the company and role, including alignment with career goals and company values.

10. What are your salary expectations?

Research industry benchmarks and consider experience and qualifications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Forgesmith.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Forgesmith‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Forgesmith is a skilled artisan who specializes in forging and shaping metal, typically creating functional or decorative items. The key job responsibilities include:

1. Forging and Shaping Metal

Using a forge and a variety of tools, a Forgesmith heats, hammers, and shapes metal to create various forms and components.

- Selecting the appropriate metals and alloys based on the desired properties.

- Heating the metal to precise temperatures using a forge or other heating equipment.

- Using hammers, anvils, and other tools to shape and form the metal into the desired shape and dimensions.

2. Fabricating Metal Objects

Understanding metalworking techniques to create both functional and decorative items such as tools, furniture, and artwork.

- Designing and creating blueprints or templates for the fabrication process.

- Cutting, welding, and assembling metal components to form the desired objects.

- Ensuring the structural integrity and functionality of the fabricated metal objects.

3. Heat Treating and Finishing

Applying heat treatment techniques to enhance the properties of the forged metal and improve its durability, strength, and aesthetics.

- Subjecting the forged metal to specific heating and cooling cycles to alter its molecular structure.

- Using various finishing techniques such as polishing, sanding, and painting to enhance the appearance and corrosion resistance of the metal objects.

4. Maintenance and Repair

Maintaining equipment and tools used in the forging process, as well as repairing or restoring forged metal items.

- Inspecting and calibrating equipment regularly to ensure optimal performance.

- Troubleshooting and repairing any issues that arise with the forging equipment or fabricated metal objects.

- Restoring damaged or worn-out forged metal items to their original condition.

Interview Tips

To prepare for an interview for the position of Forgesmith, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s background, values, and the specific requirements of the Forgesmith role. This will enable you to align your skills and experiences with the company’s needs.

- Visit the company’s website and social media pages to gather information.

- Read industry publications and articles to stay updated on current trends and techniques in metalworking.

2. Highlight Your Skills and Experience

Emphasize your proficiency in forging techniques, metalworking knowledge, and fabrication experience. Provide specific examples of projects you have worked on and the outcomes you achieved.

- Showcase your ability to create intricate designs and execute them precisely.

- Quantify your accomplishments whenever possible, using metrics to demonstrate your impact.

3. Prepare for Technical Questions

Review fundamental concepts in metallurgy, heat treatment, and metalworking processes. Be prepared to discuss your understanding of different types of metals, alloys, and their properties.

- Practice answering questions about forging techniques, such as hammering, welding, and heat treatment.

- Research industry-specific software and tools used in metalworking and be prepared to demonstrate your proficiency.

4. Showcase Your Passion and Creativity

Forging is an art form that requires passion and creativity. Convey your enthusiasm for the craft and highlight any unique or innovative approaches you bring to your work.

- Share examples of personal projects or hobbies that demonstrate your creativity and artistic abilities.

- Discuss your aspirations for the role and how you envision contributing to the company’s success.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Forgesmith role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.